CMR IV - Rheometer

Specifically designed for the thermoplastics resin industry, the Dynisco CMR series can be configured to measure melt flow rate, high/low load melt flow rate, apparent viscosities, or to perform other customer defined tests.The CMR system consists of two parts: a rheometer head connected directly to the process which samples, conditions, and measures the melt flow of the resin, and an RCU (Rheometer Control Unit) that controls the CMR test parameters (temperature, pressure, rate), and provides outputs of computed results, and communications to an external distributed control system when required.

Features:

• On-line melt flow rate correlated to ASTM D1238

• On-line apparent viscosities

• Data exchange by analog and digital input/outputs

• Customer specified solutions

• Systems for hazardous locations

• Compact measuring head for close extruder connection

• Dynisco Vertex® Mercury Free Pressure Transducers forhigh accuracy

• A range of metering pump sizes for specific applications

• Simple ”in the field“ calibration

• Alarm system for malfunctions

• Rugged industrial designDynisco

Online Rheological Measurement Experience the Benefits of Online Rheology Measurement

CMR IV

The rheometer samples molten polymer from the process through a heated transfer line. A metering pump then drives the polymer melt through a capillary die of accurate diameter and L/D ratio, at a precisely controlled rate. The pressure drop across the die is measured by a Vertex Mercury Free pressure transducer. When the system is run at constant pressure (shear stress) and the flow rate is determined, a continuous measurement of the MFR is obtained. A wide range of accurate inter-changeable capillaries provide the system with high resolution and a broad range of capabilities.

CMR IV - RCU: ULTIMATE PERFORMANCE

Our high performance RCU combines the rheological properties of a Laboratory Capillary Rheometer with MFI readings delivered by a Melt Flow Indexer. It has been updated with a Siemens S7-1500 PLC with a Siemens

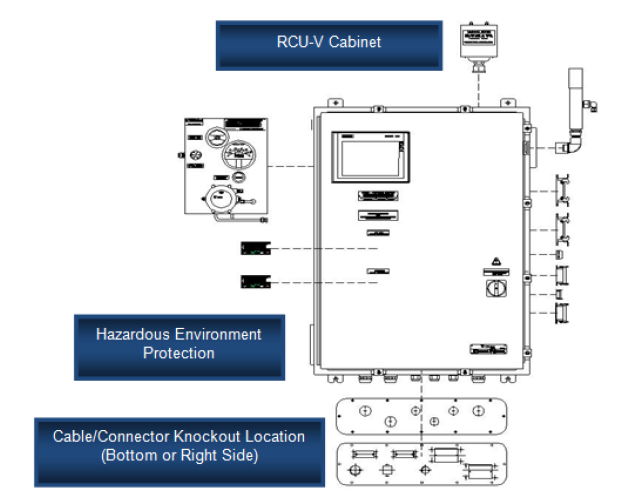

Our high performance RCU combines the rheological properties of a Laboratory Capillary Rheometer with MFI readings delivered by a Melt Flow Indexer. It has been updated with a Siemens S7-1500 PLC with a Siemens 7” (178mm), Comfort Panel Touch Screen HMI. This combi-nation provides increased processing power and hi-end graphics enabling the RCU to provide +/- .5% Full Scale Accuracy. This allows the RCU to better align measure-ments with those taken from laboratory instruments. Furthermore, it is certified for hazardous environments as needed. The RCU will allow for up to 7 analog outputs and 8 digital outputs- see more information in specification chart

VISCOSENSOR e-RCU: PERFORMANCE SIMPLIFIED

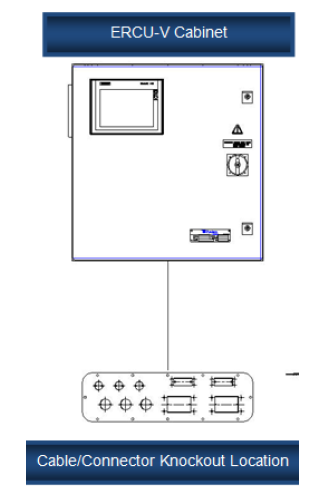

The CMR IV e-RCU offers a simplified PLC with the digital and analog I/O that most plants would need for

