Over the last 20 years, Dynisco Polymer Test equipment has gone through several changes, in order to adapt to the forever evolving landscape of technology.The requirements of our customer’s have helped to define the latest revisions of our laboratory and online analytical equipment, and our goal is to support both legacy equipment, and our current product offering for many years to come.

We offer more than just product delivery...

Our task is not only to deliver a high-quality product, but also to help by sharing our knowledge and experience with you. By doing so, we save you time and money, and enable you to focus on other important aspects of your business.

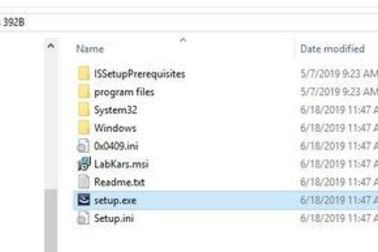

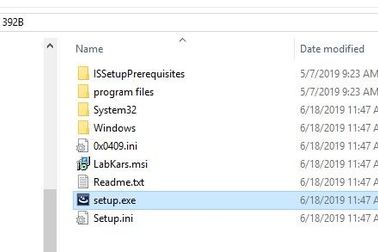

Installation of LABKARS 3.92 on windows 10

At Dynisco, we have been helping polymer processors closely monitor and control their process to improve safety conditions and produce consistently higher quality products by providing analytical equipment for verifying material specifications.Our proven customer commitment drives the continued development and innovation of process products that improve efficiency and help decrease costs.

Causes of Transducer Field Returns & Solutions

Damage to a pressure transducer is commonly caused by their installation into an improperly machined hole. In forcing a transducer into a too-small or eccentric hole, the transducer diaphragm may be crushed and as a result the instrument will not function.

Coping with Transducer-Crippling Pressure Spikes

Many transducers in fluid power systems fall victim to short-duration pressure overloads– commonly called pressure spikes. If these spikes are severe enough, a permanent, positive zero shift in the transducer's output can occur.After investigating these spikes, we developed a laboratory method for determining the magnitude of the actual pressure spike that caused a specific field failure. The method shows that pressure spikes many times that of nominal system pressure can occur in a system.

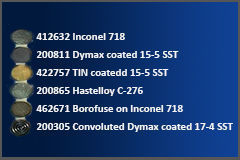

Diaphragm Material Selection

For over 60 years, Dynisco pressure sensors have been used in various applications around the world. The original patent holder for the melt pressure sensor used in extrusion, Dynisco has remained the world class industry leader in this technology by working side by side with our end users to meet the ever changing demands of the plastics market.

Mercury Fill Sensors

A transducer is an electronic device that converts energy from one form to another. In the case of a Dynisco pressure transducer, the process fluid exerts a pressure force on a thin flexible metal diaphragm at the tip of the sensor. This, in turn, stresses a small sensing device called a strain gage. This strain gage then converts the pressure stresses to a low level millivolt signal, which can be further conditioned to yet another signal type.

The Value of Dynisco Instrumentation

When considering a pressure monitoring or control system, Dynisco strongly recommends utilizing local, discrete indicators and controllers to complement our precision sensors, and the following sections will introduce the value these instruments add.

Calibration of Dynisco Pressure Sensors

A sensor is any device that provides measurement of a physical value, by converting this value into a signal output that can be observed by an operator or instrumentation. Pressure Sensors are used in various applications, to help operators monitor and control process stability, while maintaining equipment safety.