GRMT

A sliding thermocouple (GRMT) is used to measure the temperature inside the polymer melt flow with different sensing depths. The temperature sensing position can vary from the chamber wall to the center of the chamber during standard flow and pressure conditions without removing the sensor from the adapter. The offset in the design of the temperature sensor housing allows the user to select and monitor the displacement depth of the sensor in which it is currently located.

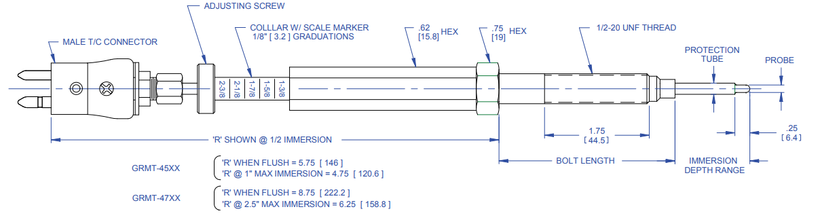

GRMT - Dynisco temperature sensor with adjustable immersion depth.

Cable to GRMT temperature sensor

Cable to GRMT temperature sensor

Cable to GRMT temperature sensor

Inquiry system

Configure your own product according to your requirements and needs. If you are unsure of the configuration, provide us in the notes the necessary information about the existing sensor or product, even a competitor. We will be happy to help you find an alternative Dynisco product. If your request is urgent, let us know. We will do our best to help you resolve this situation to your satisfaction as quickly as possible. If we have all the information, we are able to offer a model with minor differences, which is in stock and you can have another product available the next day.

If you need more information do not hesitate to contact us.

Dynisco Configuration Code:

Reliable and safe temperature measurement system

Melt Temperature Probe Series GRMT

The Graduated Retractable Melt Thermocouple (GRMT) is used to measure temperatures inside the polymer melt stream. The depth of immersion of the junction into the hot melt stream can be varied from zero to mid-stream during maximum flow and pressure conditions, without removing the sensor from the adapter. Using the graduations on the stem of the temperature sensor allows the user to choose and monitor the specific depth at which the junction is in the melt stream.

Features & Benefits

TC Junction can be centered in hot melt stream

Retractable from flush to 2.5”

Up to 900°F (480°C) melt temperatures

All stainless steel construction

Exposed junction

1/2-20 UNF mounting configuration

Obtains temperature profiles without stopping the process

Designed for extrusion applications

Corrosion resistant option available – HAST C

Directly replaces any standard melt thermocouple

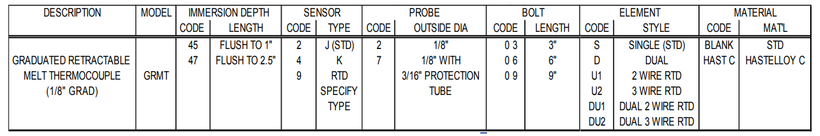

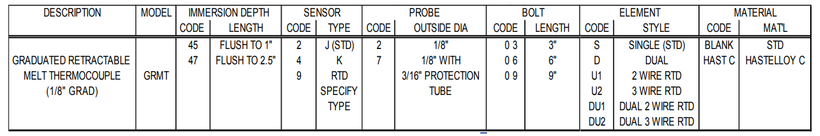

Ordering Guide for GRMT Series

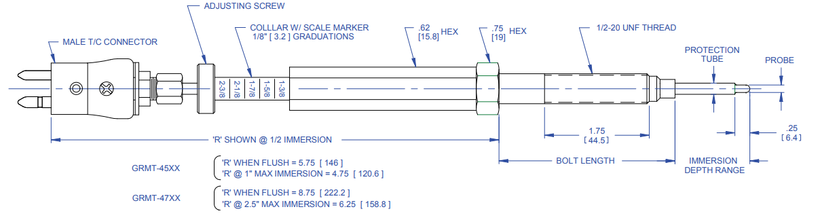

GRMT - Dimensions

All dimensions are inches (mm) unless otherwise specified.

Installation of transducers into improperly cleaned or sized holes is one of the major causes of damage to these instruments. With this kit, the .312" tip diameter hole, the 45 degree seating surface, and the .451" hole can be cleaned. The kit includes a gauging plug which is used to verify that the hole has been correctly machined and cleaned. M10 and M18 cleaning kits also available.

The Dynisco Transducer Mounting Hole Machining Tool Kit contains all of the necessary drills and taps to prepare a standard 1/2 - 20 UNF transducer mounting hole and the 45 degree seat. All tools included in this kit are made of premium grade, high strength tool steel. Care should be taken in the use of proper speeds and feeds, lubricants, and a method to assure continual alignment of each progressing tool. M10 and M18 kits are also available.

The 1496 series temperature controllers represent an economical solution for precise temperature control of the machine. Thanks to its DIN size and several output configurations, the controller is suitable for twin and single screw extruders, both for screw temperature zones and for adapter zones, together with heating / cooling for individual zones.

The 1498 series temperature controllers represent an economical solution for precise temperature control of the machine. Thanks to its DIN size and several output configurations, the controller is suitable for twin and single screw extruders, both for screw temperature zones and for adapter zones, together with heating / cooling for individual zones.

The UPR900 is a compact 1/4 DIN process indicator. The UPR900 can display your choice of engineering units related to a selectable range of input types. Add an optional secondary input for an all-in-one display of polymer melt pressure and temperature. The secondary input can be strain gauge to indicate differential pressure measurement. The UPR900 includes two standard assignable alarms with the option to add a 3rd.

The ATC990 with a graphical/text LCD display is a universal input process controller with advanced functionality including Trend views as well as Digital Inputs, USB and data logging options. It provides a cost-effective way to control a single process parameter, such as for a plastics extruder. Designed to improve user efficiency many features are integrated to reduce commissioning time, simplify operation and minimize maintenance downtime. Reliably auto-tune and alarm on strain gauge, DC voltage, temperature or current inputs.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.