Melt Flow Indexer Accessories - Black Box

Accessories can be ordered separately or as a complete set in the form of a complete "black-box" case.

LMI 4000 series

LMI 5000 series

LMI 5500 series

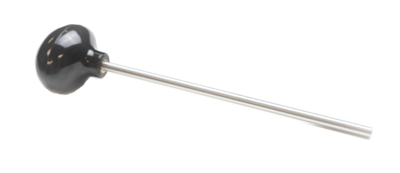

Orifice Remover Tool

This tool is used to remove the capillary from the melt flow indexer barrek before the cleaning process. The piston to remove the capillary has to be inserted from the bottom side of the barrel and then the capillary is pushed upwards out of the instrument. For instruments that have an automatic cut-off system, a tool code HEX-030 must be used.

LMI 4000

LMI 5000

LMI 5500

Orifice Remover Tool - AutoCut

This tool is used to remove the capillary from the barrel of the melt flow indexer with AutoCut before the cleaning process. The piston is inserted from the botttom of the barrel to remove the capillary, and then the capillary is pushed upwards out of the instrument.

LMI 5000

LMI 5500

Charging Tool

This tool is used to fill and pack polymer samples into the barrel of the melt flow indexer and can be used with both types of powder or pellets or other types of polymers.

LMI 4000

LMI 5000

LMI 5500

Cleaning Tool

This tool is used to clean the chamber of melt flow indexer films and residue. One or two cotton patches are placed on the tool and the walls of the melt flow indexer barrel are cleaned by moving up and down. The capillary must be removed during this cleaning process, otherwise there is a risk of damage to the capillary.

LMI 4000

LMI 5000

LMI 5500

Beaker, 10mL

Glass beaker for measuring the sample. Can be used for powder mixtures and granulates.

LMI 4000

LMI 5000

LMI 5500

Pin Vise

The swivel head of the pin vise (drill body) offers comfortable operation. Thanks to the double-ended pliers, different drill bit sizes can be stored. For better control, the pin vise body is made of grooved aluminium. Under the swivel part of the handle, there is an additional pincer, which is suitable for larger drill bits. The flared end of the pin vise body is used for hanging in the accessory rack

Swivel head

Two pliers

Grooved body

Aluminium construction

LMI 4000

LMI 5000

LMI 5500

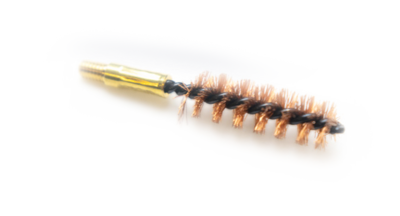

Bronze Scoring Brush

Copper brush for cleaning residue in the melt flow indexers barrel. Its thread is in inches and is compatible only with the original handle supplied with the instrument or can be reordered according to part number:0051-47. Or use the replacement:B0555CZ

LMI 4000

LMI 5000

LMI 5500

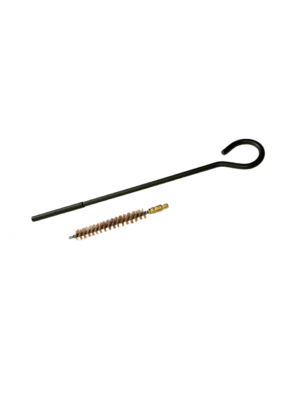

Long brush barrel

The copper brush with extended adapter is used for manual cleaning of thick residues and burns in the barrel of a melt flow indexer or rheometer. Due to the softness of the material, you do not have to worry about damaging the instrument barrel. Thanks to the extended length, it lasts longer and removes more dirt per cleaning than standard brushes. It is mainly ideal for materials such as PET/PET/PC and additives that cause burns due to residual moisture, for example, and is very difficult to clean with cotton patches .

LMI 4000

LMI 5000

LMI 5500

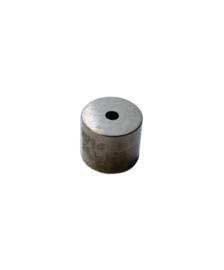

Standard capillary 2,095 mm / 8 mm

Standard capillary for Dynisco plastometer with an inner diameter of 0.95 mm and a length of 8 mm. The capillary is identical on both sides and is coated with a layer of Wolram Carbide, which gives the capillaries greater hardness and longer life. The capillary is used for all standard polymeric materials up to a flow index range of 0.1 [g / 10min] to 80 [g / 10min]. For higher indices, we recommend using a so-called half-capillary with half dimensions.

LMI 4000

LMI 5000

LMI 5500

Tungsten carbide

Laser marking

Half capillary 2,095 mm / 8 mm

The half capillary is used for polymeric materials with very low viscosity. These materials, which achieve flow indices higher than 80 [g / 10min], will slow down and their testing will be no problem. If you are going to use a half capillary, you need to adjust the capillary plastometer settings and record this change in settings.

LMI 4000

LMI 5000

LMI 5500

Tungsten carbide

Laser marking

Go/No-Go Roller Calibre for Capillary

Cylindrical certified calibre for checking the capillary to the Dynisco melt flow indexer. The green end of the caliper must pass through the inner diameter of the capillary but the red end of the caliber must not pass through the diameter of the capillary. If the red end of the roller gauge passes through the capillary, it means that the capillary's inner diameter does not meet the required specifications and must be replaced.

Go / Not Go

Double-sided caliber

Green = OK

Red = replacement required

Certificate