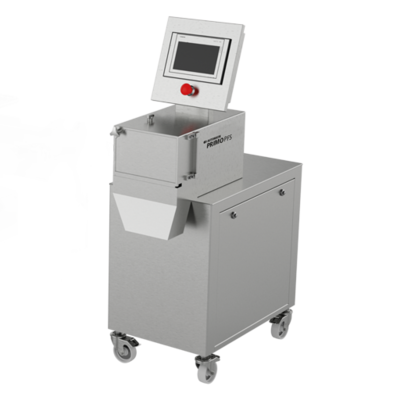

PRIMO PFS

The widely tried and proven dry-cut strand pelletizer produces top quality cylindrical or micro-pellets, which are ideal for further downstream processing. Its compact design makes the strand pelletizer very suitable for lab applications. The variable system configuration enables a perfect adaptation to the product being processed with high flexibility when changing products

Particle size distribution

Homogeneous pellet shape

Quick and easy cleaning

Process space

Geometry for optimal cut

Length setting

Process data monitoring

Easy scaling

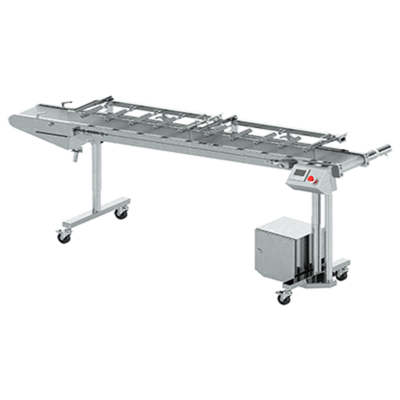

Strand Cooling Belt PFS

Unlike conventional extrusion in a water bath, the Strand Cooling Belt PFS does not require manual threading of strands. Strands are deposited directly on the conveyor belt and automatically conveyed to the strand pelletizer. The cooling is done by special air nozzles with high cooling capacity.

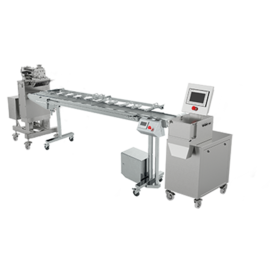

Belt-Cooling Pelletizing System PFS Series 30

The Belt-Cooling Pelletizing System PFS is specially designed for water-soluble and brittle formulations. The variable configuration of the system allows perfect adaptation to the processed product and guarantees continuous production. Even elastic and very flexible polymers can be handled easily and efficiently with the belt system.

Rheologically designed tapping head

Pneumatic suction start

Particle size distribution

Homogeneous pellet shape

Quick and easy cleaning

It is possible to retrofit existing extrusion lines

Process data monitoring

Integration to a higher level of DCS is possible