Digital Encoder

The Digital encoder provides a high precision measurement of piston displacement during Method A/B and B tests.Automatic Sample Cutter

Automatic Sample Cutter

Cuts samples automatically at defined cut times of Method A and Method A/B Testing. Will also cut sample at end of pre-heat melt time of a test, regardless of method. Leads to more consistent

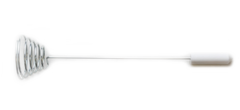

Force Packer

The Force Packer is designed to apply a constant force to compress the sample once the opera-tor has loaded the polymer sample. This constant force promotes a level of confidence by removing variability between operators.

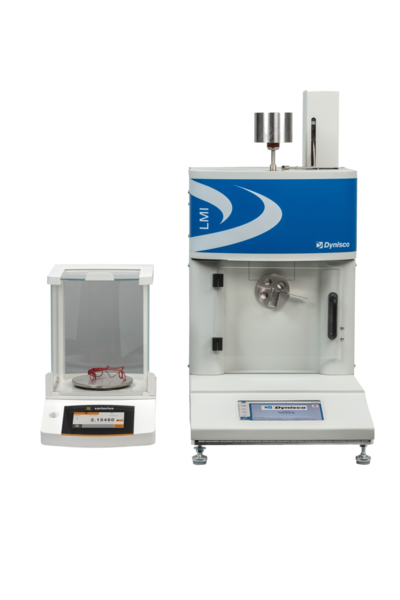

LaVA Suite Software

The redesigned software is capable of producing customized series of data including informa-tion about testing conditions, melt index values, shear stress, shear rate, viscosity, and apparent melt density. Through the use of this software option, these values are recorded and may be reported through various out-puts and formats.

Weight Lift System

The weight lift system allows for effortless weight application. By storing all of the weights in a stack above the LMI, selecting the weight load is as simple as moving the selector pin from one slot to the next eliminating the need for lifting weights manually. The lift system also offers a mid-position stop and hold feature for highly viscous materials.

Languages

Supports 12 languages: English, Chinese, Dutch, German, Polish, Japanese, Portuguese, Spanish, Italian, Czech, French, Russian.