Providing Innovative Solutions

With more than 6 decades of commitment to helping customers, Dynisco provides the tools and services for the polymer industry allowing customers a “window into the process”.

Today’s customers require accurate information that will allow them to validate and if necessary adjust their process ensuring the products they make meet or exceed their specifications. The information Dynisco provides allows our customers to keep their process consistent regardless of their global locations.

Dynisco’s diverse portfolio of sensing and polymer test equipment delivers some of the most accurate information available in the market for the measurement of polymer rheology, pressure, and temperature.

Dynisco provides our customers the ability to correlate the data derived from pilot to laboratory environments with online production, 24 hours a day. This data allows for immediate response and adjustment to critical parameters ensuring any variations are promptly corrected to guarantee quality while maximizing their output.

Dynisco History

Known worldwide for leading-edge pressure and temperature measurement and control products for the plastics extrusion industry, Dynisco has been developing innovative, high-quality solutions for plastics extrusion processing for 60 years built on the expertise of an engineering staff that averages 15-20 years experience. Dynisco sensors, controls, and analytical instruments have proven to offer better control, reduced downtime, minimum scrap, and unmatched reliability and working life. Our dedication and ability to collaborate with you to help you measure, analyze and outfit extrusion control systems that fit your exact needs are unmatched. From breakthrough technology in the industry’s most complete line of sensors to renowned quality and performance in indicators, controls, and analytical instruments.

Dynisco Sensors Designed specifically for the rugged environment of the plastic industry, Dynisco has developed some of the most innovative measurement solutions for plastic extrusion, molding and process control applications. Manufacturing a wide range of robust mV/V, mA, VDC and HART-compatible melt pressure sensors, through engineering excellence built on expertise and experience.

Dynisco Analytical Instruments Process quality begins with the material being used. Dynisco's analytical instruments allow the processor to verify material specifications and optimize process conditions. These instruments include melt flow

[Dynisco Heilbronn Germany Facility]

indexers, capillary rheometers, and small laboratory mixing extrusion systems. Dynisco also offers the most comprehensive and accurate line of online rheometers available in the market today.

Dynisco offers a full range of global service and technical support for our complete line. Dozens of highly skilled, technical support personnel are stationed internationally to provide:

- Expert consultation

- Custom design solutions

- On-site equipment diagnostics and trouble-shooting

- Transducer repair and maintenance ∙ Installation services

- Operator training for equipment ∙

- System repairs, replacement parts, preventive maintenance and more

Customers around the world have come to depend on Dynisco for product innovation and advanced system solutions that have a significant impact on their manufacturing process efficiencies.

Six-core, shielded cable with threaded Bendix 6pin connector

These cables are used to connect Dynisco pressure sensors to a 6-pin connector. The cables provide the electrical connection between the sensors and the indicators or controllers. The kits consist of a Bendix bayonet connector and a six-core shielded cable.

Six-core cable

Shielded cable

Bayonet connector

6-Pin

Transducer Mounting Hole Machining Tool Kit

The Dynisco Transducer Mounting Hole Machining Tool Kit contains all of the necessary drills and taps to prepare a standard 1/2 - 20 UNF transducer mounting hole and the 45 degree seat. All tools included in this kit are made of premium grade, high strength tool steel. Care should be taken in the use of proper speeds and feeds, lubricants, and a method to assure continual alignment of each progressing tool. M10 and M18 kits are also available.

Thread repair

Prevents damage to the sensor

Maintenance prevention

Leak removal

Transducer Mounting Hole Cleaning Tool Kit

Installation of transducers into improperly cleaned or sized holes is one of the major causes of damage to these instruments. With this kit, the .312" tip diameter hole, the 45 degree seating surface, and the .451" hole can be cleaned. The kit includes a gauging plug which is used to verify that the hole has been correctly machined and cleaned. M10 and M18 cleaning kits also available.

Thread cleaning

Prevents damage to the sensor

Maintenance prevention

Melt removal

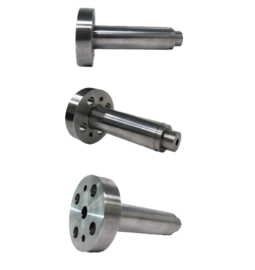

Adapters Button Seal

Process adapters are an accessory to all pressure and temperature sensors, allowing a 1 / 2-20 UNF (Unified National Fine nt) melt pressure sensor to be installed in the mounting port using a flange. The use of the flange is compatible with all sensors of the given dimensions and all manufacturers. Each adapter and sealing elements are made to order depending on the dimensions and mounting port. Flange extensions are available as one-piece constructions or detachable threaded connections. The design of the flange is specific to the one used and depends on the dimensions, thickness and diameter of the mounting screws.

Adaptation of any 1 / 2-20 UNF pressure sensor to the process flange adapter

Can be used with all Dynisco sensors

The flanges can be supplied in one piece, with a thread or a combination of thread and weld

Custom production

MDA 420 | 422 | TDA 432

MDA 420 - Sensor with rigid stem

MDA 422 - Sensor with rigid stem and flexible capillary

TDA 432 - Combined sensor with rigid stem, flexible capillary and built-in temperature sensor

The sensors of this 42x series are specific with an 6-pin threaded connector Bendix and an accuracy of 0.50% of the pressure range. Power supply via 10-12 V DC. Membrane made of 15-5 PH material and coated with DyMAX layer. The length of the fixed rod and the flexible capillary can be optionally configured.

Output signal 3.33 mV / V

Accuracy better than 0.50%

Power supply 10-12 Vdc

6 Pin connector

R-Cal calibration