What MAAG addresses in practice

In modern polymer operations, it is essential to maintain a stable process, consistent quality, and the ability to respond quickly to changes in material and production conditions. MAAG builds on a “masterly overview” – broad expertise across the process steps that enables the company to design solutions “from a single source” and align components into a fully integrated system.

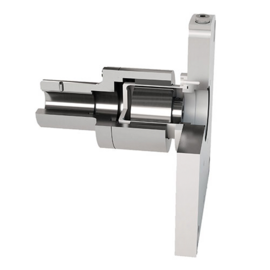

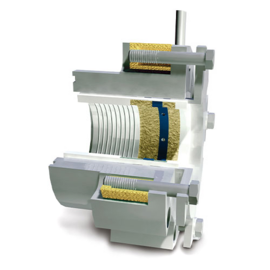

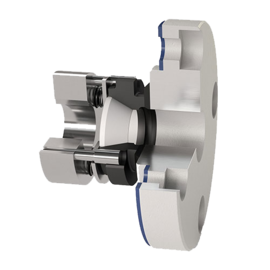

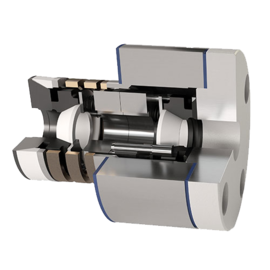

Typical solutions combine gear pumps (flow/pressure stabilization), melt filtration (contaminant removal and process stability), pelletizing systems (various pellet shapes and types), and, depending on the application, also pulverizing and recycling solutions.

The Group is represented in the market by a portfolio of brands: AMN, AUTOMATIK, ETTLINGER, GALA, MAAG, REDUCTION, SCHEER, WITTE, XANTEC.

- More stable processes and quality through alignment of pumps, filtration, and downstream technologies

- Higher throughput and efficiency thanks to systems engineered as an integrated whole

- Support across the equipment lifecycle – service, spare parts, upgrades, training