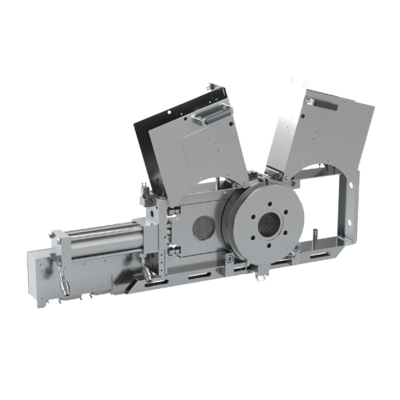

FSC

FSC hydraulic screen changers from MAAG are equipped with a pressure-adaptive sealing system as a standard for filtration systems. Thanks to this sealing system, the required sealing forces are automatically adjusted by the screen changer to the actual melt pressure. The narrow design is especially suited for being used in applications with thermally sensitive materials. Their solid and robust construction, available in all sizes and designs, ensures reliable and leak-free filtration systems of molten polymers for many years. The hydraulically operated screen changer reliably guarantees the protection of melt pumps and fine mold gaps from damage and soiling.

TECHNICAL DATA

| Throughput rate [kg/h] | 90 – 3900 | |

| Operation method | kontinuierlich | |

| Required heating output [kw] | 2,9 – 32,8 | |

| Additional designs |

Diverter Valve

|

|

| Filter surface [cm²] | 16 – 1590 | |

| Number of sieve cavities | 2 | |

| Screen diameter/length | 45 to 300 mm | |

| Filtration area | 16 cm2 to 707 cm2 | |

| Mounting | Compact mounting dimensions, all positions possible |

APPLICATION FIELDS

|

Flat films

|

|

|

Foam films

|

|

|

Blown films

|

|

| Plates | |

| Pipes | |

| Profiles | |

| Blown mouldings | |

| Fibres | |

| Granulation | |

| Compounding | |

| Recycling |

OPTIONS

|

PVC design

|

|

|

Coated flow channels

|

|

|

Stainless steel construction

|

|

| High-pressure breaker plate |

ACCESSORIES

|

Connection adapters

|

|

|

Support carriages

|

|

|

Breaker Plates

|

|

| Protective devices |