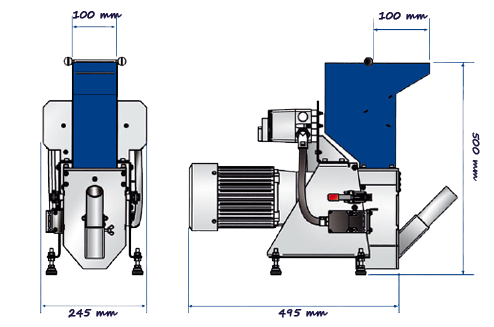

MiniGran - Laboratory Granulator

The Dynisco MiniGran Lab Granulator is designed for the granulation of small sprues. With its very compact dimensions, this granulator can be accommodated almost anywhere and therefore is very suitable for laboratory applications. The granulator is suitable for all kind of plastic materials, due to the low rotor speed the plastic materials are processed to high-quality, low-dust regrind. The cutting chamber of the MiniGran, including rotor and screen, are made of carbon steel, to fulfill high purity standards for regrind. In addition, the cutting chamber is hermetically sealed to prevent the regrind from being contaminated by incoming air or dust when extracted by suction. It is therefore possible to use this granulator under clean room conditions. The granulating chamber can be opened quickly and simply and can be cleaned rapidly, facilitating quick changes in materials or color. The optimized cutting geometry with a cascaded rotor in chevron design guarantees a very effective granulating process and also reduces the energy consumption.

| Openable cutting chamber: | 80 mm x 100 mm |

|---|---|

| Rotor diameter: | 90 mm |

| Rotor speed: | 112 U/min |

| Rotor blades: | 9 pcs. |

| Stator knives: | 2 pcs. |

| Engine power: | 0,75 kW |

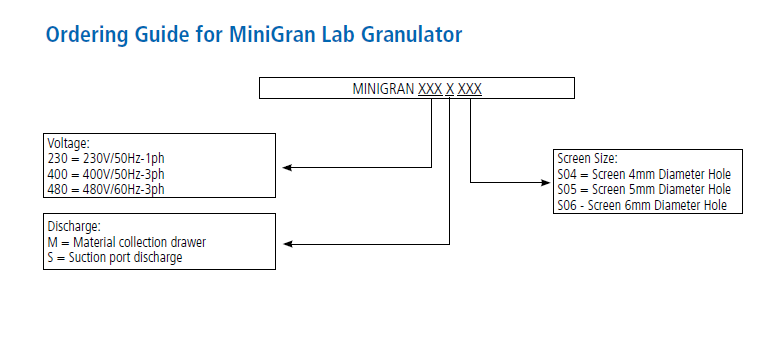

| Power supply: | 230, 400, or 480 V / 50 Hz |

| Screen hole size: | 3-5 mm |

| Screen: | With 4 mm holes as standard, alter. 3 and 5 mm holes (specify upon order) |

| Weight | Approximately 40 kg |

Certification & Approval

|

EU Declaration of Conformity |

|

ISO 9001:2015 |

|

EAC - The Eurasian Conformity mark |