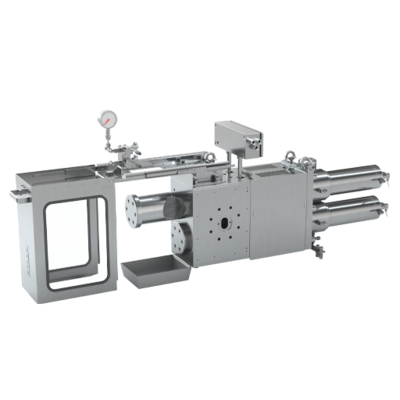

CSC

Continuous CSC screen changers from MAAG with their robust and leak-free operation meet highest quality standards with respect to melt filtration systems. Because of their constantly improved functionality, continuous screen changers from Maag increase product quality significantly. CSC screen changers are based on the proven double-piston screen changer design that operates without any additional seals. Their sturdy construction, available in all sizes and designs, guarantees the reliable and leak-free filtration of polymer melts for many years.

TECHNICAL DATA

| Throughput rate [kg/h] | 80 – 14000 | |

| Operation method | kontinuierlich | |

| Required heating output [kw] | 1,6 – 80 | |

| Additional designs |

Backflush option |

|

| Filter surface [cm²] | 14 – 2512 | |

| Number of sieve cavities | 2 | |

| Screen diameter/length | 30 mm to 400 mm | |

| Filtration area | 14 cm2 to 2,512 cm2 | |

| Mounting | Compact mounting dimensions, all positions possible | |

| Technology | Proven sealless double-piston desig |

APPLICATION FIELDS

|

Flat films

|

|

|

Foam films

|

|

|

Blown films

|

|

| Plates (Sheet) | |

| Pipes | |

| Profiles | |

| Blow mouldings | |

| Fibres | |

| Granulation | |

| Recycling | |

| Compounding |

OPTIONS

|

Electric, liquid or steam-heated

|

|

|

High-pressure version

|

|

|

High-temperature version

|

|

| Coated flow channels | |

| Stainless steel design | |

| High-pressure breaker plate |

ACCESSORIES

|

Connection adapters

|

|

|

Support carriages

|

|

|

Control systems

|

|

| Breaker Plates | |

| Protective devices |