FCR-R - Rheometer

Specifically designed for the synthetic fiber production industry, the Dynisco FCR-R series can be configured to measure a range of apparent shear viscosities, dual melt flow rate, simultaneous melt flow rate and extensional viscosities using the Cogswell Equations. The FCR-R system consists of two parts: a rheometer head and a rheometer control unit (RCU). The rheometer head is connected directly to the process which samples, conditions, and measures the melt viscosity of the molten resin through two separate dies. The RCU controls the rheometer test parameters (temperature, pressure and rate) and takes in data from the measurement head as well as provides outputs of computed results.

Features:

■ On-line apparent viscosities over a broad shear rate range

■ Unique dual capillary design with return stream

■ On-line measurements of polymer extensional properties

■ Data exchange by analog and digital input/outputs

■ Simple calibration

Online Rheological Measurement Experience the Benefits of Online Rheology Measurement

The Flow Characterization Rheometer

The measurement head samples molten polymer from the process through a heated transfer line. A three gear metering pump then drives the polymer melt through two separate capillary dies at a precisely controlled rate.

When the system is run at constant pressure (stress) and the flow rate is determined, continuous measurements of the MFR or MFR/ viscosity may be obtained. When it is run at constant rate the simultaneous calculation of apparent viscosities at different shear rates are possible. Extensional viscosities can be obtained when a ”zero length” die is used as one of the capillaries.

Rheometer Control Unit

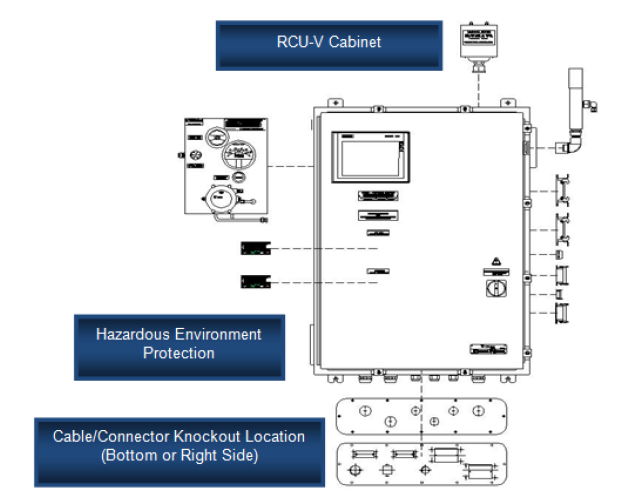

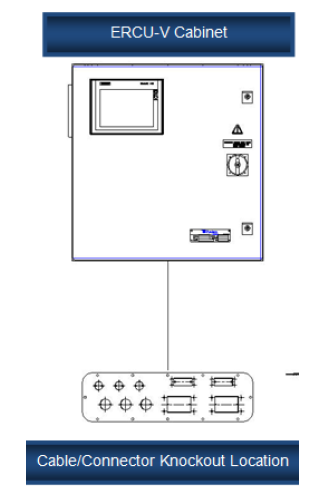

The Rheometer Control Unit is contained in a NEMA 4 (IP 54) box that may be located in the control room or on the process floor. Programming of the control functions and output displays are achieved via a local color display with a touch screen interface. The RCU can communicate with a Distributed Control System (DCS) through its analog and serial outputs. The RCU operates independently and will continue its control and analysis functions in the event of a DCS failure.

The Rheometer Control Unit is contained in a NEMA 4 (IP 54) box that may be located in the control room or on the process floor. Programming of the control functions and output displays are achieved via a local color display with a touch screen interface. The RCU can communicate with a Distributed Control System (DCS) through its analog and serial outputs. The RCU operates independently and will continue its control and analysis functions in the event of a DCS failure.

Options

■ Various Capillaries

■ Process Isolation Valve

■ Standing Console or Wall Mount for RCU

■ Additional I/O

■ Heated Transfer Section

■ Modbus RTU or TCP, Profibus, Profinet, Open TCP

■ Hazardous ocation

■ NEMA 4X

■ Simple calibration

Performance Characteristics

| Melt Flow Index: | 0.02 - 5000 g/10 min |

|---|---|

| Viscosity Range: | 10 - 105 Pa.S |

| Shear Stress: | 150 - 1.5 x 105 Pa |

| Shear Rate: | 1 – 5000 s-1 (standard die) max. 50,000 s-1 (special die) |

Dies: |

|

| Viscosity: | 1 - 5mm, 10 do 30:1 L/D |

| Melt Flow Index: | 3.8182:1 L/D |

| Special Dies: | Na życzenie |

| Temp. Range: | 40 – 80°C |

| Pressure Range: | 3 x 105 – 3.5 x 107 Pa |

| Metering Pump: |

0.30 cm3 / RPM (standard) |

| Pump Speed: | 2 – 40 RPM |

| Polymer Flow: | 680 g/hour (average) |

Measurement and Control Functions

Shear Stress Mode: |

|

|---|---|

| Set point: | Pressure |

| Measurement: | Melt Flow Index |

Shear Rate Mode: |

|

| Set point: | Pump Speed |

| Measurement: | Apparent Viscosity |

| Temperature control: | 2 Heating Zones Pump and Capillaries |

RCU Specifications

| Electrical Cabinet: | NEMA 4 (IP 54) |

|---|---|

| CPU: | S7-300 |

| Operator Interface: | Touch screen display |

Analog Outputs: (4 – 20 mA Standard)

| Temperature: | Pump Temperature Capillary Temperature Melt 1 & 2, Average, Aux |

|---|---|

| Pressure: | Transducer 1,2,3 Delta Pressure 1,2 |

| Rheological: | MFR, Shear Rate, Shear Stress, Melt Viscosity, Relative Viscosity, Intrinsic Viscosity |

Digital Inputs: (NO/NC Dry Contacts)

| Test (motor): | on/ off |

|---|---|

| Heat: | on/ off |

| Mode: | pressure / speed |

Digital Outputs: (NO/NC)

| Fault |

|---|

| Alarm |

| Local/ Remote |

| Motor on/ off |

| Material in range |

Electrical Specifications

| System Voltage: | 220-240V Single Phase 50/60 Hz |

|---|---|

| Power: | 2000 W (max) |

Dimensions RCU:

Dimensions E-RCU:

Certification Approval

|

EU Declaration of Conformity |

|

ISO 9001:2015 |

|

EAC - The Eurasian Conformity mark |

|

RoHS Compliance Fact Sheet |