- Elastomer Extrusion Pumps

- Chemical & Industrial Pumps

- Polymer Production Pumps

- Thermoplast Extrusion Pumps

Dosing pumps for polymer systems

For more than 100 years, MAAG has been developing and manufacturing pumps at its headquarters in Switzerland. MAAG is proud of its core competence - the development and production of gear pumps for polymers, chemicals and lubricants and filtration systems for the production and processing of plastics. Today, MAAG is one of the world's leading manufacturers of elastomeric extrusion pumps, thermoplastics, extrusion pumps, industrial pumps, chemical pumps and melt pumps for polymer production. Thanks to many years of experience with production and a deep understanding of polymer production and processing processes, gear pumps of all types can be optimally adapted to individual customer requirements. Technical know-how and the ability to respond to specific customer requirements make it possible to achieve the highest possible efficiency for a given industrial process. The maximum service life of MAAG pumps and melting pumps and the minimum downtime are a great guarantee of the successful operation of industrial plants.

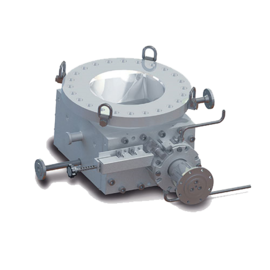

Viscorex® VR

Polymer extraction and transfer pump for polymer applications

Polymer processes in the polymer industry require units that gently discharge low and high-viscosity plastic melts from reactors and degassing equipment. The MAAG polymer extraction pump systems and viscorex® transfer gear pumps feature the excellent fill behaviour and short residence times that make them the ideal solution for such polymer applications. Their high efficiency and long service life will enhance the capacity and availability of your polymer production line. viscorex® transfer gear pumps efficiently convey plastic melts with a constant, precise flow.

Gentle treatment of polymer melts thanks to special gear teeth with low squeezing power

Excellent fill behaviour due to optimized inlet geometries

Optimized flow channels

High overall efficiency and hence minimized friction thanks to pioneering gear and bearing technology

Low pulsation pumping even at high differential pressures

Compact design