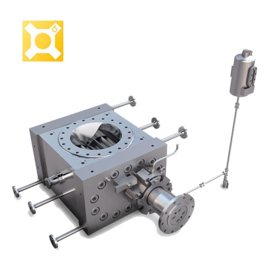

Vacorex⁶ VX

MAAG introduces the vacorex® x6 class polymer extraction gear pump. vacorex⁶ ideally fulfills modern polymer production processes which require polymer pumps that can discharge at high pressure despite very low fill level and high vacuum conditions in the reactor/devolatilization vessel.

MAAG vacorex⁶ polymer extraction pumps process a wide range of different polymer grades without affecting their quality. Reliable, requiring little maintenance, and robust enough to withstand the rigors of years of operation, the vacorex⁶ polymer gear pump is the ideal solution for such applications.

extrusion lines.

TECHNICAL DATA

| Rotational speed [U/Min] | max. 150 | |

| Differential pressure [bar] | – 320 | |

| Viscosity [MPas] | max. 20000 | |

| Temperature [°C] | max. 350 | |

| Throughput rate [kg/h] | max. 170 t/h | |

| Pump size | 100 – 560 | |

| Output [l/Min] | max. 2700 | |

| Housing | Alloy-/Carbon Steel -other material on request | |

| Gear shafts | Nitrided steel / tool steel | |

| Bearing | Tool steel / ALBr / special materials | |

| Shaft seal |

Standard: vispac® with standard barrier system and adjustable throttle screw

|

|

| Connections | ANSI or DIN standards | |

| Pump heating | Thermal oil or steam; design condition 25 bar / 350°C | |

| Installation | The vacorex® gear pump can be flanged directly under the reactor | |

| Suction side | Inlet pressure: up to 10 bar |

SELECTION OF TYPICAL PUMPED MEDIA

|

PET / PBT

|

|

|

Polyamide, Polycarbonate

|

|

|

Cellulose acetate, Polyacrylicnitrile

|

|

| Silicone / Oil additives | |

| SBR Latex / Epoxy resin | |

| Phenolic resin, Polymethylmethacrylate | |

| Polystyrene (incl. ABS, EPS) | |

| Polysulphone | |

| Elastomers / Polyolefine | |

| And others | |

| Paints and varnishes | |

| Waxes and paraffins | |

| Mineral oils and fats | |

| Fuels | |

| Petrochemical products | |

| Lube oil |

ACCESSORIES

|

High-precision monitoring systems for pressure and temperature

|