MAAG Company

The MAAG Group comprises successful and renowned companies, each with their own impressive history. Automatik Plastics Machinery, Ettlinger Kunststoffmaschinen, Maag Pump Systems, Gala Industries, Reduction Engineering Scheer and Xantec Steuerungs- und EDV Technik are today the strong and innovative product brands of the MAAG Group.

The history of the MAAG Group thus begins in the late 19th century, with the establishment of Scheer as a metal foundry and machine factory in Stuttgart, Germany, in 1890. Maag Pump Systems was founded in 1913. Automatik Plastics Machinery was founded in 1947. Gala Industries was founded in 1959, and Ettlinger Kunststoffmaschinen in 1983. The youngest member of MAAG Group – Xantec Steuerungs- und EDV-Technik was founded in 1994. Over the decades, they have all grown into experts in the various fields of polymer production and processing.

All the members of the MAAG Group contribute their supreme expertise and years of experience in developing and manufacturing superb machines, plants, systems, and software – and will continue doing so in the future. The bundling of core competencies, industry best practices, the attentive maintenance of existing business relationships and creation of new ones, all provide the foundations for maximum customer satisfaction throughout the Group.

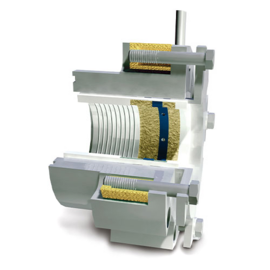

Viscoseal

Seal for highly viscous fluids, extrusion gear pump systems, melt pumps, and polymer extrusion

The viscoseals are available for highly viscous fluids which are used for extrusion gear pump systems. The seal is contactless and dynamic. It has a simple design and has only one sealing part. A cooled model is available for the polymer extrusion industry is available and it is virtually maintenance free.

For corrosive fluids: Suitable

For abrasive fluids: Good fit

TA-Luft certified: No

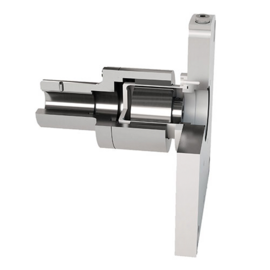

Magnetic Coupling

Sealed design with our double containment shell for chemical pumps as a industrial application

MAAG offers Magnetic Couplings with our double containment shell for chemical pumps. The magnetic couplings provide a hermetically sealed design for chemical transfer pumps and is virtually maintenance free. The couplings come in special designs for industrial applications with suction pressures up to 200 bar.

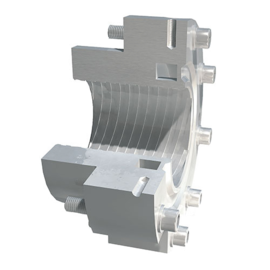

Vispac

Seal for polymer gear pumps and polymer pump systems and applications

High reliability and functionality are crucial for a seal in the polymer application discharging process for guaranteeing optimized product quality and line availability. The vispac® shaft seal is known for its robustness and reliability and especially for its easy handling. This low-maintenance seal is a proven combination of the viscoseal system and sealed packing glands for polymer pump systems.

Extremely large range of applications

Reliability and safety

Low wear and low maintenance

Simple and reliable adjustment of the seal control pressure

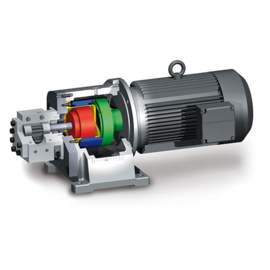

Mag drive

Chemical pumps and chemical transfer pumps for industrial applications

Magnetic drives are hermetically sealed, thereby guaranteeing that environmentally hazardous, poisonous, and malodorous substances are pumped safely by chemical transfer pumps. The product chamber in the gear pump is completely separated from the environment by a containment shell. The torque is transferred from motor shaft to pump shaft without contact by means of heavy-duty permanent magnets. This design makes the magnetic couplings extremely safe and virtually maintenance-free for the industrial application.

High suction pressures (standard to 25 bar, in special designs up to 200 bar)

Virtually maintenance-free

Optimized safety and leak sealing

Hermetically-sealed design

Long service life

Low maintenance costs

Maxx BF

Automatic self cleaning backflush screen changer for filtration systems

Maax® BF is MAAG’s well-proven control system for the fully automatic backflush screen changers. It allows the processor of highly contaminated polymer melts simple handling of the backflush screen changer and fully automatic screen cleaning for multiple use of the built-in screens. The automation system is particularly well suited for retrofitting extrusion lines with automatic self cleaning screen changers with backflush function. Operation, control, regulation, and monitoring of operating parameters are simplified. Process and operation reliability of the filtration systems of the entire system are increased.

