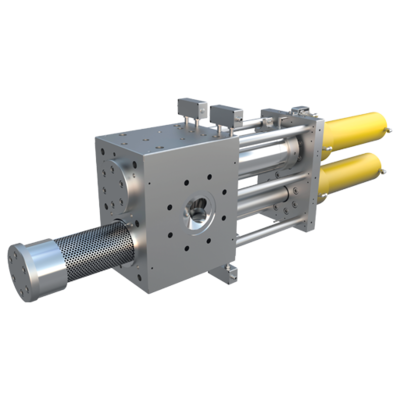

CSC-R

Large-area screen changers from MAAG are based on the sturdy and proven double-piston screen changer design. The patent-registered curved screen plate provides four times more active screen area than a conventional screen changer with circular screen cavities. The highly compact size permits higher throughput rates and filtration grades, as well as reducing pressure loss and multiplies the screen life time in the filtration systems. The simple and robust design, with no additional sealing elements, ensures reliable and leak-age-free continuous operation.

TECHNICAL DATA

| Throughput rate [kg/h] | 1900 – 52200 | |

| Operation method | kontinuierlich | |

| Required heating output [kw] | 1,6 – 80 o.1,6 – 112 | |

| Additional designs |

Diverter Valve

|

|

| Filter surface [cm²] | 2x 4747 | |

| Number of sieve cavities | 2 | |

| Screen diameter/length | 96 mm to 560 mm | |

| Filtration area | 2 x 172 cm2 to 2 x 4747 cm2 | |

| Mounting | Compact size, any installation position possible | |

| Technology | Sturdy and proven double-piston configuration requiring no additional seal |

APPLICATION FIELDS

|

Flat films

|

|

|

Foam films

|

|

|

Blown films

|

|

| Plates | |

| Pipes | |

| Profiles | |

| Blow mouldings | |

| Fibres | |

| Pelletization | |

| Recycling | |

| Compounding |

OPTIONS

|

Electric, liquid, or steam heating

|

|

|

High-pressure version

|

|

|

High-temperature version

|

|

| Coated flow channels | |

| Stainless steel design | |

| High-pressure breaker plate |

ACCESSORIES

|

Filter screens

|

|

|

Adapters

|

|

|

Support frames

|

|

| Controls | |

| Breaker plates | |

| Safety guards |