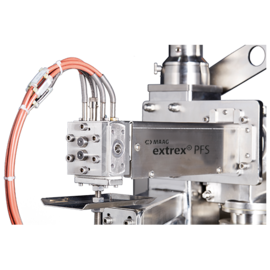

extrex® PFS – 20GP

The extrex® PFS gear pumps are specially designed for applications in the pharmaceutical industries. Such applications require specific design characteristics: high discharge pressure capability, constant throughput, gentle conveying, and narrow temperature ranges. In such an environment, the proven extrex® gear pumps unfold their full potential.

Technical data

| Technical data |

extrex®

20 GP |

extrex®

21 GP |

extrex®

22 GP |

extrex®

28 GP |

extrex®

36 GP |

|---|---|---|---|---|---|

| Specific volume [cm 3 / U]: | 1,3 | 2,8 | 4,7 | 10.2 | 25,6 |

| Differential pressure Δp: | max. 250 bar | max. 250 bar | max. 250 bar | max. 250 bar | max. 250 bar |

| Temperature range: | 30° to 200°C | 30° to 200°C | 30° to 200°C | 30° to 200°C | 30° to 200°C |

| Viscosity: | do 30 000 pas | do 30 000 pas | do 30 000 pas | do 30 000 pas | do 30 000 pas |

SELECTION OF TYPICAL PUMPED MEDIA

|

Production of micropellets to prevent grinding

|

|

| Combination of carriers and active nutrients with high viscosity | |

| Application of co-extrusion for uniform layer thicknesses | |

| Process monitoring using pressure sensors and temperature sensors | |

| For extrusion from an extruder or reactor vessel | |

| Silicones | |

| Waxes and paraffins | |

| Emulsifiers | |

| Rubber |

CERTIFICATES

|

ATEX certificate

|

|

|

3.1 certifiká

|

|

| German Air Quality Certificate (TA-Luft) | |

| Performance test certificate |

OPTIONS

|

Electric heating

|

|

| Heated product flanges |

ACCESSORIES

|

Stands, motor flanges and base plate

|

|

|

Flanges for connecting the product

|

|

| Couplings | |

| Motors and reducers | |

| Frequency converters | |

| Shaft sealing systems (with expansion tanks) |