ViscoSensor

Specially designed for the thermoplastic polymers industry. ViscoSensor provides continuous measurement of melt flow index or apparent viscosity or intrinsic viscosity (IV) directly on the production line. The ViscoSensor system consists of two parts:

The Viscosensor RSU (Rheologic Sensing Unit) is directly connected to the process, where it samples and measures the polymer melt flow index, and either the RCU or e-RCU, which controls the viscosensor system, controls the process parameters temperature, pressure, speed, provides outputs for calculate the results and, if necessary, ensure communication with an external distributed control system.

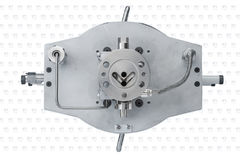

THE VISCOSENSOR RSU

The ViscoSensor employs a stacked pair of metering pumps to isolate it from the process, to direct the molten polymer across interchangeable capillaries, and to pump the molten polymer back into the process. A three wire platinum RTD is used to control and measure the temperature of the molten polymer. Two Dynisco Vertex Mercury Free pressure transducers (now comes standard) mounted directly before and after the die, are used to capture the pressure drop across the capillary.

The ViscoSensor employs a stacked pair of metering pumps to isolate it from the process, to direct the molten polymer across interchangeable capillaries, and to pump the molten polymer back into the process. A three wire platinum RTD is used to control and measure the temperature of the molten polymer. Two Dynisco Vertex Mercury Free pressure transducers (now comes standard) mounted directly before and after the die, are used to capture the pressure drop across the capillary.

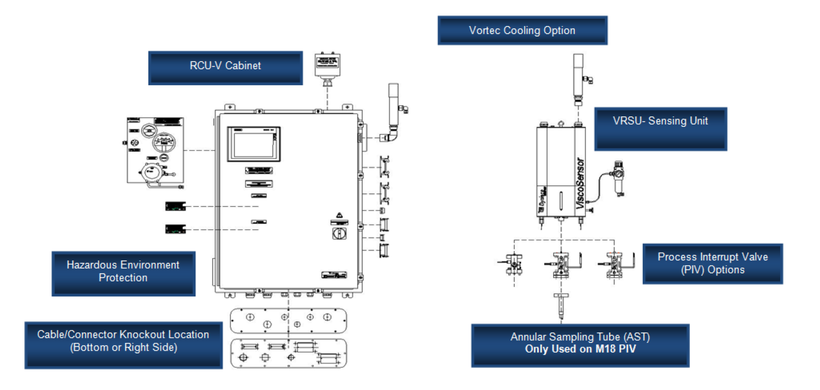

VISCOSENSOR RCU: ULTIMATE PERFORMANCE

Our high performance RCU combines the rheological properties of a Laboratory Capillary Rheometer with MFI readings delivered by a Melt Flow Indexer. It has been updated with a Siemens S7-1500 PLC with a Siemens 7” (178mm), Comfort Panel Touch Screen HMI. This combination provides increased processing pow-er and hi-end graphics enabling the RCU to provide +/- .5% Full Scale Accuracy. This allows the RCU to better align measurements with those taken from laboratory instruments. Furthermore, it is certified for hazardous environments as needed.

Our high performance RCU combines the rheological properties of a Laboratory Capillary Rheometer with MFI readings delivered by a Melt Flow Indexer. It has been updated with a Siemens S7-1500 PLC with a Siemens 7” (178mm), Comfort Panel Touch Screen HMI. This combination provides increased processing pow-er and hi-end graphics enabling the RCU to provide +/- .5% Full Scale Accuracy. This allows the RCU to better align measurements with those taken from laboratory instruments. Furthermore, it is certified for hazardous environments as needed.

