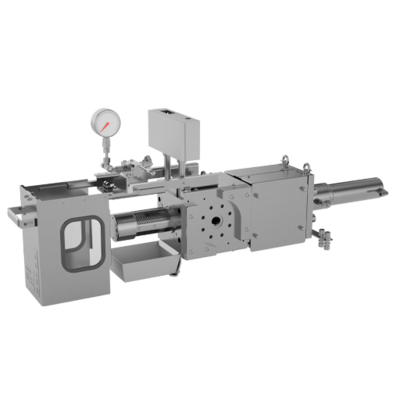

DSC

The discontinuously operating single piston screen changer, equipped with a screen cavity, offers a robust and economic alternative for extrusion and compounding applications which permit a brief interruption in the melt flow when changing the screen. Thus, it is also ideal for batch applications. After a batch is complete, a screen change can be made during an application-related shut-down of the unit.

TECHNICAL DATA

| Throughput rate [kg/h] | 40 – 6900 | |

| Operation method | kontinuierlich | |

| Required heating output [kw] | 2,52 – 72 | |

| Additional designs |

Candle filters |

|

| Filter surface [cm²] | 1256 | |

| Number of sieve cavities | 1 | |

| Screen diameter/length | 30 to 400 mm | |

| Filtration area | 7 to 1,256 cm2 | |

| Mounting | Compact mounting dimensions, all positions possible | |

| Technology | Proven single-piston design, which goes without additional seals |

APPLICATION FIELDS

|

Flat films

|

|

|

Foam films

|

|

|

Blown films

|

|

| Plates | |

| Pipes | |

| Profiles | |

| Blown mouldings | |

| Fibres | |

| Granulation | |

| Compounding |

OPTIONS

|

Oil, liquid, or steam-heated

|

|

|

High pressure breaker plate

|

|

|

High-temperature version

|

|

| Coated flow channels | |

| Stainless steel design | |

| With venting function |

ACCESSORIES

|

Connection adapters

|

|

|

Support carriages

|

|

|

Breaker Plates

|

|

| Protective devices | |

| Maax® BF control system |