a cost effective approach to measuring online rheology. It has a Siemens S7-1200 PLC with a Siemens 7” (178mm) Comfort Panel Touch Screen HMI. This combination provides the system with processing power and hi-end graphics allowing the e-RCU to provide +/- 2% Full Scale Accuracy. The e-RCU provides the processor the ability to measure Melt Flow Ratio, Relative Viscosity, Intrinsic Viscosity, and Melt Viscosity in typical end-user environ-ments. All of which create a cost-effective system that reduces the risk of failure to an acceptable level. If con-ditions change and the system is needed in a hazardous and/or classified location, compatibility with the standard RCU allows for an easy upgrade. The e-RCU will allow for up to 2 analog outputs and 2 digital outputs- see more information in specification chart

Experience the Benefits of Online Rheology Measurement

PERFORMANCE CHARACTERISTICS

| Melt Flow Index | 0.02 - 5000 g/10 min |

|---|---|

| Viscosity Range | 10 - 105 Pa.S |

| Shear Stress | 150 - 1.5 x 105 Pa |

| Shear Rate | 1 do 7500 sek-1 (matryca standardowa) Maksymalnie 50 000 (matryca specjalna) |

Dies |

|

| Viscosity | 1 - 5mm, 10 do 30:1 L/D |

| Melt Flow Index | 3.8182:1 L/D |

| Special Dies | Na życzenie |

| Pressure Range | 3 x 105 – 3.5 x 107 Pa |

| Metering Pump | 0,16 cm3 / RPM (standard) 0.297 cm3/obr/min (opcja) 0.584 cm3/obr/min (opcja) |

| Pump Speed | 3 – 75 RPM |

| Polymer Flow | 225 g/h (średnio) |

MEASUREMENT AND CONTROL FUNCTIONS

Shear Stress Mode |

|

|---|---|

| Set point | Pressure |

| Measurement | Melt Flow Index |

Shear Rate Mode |

|

| Set point | Pump Speed |

| Measurement | Apparent Viscosity |

| Temperature Control | 3 Heating Zones |

ELECTRICAL SPECIFICATION

| System Voltage | 208-240 VAC, 1Ø, 50/60 Hz-standard |

|---|---|

| Power | 1200 W (max |

RHEOLOGIC CONTROL UNIT SPECIFICATIONS

RCU |

E-RCU |

|

| Electrical Cabinet | NEMA 4, 4x, 12 (IP66) | NEMA 4, (IP61) |

| CPU: | Siemens 1500 Series | Siemens 1200 Series |

| Operator Interface | HMI, Siemens Comfort Panel | HMI, Siemens Comfort Panel |

| Dimensions: | 45” H x 30”W x 13”L (1143 mm x 762 mm x 330 mm) |

24”H x 24”W x 10”D (609 mm x 609 mm x 254 mm) |

| Weight | 275 lbs | 80 lbs |

ANALOG OUTPUTS: (4 – 20 MA STANDARD)

| Select any 7 of the following: | Select any 2 of the following: | |

| Options | 1. Melt Flow Index ((MFI) in g/10 min 2. Motor Speed (RPM) 3. Capillary Zone Pressure 4. Pump Zone Pressure 5. Melt Temperature 6. Auxillary Temperature 7. Pressure 8. Shear Rate 9. Shear Stress 10. Melt Viscosity 11. Relative Viscosity 12. Intrinsic Viscosity 13. Configurable by User 14. Configurable by User |

1. Melt Flow Ratio 2. Melt Viscosity 3. Relative Viscosity 4. Intrinsic Viscosity |

DIGITAL INPUTS

| DIGITAL INPUTS | 24VDC, 9 mA |

|---|

DIGITAL OUTPUTS

| DIGITAL OUTPUTS | NC dry contacts -- 12 V min, 250 VAC max, 10 mA min, 6 A max, 20 W max |

|---|

System Diagrams RCU :

System Diagrams E-RCU:

Certification Approval

|

EU Declaration of Conformity |

|

ISO 9001:2015 |

|

EAC - The Eurasian Conformity mark |

|

RoHS Compliance Fact Sheet |