Pružanje inovativnih rješenja

S više od 6 desetljeća posvećenosti pomaganju klijentima, Dynisco pruža alate i usluge za industriju polimera omogućavajući klijentima "prozor u proces".

Današnji klijenti zahtijevaju točne informacije koje će im omogućiti validaciju i, ako je potrebno, prilagodbu njihovog procesa kako bi osigurali da proizvodi koje proizvode zadovoljavaju ili premašuju njihove specifikacije. Informacije koje Dynisco pruža omogućuju našim klijentima održavanje dosljednosti procesa bez obzira na njihovu globalnu lokaciju.

Raznovrstan portfelj Dynisco senzora i opreme za testiranje polimera pruža neke od najtočnijih informacija dostupnih na tržištu za mjerenje polimerske reologije, tlaka i temperature.

Dynisco svojim klijentima omogućuje povezivanje podataka dobivenih iz pilotnih projekata i laboratorijskih okruženja s online proizvodnjom, 24 sata dnevno. Ovi podaci omogućuju trenutnu reakciju i prilagodbu kritičnim parametrima kako bi se osiguralo da se svaka odstupanja promptno isprave radi jamčenja kvalitete i maksimiziranja proizvodnje.

Povijest Dynisco

Poznata diljem svijeta po inovativnim proizvodima za mjerenje tlaka i temperature u industriji plastike, Dynisco već 60 godina razvija inovativna visokokvalitetna rješenja za obradu ekstruzije plastike zahvaljujući stručnom timu inženjera s prosječno 15-20 godina iskustva. Senzori, kontroleri i analitički instrumenti Dynisco dokazali su se pružanjem bolje kontrole, smanjenja vremena zastoja, minimiziranja otpada te neusporedivom pouzdanošću i radnim vijekom. Naša predanost i sposobnost suradnje s vama kako bismo vam pomog li mjeriti, analizirati i opremiti sustave za upravljanje ekstruzijom koji odgovaraju vašim točnim potrebama su neusporedivi. Od inovativnih tehnologija u najkompletnijoj liniji senzora do renomirane kvalitete i performansi indikatora, kontrolera i analitičkih instrumenata.

Senzori Dynisco specifično su dizajnirani za zahtjevno okruženje industrije plastike, a Dynisco je razvio neke od najinovativnijih rješenja za mjerenje u ekstruziji plastike, brizganju i procesnoj kontroli. Proizvodimo širok raspon robusnih senzora za mjerenje tlaka u obliku mV/V, mA, VDC i HART-kompatibilnih senzora za taljenje, zahvaljujući izvrsnosti inženjeringa i iskustvu.

Analitički instrumenti Dynisco

Kvaliteta procesa započinje s upotrebom materijala. Analitički instrumenti Dynisco omogućuju procesoru provjeru specifikacija materijala i optimizaciju uvjeta procesa. Ti instrumenti uključuju uređaje za mjerenje protoka taline, kapilarni reometar i male laboratorijske sustave za miješanje i ekstruziju. Dynisco također nudi najpotpuniju i najtočniju liniju online reometara dostupnih na tržištu danas.

Dynisco nudi potpunu globalnu uslugu i tehničku podršku za svoju cjelokupnu liniju proizvoda. Duzine tehničke podrške s visokom stručnošću stacionirane su diljem svijeta kako bi pružile:

- Stručno savjetovanje

- Prilagođena rješenja

- Dijagnostiku i otklanjanje problema na licu mjesta

- Popravak i održavanje pretvarača

- Usluge instalacije

- Obuku operatera za opremu

- Popravak sustava, zamjenske dijelove, preventivno održavanje i još mnogo toga

Klijenti diljem svijeta oslanjaju se na Dynisco zbog inovacija proizvoda i naprednih sustavnih rješenja koja značajno utječu na učinkovitost njihovog proizvodnog procesa.

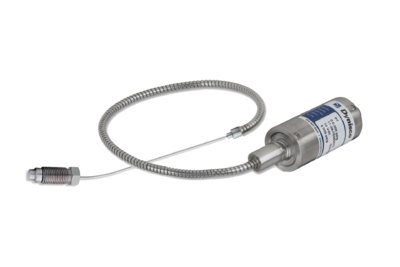

MDA 467

MDA 467 - Sensor with flexible and exposed capillary

The sensors of this 467 series have a flexible capillary with an exposed mounting tip, which is used in an area where it is not possible to install a standard sensor with a flexible capillary and a rigid stem. Individual models have different accuracy. Model 467 has an accuracy of 1.00% of the pressure range. Power supply with 10-12 V DC and membrane made of 15-5 PH material and coated with DyMAX layer. The length of the flexible capillary can be optionally configured.

