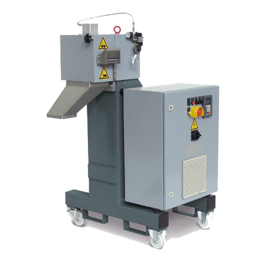

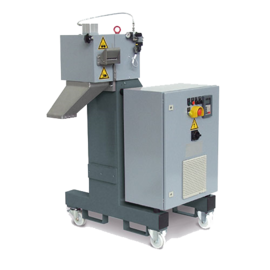

Bullet Series Strand Pelletizer

Pelletizer for dry cutting of strands for premixes, mixtures and extrusions

The Bullet series was created to combine the cutting geometry of the Conair 304 with the innovative features of the Scheer "E-Series" pelletizer. The combination of two market leaders in the basic design results in a spring dry cut pelletizer that is easier and faster to clean and repair.

Conair design and Scheer technology

Easy operation

Short cleaning time

Small dimensions

Recessed electrical panel

Push-Pull knives

Lower feeder with self-tensioning

Optional dual drive

Optional tungsten carbide rotor

PRIMO 100/200 E

Strand pelletizing systems for utmost flexibility during production

The dry cut strand pelletizers of the PRIMO E series are characterized by maximum flexibility. Variable system configurations allow for optimal matching with your specific production requirements and also provide utmost flexibility in terms of product changeover. The cylindrical pellets convince with their consistently high quality and are idealy suitable for further processing.

Compact dimensions

Quick tool change

Suitable for soft, brittle and abrasive polymers

Dual Drive

Easy access for cleaning

Upper feed roller

BAOLI

Dry cut pelletizing and strand pelletizing for compounding and recycling processing

Supported by bearings on both sides, the BAOLI dry-cut strand pelletizer for strand pelletizing and dry cut pelletizing produces cylindrical pellets of excellent quality ideally suited for further processing. BAOLI offers three machine sizes with working widths of 100 mm,

Cutting rotor supported by bearings on both sides

Maintenance-friendly – easy to clean

User-friendly

Reliable

Economic to run and cost-effective

BAOLI S

Strand pelletizing for dry cut processing

Successfully applied by hundreds of customers in China and abroad, the proven BAOLI strand pelletizers produce the highest quality of cylindrical pellets or micro pellets, ideally suited for further dry cut processing. BAOLI is specifically used for strand pelletizing of compounds, blends, and masterbatches.

Profi table production due to very high machine availability with wear-resistant cutting tools

Simple, efficient cleaning and maintenance as well as fast product changeover

Consistently high pellet quality

Highest reliability due to very long life time based on enhanced quality of all pelletizer components

More than 60 years of expertise in strand pelletizing and comprehensive service

Dry Cut “WD” Series

Underwater and dry cut pelletizing system – Dry Cut “WD” Series

The Dry Cut “WD” Series Waterslide pelletizing systems and dry cut strand pelletizing system have been developed to allow for a wide variety of materials to be run with little or no operator assistance. Strand conditioned water is used to improve pellet quality.

Increased production

More compact dimensions

High Quality

Long life

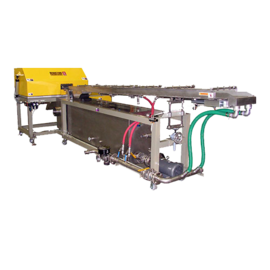

EBG Belt Conveyor Pelletizing System

Dry cut pelletizing and strand pelletizing system - EBG Belt Conveyor Pelletizing System

The belt conveyor pelletizing system EBG is specifically designed for the compounding of water-sensitive or highly filled (> 60 %) or fragile products in strand pelletizing and dry cut pelletizing. Variable system configuration permit a perfect adaptation to the product to be processed. Using the belt conveyor, even elastic and very flexible polymers may be handled easily and efficiently.