Simple and clear operation of filter and system functions

Increased productivity through storage of recipes in parameter lists

Integrated temperature control of the system components

Rapid error detection via clear text messages

Scalable visualization of different operation parameters in a trend display

Increased productivity

Maax 3S

Automation system for retrofitting in extrusion lines

The automation system maax® 3S simplifies the operation, control, regulation, and monitoring of the operating parameters. Production data are displayed transparently and operation is simple and intuitive. Process and production safety of the line are increased. The maax® 3S automation system is particularly suitable for the retrofitting of gear pumps or screen changers in extrusion lines.

Simple and clear operation of the start-up and shutdown routines

Modular expansion to include screen changer controllers

Quick and precise control of the extruder or pump speeds

Independent start-up and production control of the pump speed

Integrated temperature control of the line components

Fast troubleshooting thanks to plain text messages

Maax 100S / 400S / 600S

Extrusion gear pump and melt pump system for the polymer extrusion industry

The maax® automation system simplifies operation, control, adjustment, and monitoring of the operating parameters. This guarantees optimum protection and operation of the extrusion gear pump system, melt pump system, and screen changer. Process and operational reliability of the entire system is increased. The maax® 100S automation system is the ideal solution for integrating melt pumps and screen changers into the extrusion line. maax® 400S is for upgrading coextrusion lines. The maax® 600S automation system is the ideal solution for equipping complete and complex extrusion and compounding plants in the polymer extrusion industry.

Simple and clear operation of the line-start and stop proceures

Increased productivity, by saving recipies in parameter lists

Rapid and precise control of extruder and pump speed, depending on application

Integrated temperature control of system components

Quick error detection by plain text messages

Scalable visualisation of various operating parameters in a trend display

Additional for maax® 100S/400S/600S: configurable System and Software configuration

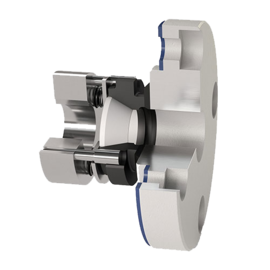

Single Mechanical Seal

Chemical pumps and chemical transfer pumps for abrasive fluids in industrial applications

This seal on the chemical transfer pump is applicable for high temperatures. A different material combination is available for aggressive and corrosive media. The sealing ring in SSiC can be used for abrasive fluids in industrial applications.

For corrosive fluids: Good fit

For abrasive fluids: Good fit (with SSiC)

TA-Luft certified: No

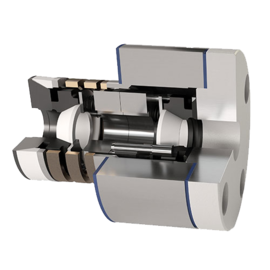

Double Mechanical Seal

Seal with buffer fluid for chemical pumps and chemical transfer pumps in industrial applications

The Double Mechanical Seal is a MAAG brand for industrial application and chemical pumps. It has a robust design with buffer fluid. Therefore, it is suitable for corrosive and abrasive applications. The sealing rings are available in carbon and SSiC (sintered silicon carbide ceramic) for chemical transfer pumps.

Blendrex®

Polymer processing, polymer systems, and polymer applications for extrusion in the polymer industry

MAAG specializes in the design and application of blendrex® heat exchangers used to preheat polystyrene melt prior to devolatilization and to cool polyester prior to spinning or pelletizing by polymer processing. blendrex® heat exchangers are problem solvers for many types of difficult heating and cooling polymer applications.

Significantly improve heat transfer rates of polymers and other viscous products. Three to seven times the rate obtainable compared to an “open tube” (no blendrex® elements) design

Provide a shorter product residence time inside the unit

blendrex® tube is a “plug flow” device

Tubes eliminate localized “hot spots”, and provides uniform temperature profile across the tube section

Contain alternating helical twist elements to obtain the high performance capabilities

TUMBLER™

Pellet Processing Systems for the Plastics and Adhesive Industries

The Gala Tumbler may be used as a defluidizer or dryer for brittle products, a pellet coater for tacky products, or a pellet classifier for any type of product.

Aluminum case

Stainless steel drum

Folding doors

Leveling equipment

The drum can be completely removed

May absorb solids or liquids

DURO

Efficient pellet drying technology for abrasive pellets

The DURO belt dryer in combination with the underwater pelletizing systems from Gala and Automatik is the perfect solution for the production of abrasive or brittle pellets such as compounds highly filled with fiber glass or minerals. The drying process does not use any rotating parts and thus is a very gentle process reducing costs related to wear to a minimum.

The most gentle handling of pellets

Minimal dust

High product quality

Minimized life cycle costs