Output signal 3.33 mV/V

Accuracy better than 1.00%

Power supply 10-12 Vdc

6 Pin connector

Shunt calibration

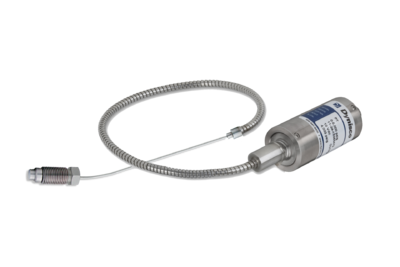

MDA 435

MDA 435 - Sensor with flexible and exposed capillary

The sensors of this series 435 have a flexible capillary with an exposed mounting tip, which is used in an area where it is not possible to install a standard sensor with a flexible capillary and a rigid stem. Individual models have different accuracy. Model 435 has an accuracy of 0.50% of the pressure range. Power supply with 10-12 V DC and membrane made of 15-5 PH material and coated with DyMAX layer. The length of the flexible capillary can be optionally configured.

Output signal 3.33 mV/V

Accuracy better than 0.50%

Power supply 10-12 Vdc

6 Pin connector

Shunt calibration

ECHO Series

ECHO sensors are a low-cost solution for common applications.

Power supply according to configuration as well as output signal (mV / V - mA - Vdc). Membrane made of 17-4 PH SST material.

Signál dle konfigurace

6 Pin konektor

±0,50% přesnost snímání

Shunt kalibrace

Vertex Series

Vertex is more accurate than any other mercury-filled sensor and is ideal for industrial applications that require low pressure.

The pressure range for Vertex is now available from 250 - 10,000 PSI. Not only is this an overall improvement to one’s process, but it helps with customers that are focused on sustainability and zero-waste.

Optional output signal

Mercury-free sensor

Reinforced membrane

Optional HART communication

Optional connector

Accuracy better than 0.25%

Internal Shunt Calibration (R-Cal)

Temperature Controller 1498 Series

The 1498 series temperature controllers represent an economical solution for precise temperature control of the machine. Thanks to its DIN size and several output configurations, the controller is suitable for twin and single screw extruders, both for screw temperature zones and for adapter zones, together with heating / cooling for individual zones.

Snadná konfigurace

Jednoduchá obsluha

Řízení teploty

Regulaci topení

Regulace chlazení

Indikace

Univerzální vstup

Opakované procesy

Rozměr 1/8 DIN

Modbus RS485

Temperature Controller 1496 Series

The 1496 series temperature controllers represent an economical solution for precise temperature control of the machine. Thanks to its DIN size and several output configurations, the controller is suitable for twin and single screw extruders, both for screw temperature zones and for adapter zones, together with heating / cooling for individual zones.

Easy configuration

Easy operation

Temperature control

Heating regulation

Cooling control

Indication

Universal entrance

Repeated processes

Size 1/16 DIN

Modbus RS485

ATC990 Process Controller

The ATC 990 series controller is a time-tested product that has received a new design and new functions. Compared to classic features such as pressure, temperature and alarm setting options, these new models are enhanced with the ability to monitor and record parameters to a USB drive, the undeniable advantage is the large display and interactive environment when setting up the controller.

Automatic tuning

Graphic / text LCD

Alarm color LED

Easy configuration

One loop control

USB port

Modbus RS-485

Modbus TCP Ethernet

Blue Control software

PG4 Series

Dynisco's series of mechanical pressure indicators is the ideal choice for applications that require simple and maintenance-free pressure indication.

Direct, local measurement

Mechanical construction

Optional flexible capillary

The indicator head is rotatable by 300°

Pressure range 5000 or 10,000 psi

Stainless steel construction

Melt Monitor Series

The Dynisco Melt Monitor alarm series is a melt pressure sensor with an integrated digital display. Optional temperature measurement is also available.

Double five-digit display

Peak function and digital zero calibration

Accuracy ± 1.0%

Optional units

Displays pressure and optionally temperature

Optional process connection

UPR 900 Panel Indicator

The Dynisco UPR900 is a compact 1/4 DIN process indicator. The UPR900 can display your preferred production process values. Optional secondary input for displaying the temperature or pressure of the polymer melt all in one place. The secondary input can be a strain gauge to measure the differential pressure in the process. The UPR900 contains two standard assigned alarms with the option to add a third alarm.

Display of pressure, temperature

both values including the difference

Optional second input

Analog retransmission

Local or remote configuration

Graphic / text LCD

LED indication and backlight

1490 Panel Indicator

Indicator 1490 is a universal device with one or two configurable alarms, optional linear process variable retransmission, optional pressure sensor power supply, and optional Modbus communication.

Universal input

2 alarm outputs

Optional signal retransmission

Min. / max. values

Optional com. Modbus

Optional 24VDC power supply

MDA 460 | 462 | TDA 463

MDA 460 - Sensor with rigid stem

MDA 462 - Sensor with rigid stem and flexible stem

TDA 463 - Combined sensor with rigid stem, flexible stem and built-in temperature sensor

The sensors of this 46X series are specific with a 6-pin bayonet connector and an accuracy of 1.00% of the pressure range. Power supply via 10-12 V DC. Membrane made of 15-5 PH material and coated with the DyMAX layer. The length of the rigid stem and the flexible capillary can be optionally configured.

Output signal 3.33 mV/V

Accuracy better than 1.0%

Power supply 10-12 Vdc

6 Pin connector

Shunt calibration