Melt Flow Indexer LMI 4000 Series

For over 25 years the Dynisco Polymer Test has taken

a leading role in working with the polymer process-ing industry to develop advanced polymer melt testing instrumentation for quality control and research applications. This extensive experience, combined with advances in electronics technology, has resulted in the new LMI 4000 melt flow indexers.

Four melt flow indexer models are offered in the advanced Dynisco Polymer Test LMI 4000 series, each with features designed to meet specific application requirements:

Display and Programming Made Easy

• A 4-line by 20-character vacuum fluorescent display allows users to read detailed information about test conditions.

• A 4-line by 20-character vacuum fluorescent display allows users to read detailed information about test conditions.

• For international use, the display operates in English, German, French, Spanish and Czech.

• Smart keys located directly under the display allow operators to quickly program the LMI 4000 by accessing menus of the most common test conditions.

• For special tests, custom programs can be entered using the membrane keypad, with models D4003 and D4004 able to recall up to 60 sets of test conditions from memory.

Maximum Accuracy for Method “B” Tests

• The digital encoder option, D4059, is the most accurate method available to measure piston displacement and rate of descent during test method “B.”

• The digital encoder option, D4059, is the most accurate method available to measure piston displacement and rate of descent during test method “B.”

• Accurate to within 0.025mm over the full 25.4mm test travel length.

• Allows up to fifteen discrete melt index values to be collected per test, with each discrete melt index value reported or the average melt index.

• Available on D4002, D4003 and D4004 models.

• In addition, the LMI 4000 with D4059 can monitor the piston’s rate of descent and automatically select the correct flag length for that test.

Windows™ Software Enhances Database

• Operating in the popular Windows™ environment on standard personal computers, Dynisco Polymer Test’s MIWORKS for Windows™ acts as a melt index test database.

• The software downloads test parameters directly to the melt indexer and enables control charts to be created and data exported to spreadsheets.

• Up to eight model D4004 units can be connected to a single personal computer when using the optional multiplexing system.

• MIWORKS for Windows™ software is provided with each model D4004 melt indexer.

Comprehensive Reporting Capabilities

• By simply connecting model D4003 or D4004 to a standard printer, comprehensive reports about the melt index test are quickly generated by the instrument’s internal computer.

• Intrinsic Viscosity of PET correlation values are reported with Models D4003 and D4004. In addi-tion to information about test conditions, values for melt index, shear stress, viscosity and appar-ent melt density are reported.

• The LMI 4000 calculates the average, standard deviation and coefficient of variance for both the melt index and viscosity values when performing multiple tests of the same material.

Options for Special test requirements

• Pneumatic or electric weight lowering and raising systems are offered for use with heavy loads or for more automatic operation of the melt index test.

• Pneumatic or electric weight lowering and raising systems are offered for use with heavy loads or for more automatic operation of the melt index test.

• The lifts allow flow rate ratio and other multiple load tests to be conducted safely, and is avail-able on all models except the basic D4001.

• Lift weights are an innovative design that “stack” for improved ergonomics, to meet all ASTM D1238 melt conditions, and to allow for weight interchangeability.

• An alloy barrel is available for testing PVC and other corrosive materials.

• For installations performing frequent melt index tests or where hard-to-clean engineering poly-mers are being tested, the optional high-speed barrel bore power cleaning kit is a must.

• An automatic cut-off device can improve precision of method “A” tests.

• Available on all models, the auto cutoff device can be programmed to make cuts at fixed intervals after “melt time” is completed.

• Performance that meets international standards

• Stackable weight options that are both user and ASTM D1238 standards friendly

• Self-diagnostics capability

• Comprehensive statistical capability

• Simple push-button RTD calibration

• Smart keys for easy programming

• Bright, 4-line by 20-character vacuum fluorescent display

• Windows™ software for test database and analysis

Provided results

| Melt flow index: | MFR - Melt Flow Rate [g/10min] |

|---|---|

| Melt flow index: | MVR - Melt Volume Rate [ccm/10min] |

| Melt density: | MD - Melt Density [g/ccm] |

| Intrinsic viscosity (PET): | IV - Instristic viscosity [dl/g] |

| Shear Viscosity: | Shear Viscosity [Pa.s] |

| Shear rate: | Shear Rate [1/s] |

Performance parameters

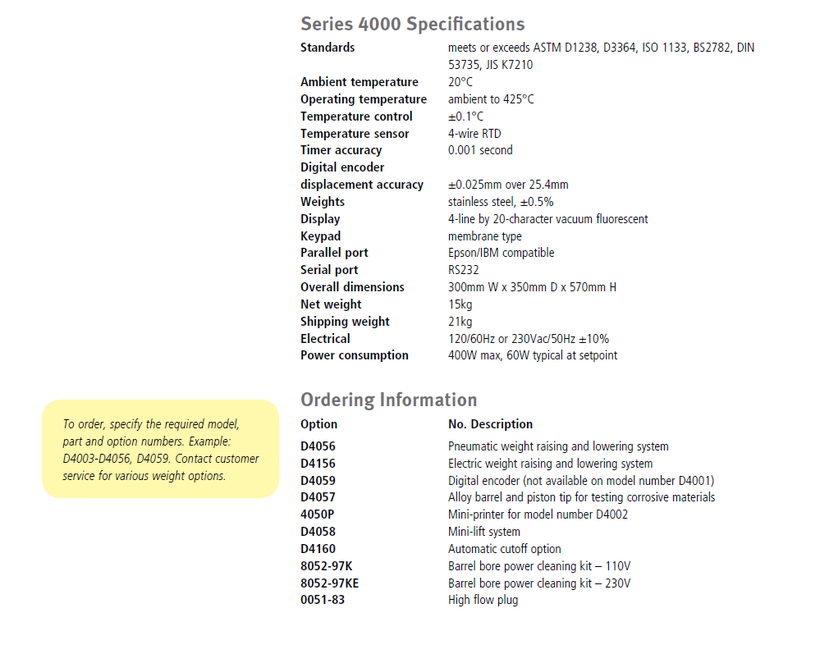

| Meets standards: | ISO1133-1, ASTM D1238 & D3364, BS2782, DIN 53735, JIS K7210 |

|---|---|

| Operating temperature: | Max. 425°C |

| Temperature control accuracy: | ±0.10°C |

| Timer accuracy: | 0.001 s |

| Accuracy of digital encoder: | ±0.025mm over 25.4mm |

| Display: | 4-line by 20-character vacuum fluorescent |

| Keypad: | Membrane type |

| Weights: | Weights stainless steel, ±0.5% |

| Communication: |

RS232 - Parallel port Epson/IBM compatible

|

| Dynisco Cloud: | YES |

| Dynisco Service Care: | YES |

Other parameters

| Overall Dimensions, Base Model: | 300mm W x 350mm D x 570mm H |

|---|---|

| Weight, Base Model: | 15kg |

| Shipping Weight, Base Model with Weights: | 21kg |

| System Voltage: | 120/60Hz or 230Vac/50Hz ±10% |

| Power: | 400W max, 60W typical at setpoint |