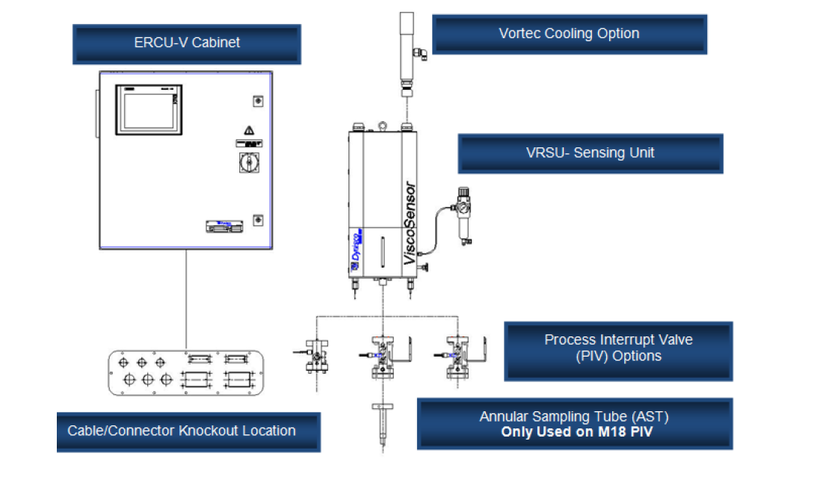

VISCOSENSOR e-RCU: PERFORMANCE SIMPLIFIED

The ViscoSensor e-RCU offers a simplified PLC with the digital and analog I/O that most plants would need for a cost effec-tive approach to measuring online rheology. It has a Siemens S7-1200 PLC with a Siemens 7” (178mm) Comfort Panel Touch Screen HMI. This combination provides the system with processing power and hi-end graphics allowing the e-RCU to provide +/- 2% Full Scale Accuracy. The e-RCU provides the processor the ability to measure Melt Flow Ratio, Relative Viscosity, Intrinsic Viscosity, and Melt Viscosity in typical end-user environments. All of which create a cost-effective system that reduces the risk of failure to an acceptable level. If conditions change and the system is needed in a hazardous and/or classified location, compatibility with the standard RCU allows for an easy upgrade.

PERFORMANCE CHARACTERISTICS

| Melt Flow Index | 0.1 - 25000 g/10 min |

|---|---|

| Viscosity Range | 10 – 105 Pas |

| Shear Stress | 150 - 1.5 x 105 Pa |

| Shear Rate | 0.1 – 7500 s-1 (standard die) max 50,000 s-1 (special die) |

| Dies | |

| Temp. Range | 40 – 350°C |

|

Pressure Range |

3 x 105 – 3.5 x 107 Pa |

| Metering Pump |

0.16 cm3 / RPM (standard) 0.297 cm3/ RPM (optional) 0.584 cm3/ RPM (optional) |

| Pump Speed | 3 – 75 RPM |

| Polymer Flow | 225 g/hour (average) |

MEASUREMENT AND CONTROL FUNCTIONS

| Test Modes | |

|---|---|

| Shear Stress Mode | |

| Set point | Pressure |

| Measurement | Melt Flow Index |

| Shear Rate Mode | |

| Set point | Pump Speed |

| Measurement | Apparent Viscosity |

| Temperature Control | 3 Heating Zones |

ANALOG OUTPUTS: (4 – 20 MA STANDARD)

| Options | • Melt Flow Index • Apparent Viscosity • Melt Temperature • Melt Pressure • Pump Speed • Temp. Pump Zone • Temp. Die Zone |

Select any 2 of the following:

|

|---|

ELECTRICAL SPECIFICATION

| System Voltage | 220-240V Single Phase, 50/60 Hz |

|---|---|

| Power | 2000 W (max) |

DIGITAL INPUTS

| Weight | 45 lbs. |

|---|---|

| Height | 25 in. (63.6 cm) |

| Width | 11.1 in. (28.2 cm) |

| Depth | 9.9 in. (25.2 cm) |

| Mounting Configuration | Vertical (Stand for horizontal- only if using M18 pressure port) |

Certification Approval

|

EU Declaration of Conformity |

|

ISO 9001:2015 |

|

EAC - The Eurasian Conformity mark |

|

RoHS Compliance Fact Sheet |