EA - Easy Acces

All members of the EASY ACCESS centrifugal pellet dryer series from Gala offer wide doors which permit easy, convenient and safe access for internal cleaning and maintenance. All Gala pellet dryers are supplied with door timed interlocks and local power disconnect for operator safety in polymer manufacturing.

Easy to clean

Low maintenance

Large, wide door

Safety interlock timed by the door

Output from 1,000 kg / h to 85,000 kg / h

ECLN Model - Easy Clean/Low Noise

Easy Clean/Low Noise

Easy-Clean Low-Noise (ECLN) pellet dryers are particularly easy to service and meet high demands on noise reduction < 80 dB(A). Features:

Easy to clean

Low noise

Isolated housing

Security door locks

Output from 1,000 kg / h to 50,000 kg / h

Model SC - Self-Cleaning

Self-Cleaning

The Gala Self-Cleaning Pellet Dryer is designed to achieve a high degree of self-cleaning which will reduce the otherwise common downtimes to a minimum. In most cases, this centrifugal pellet dryer does not need to be cleaned and nor opened to prepare the system for a color change.

Easy to clean

Low noise

Isolated housing

Safety interlock timed by the door

Output up to 2,500 kg / h

CYCLO®

Efficient centrifugal dryer for any application

CYCLO® is energy-efficient pellet drying with minimal space required. The dryers are suitable for use with both PEARLO® underwater pelletizing and M-USG and P-USG underwater strand pelletizing systems. Well thought-out and highly accessible components, such as the core rotor device, serve to provide excellent operating characteristics and efficient servicing.

CENTRO centrifugal dryer

Energy-efficient drying with minimal required space

The CENTRO series of dryers is suitable for use with both underwater pelletizing and underwater strand pelletizing systems. Well thoughtout and highly accessible components, such as the core rotor device, serve to provide excellent operating characteristics and efficient servicing.

Excellent pellet quality

Compact design

Pneumatic interlock

Integrated pre-dewatering

Easy exchange

Special design

Adjustable rotor speed

Self-cleaning system

High-Capacity Model

MAAG/Gala is the market leader for high capacity dryers. Large resin producers have the need for high capacity, continuous operation pellet dryers. By utilizing patented processes and innovative equipment designs, MAAG/Gala is capable to manufacture centrifugal pellet dryers with outputs up to 150 metric tons per hour (330,000 lbs/hr). Design innovations such as segmented rotor designs, wedge wire rotor screens, leak proof bearing seals in combination with high quality steel options assure our customers highest reliability. All MAAG/Gala pellet dryers are supplied with door timed interlocks and local power disconnect for operator safety.

Heavy duty construction

Designed for high capacity, continuous use

Designed for long-term production

Door safety interlocks

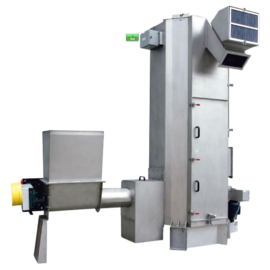

Centrifugal Dryer for Recycled Products

Centrifugal Dryer for Recycled Products

Pellet dryer designs are based on current product rate testing. Gala has been conducting extensive testing on our centrifugal recycled plastic pellet dryers at full production rates since early 2007.

Door timed interlocks

Easy access

FEA designed

Clean operation

Low noise emissions

Low energy consumption

Suitable for various applications

Minimum floor space

Proven reliability

AERO

Gentle drying of plastic pellets

The AERO impact dryer provides for gentle, low-impact separation of cooling water in connection with M-USG underwater strand pelletizing systems.

Very gentle drying of pellets

Minimum residual surface moisture of the pellets

Recirculates process water back into the process loop, reducing water consumption

Good access makes cleaning easier

Optional noise protection cover for the fan

DURO

Efficient pellet drying technology for abrasive pellets

The DURO belt dryer in combination with the underwater pelletizing systems from Gala and Automatik is the perfect solution for the production of abrasive or brittle pellets such as compounds highly filled with fiber glass or minerals. The drying process does not use any rotating parts and thus is a very gentle process reducing costs related to wear to a minimum.

The most gentle handling of pellets

Minimal dust

High product quality

Minimized life cycle costs

TUMBLER™

Pellet Processing Systems for the Plastics and Adhesive Industries

The Gala Tumbler may be used as a defluidizer or dryer for brittle products, a pellet coater for tacky products, or a pellet classifier for any type of product.

Aluminum case

Stainless steel drum

Folding doors

Leveling equipment

The drum can be completely removed

May absorb solids or liquids