Wide processing window

Retro-fitting to existing pelletizing lines possible

Due to linear pelletizer feed, no strand breaks

Very slow drawing speed possible, starting at 8 m /min – Strand cooling by air, water, or both

Processing belt adaptable to different pelletizing heights

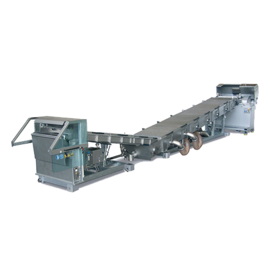

JSG

Automatic dry cut strand pelletizing system and dry cut belt conveyor pelletizing system – JSG

The proven JSG strand pelletizing systems are designed to achieve highest throughput rates in plastics compounding. The JSG systems produce cylindrical pellets of perfect quality for automatic dry cut strand pelletizing systems and dry cut belt conveyor pelleitizing systems, ideally suitable for further processing. Variable system configurations allow for optimal adaptation to the material to be processed.

Stability of the production process

Minimum residual humidity

Outputs up to 9,000 kg / h

Excellent quality of pellets

Perfectly customizable

Very long service life

Low demands on employees

M-ASG

Dry cut pelletizing and strand pelletizing for further processing – M-ASG

The proven WSG dry-cut pelletizing and strand pelletizing systems with M-ASG pelletizers produce top-quality cylindrical pellets that are ideal for further processing.

Robust double-sided bearing

Changes in the length and weight of pellets

Dual Drive

It handles high temperatures

Integration into the JSG system

Very long service life

PRIMO 60/120 E

Dry cut pelletizing systems for utmost flexibility during production – PRIMO E

Successfully applied by hundreds of customers, the proven WSG dry-cut strand pelletizing systems with PRIMO E pelletizers produce the highest quality of cylindrical pellets or microgranular compounds that are ideal for further processing for strand pelletizing and dry cut pelletizing systems. Variable system configurations allow for optimal matching with your specific production requirements and also provide utmost flexibility for product changeovers.

Compact size

Stable quality of pellets

Quick tool change

Suitable for soft, brittle and abrasive polymers

Dual Drive function

Easy access for cleaning

S3500 Series

Strand pelletizing and dry cut pelletizing for polymer manufacturing – S3500 Series

The S3500 Series Strand Pelletizer has been engineered to provide easy, tool-less entry into the stainless steel cutting chamber for strand pelletizing and dry cut pelletizing. The “Slide” Series pelletizers are designed to substantially reduce maintenance and cleaning time for polymer manufacturers. The front section of these plastic pelletizers is mounted on a linear slide mechanism allowing access into the cutting chamber. Maintenance and cleaning of the feedrolls, doctor blade, and bed knife are quick and easy.

Unique Rotor Design for Maximum throughputs

Wide Feed Entrance

Insulated sound hood optional

Stainless Steel contact areas

Tool-less entry

Air Actuated Upper Feedroll

Dual drive optional

Designed per customer application

SGS 100/200/300-E6

Strand pelletizer for strand pelletizing and dry cut pelletizing for compound production

More than thousand machines in operation: The cantilvered pelletizers of the SGS-E series demonstrate their quality under the toughest production conditions for strand pelletizing and dry cut pelletizing — since the beginning of the 1980s. A sturdy and sophisticated design as well as many technical details for improved accessibility when cleaning and/or changing products reduce unproductive downtime and make the SGS-E the preferred pelletizer for production of masterbatches and small lots. The improved cutting geometry extends the production range especially when processing soft, elastic, and very brittle materials.

Compact and economical

Improved cleanability

Large range of processing

SGS 200-L / SGS 300-L / SGS 400-L

Strand pelletizer for strand pelletizing and dry cut pelletizing for the production of thermopalstic pellets

The strand pelletizers of the SGS series are used for the production of thermoplastic pellets for strand pelletizing and dry cut pelletizing. In order to withstand everyday production conditions, the technology of a pelletizer must be extremely robust, which is

Short change-over time

Easy handling

High machine availability

Favourable alternative compared with a spare cutter