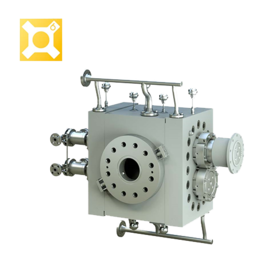

Polyrex⁶ PR

Processes in the manufacture of polyolefins like polyethylene and polypropylene require high-pressure gear pumps which build up pressure for the units after the compounder, meaning for extrusion and pelletizing. The new performance-driven geometry of the x6 class of polyrex® results in high throughput rates at high flow rates and low shear stress. Polyrex⁶ can convey low viscosity polymers where earlier polymer metering pump generations failed. The increased pump performance during polymer processing makes the specific conveying capacity 50% higher compared to same housing size pumps of older generations. For debottlenecking existing plants, MAAG offers alternative housing designs with matching interfaces to older polymer metering pump generations.

TECHNICAL DATA

| Rotational speed [U/Min] | max. 85 | |

| Torque [Nm] | max. 1625000 | |

| Differential pressure [bar] | max. 320 | |

| Viscosity [MPas] | 20000 Pas | |

| Temperature [°C] | max. 350 | |

| Throughput rate [kg/h] | max. 120 | |

| Pump size | 3 – 100 | |

| Output [l/Min] | max. 1650 |

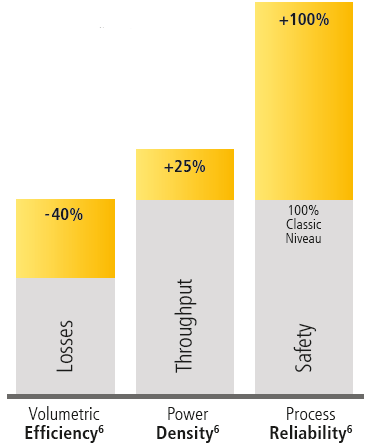

Volumetric Efficiency6

Instant Flexibility Reduced back-flow to offer you the choice between higher differential pressure or boosted throughput rate

Flow Economy Reduced back-flow to lower your energy consumption

Power Density6

Compacted Power Performance driven geometry to reduce your total cost of ownership

Process Reliability6

Smart Flow Fast lubrication replacement to improve your process stability