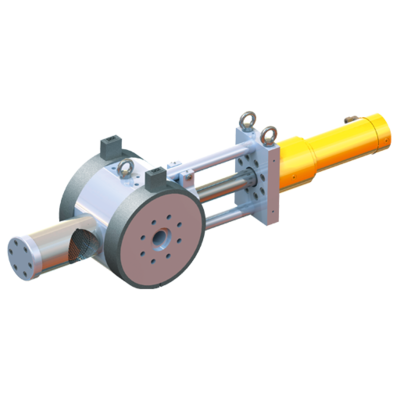

SSC

The compact single-piston screen changers SSC from MAAG provide a cost-effective filtration alternative for extrusion applications which allow for interruptions in the melt stream during screen changeovers. SSC operate without any additional seal. Their sturdy construction guarantees reliable and leak-free filtration of polymer melts. The rheologically optimized flow channel directs the melt flow optimally and with a short residence time into the screen cavity. The breaker plate is fitted with screen mesh suitable for the required filtration size. The screen changer is operated by a hydraulic piston.

TECHNICAL DATA

| Throughput rate [kg/h] | 40 – 1700 | |

| Operation method | diskontinuierlich | |

| Required heating output [kw] | 1,7 – 7,2 | |

| Additional designs |

Candle filter elements |

|

| Filter surface [cm²] | 7 – 314 | |

| Number of sieve cavities | 1 | |

| Screen diameter/length | 30 mm to 200 mm | |

| Filtration area | 7 cm2 to 314 cm2 | |

| Mounting | Compact mounting dimensions, all positions possible | |

| Technology | Proven sealless single-piston desig |

APPLICATION FIELDS

|

Flat films

|

|

|

Foam films

|

|

|

Blown films

|

|

| Plates | |

| Pipes | |

| Profiles | |

| Blown mouldings | |

| Fibres | |

| Granulation | |

| Compounding |

OPTIONS

|

Choated flow channels

|

|

|

Stainless steel design

|

ACCESSORIES

|

Connection adapter

|

|

|

Support carriages

|

|

|

Control systems

|

|

| Breaker Plates | |

| Protective devices |