Filtration systems and screencangers for industrial applications

Filtration is a process that separates or purifies substances. The mechanical separation processes of Maag filtration systems are physical. The principles are used in filters and screen converters for separating and cleaning plastic melts, chemicals and lubricants. They are also used in recycling, extrusion, rotational molding, in general in industrial applications and in the pharmaceutical and food industries.

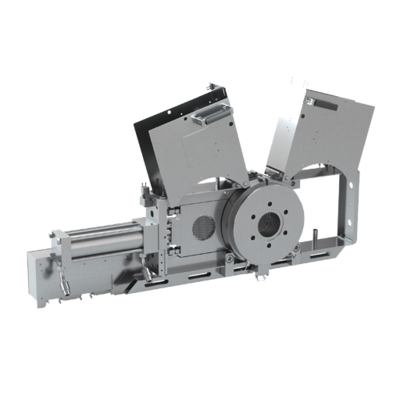

FSC-OEM

Optimized flat screen changer for processing of plastics

The flow optimized new version of MAAG´s FSC hydraulic and manual screen changers assist operators of plastic extrusion lines in achieving a reduced equipment footprint, reduced residence time and improved residence time distribution.

Reduction of pressure loss

Optimized flow

Increased production speed

Energy efficiency

Elimination of pressure fluctuations

Reduction of material consumption

Easy maintenance

DSC - Single piston screen changer for extrusion and compounding applications

Discontinuous DSC screen changers from MAAG with their robust and leak-free operation meet highest quality standards with respect to melt filtration. Due to their constantly improved functionality continuous screen changers from Maag increase product quality significantly. DSC screen changers are based on the proven single-piston design that operates without any additional seals. Their sturdy construction available in all sizes and designs guarantees a reliable and leak-free filtration of polymer melts for many years.

Suitable for Masterbatch, Compounding, Recycling, Extrusion, Hot Melt Adhesives

Simple operation and uncomplicated screen changing

High operational reliability

Short material residence time

Leak-free mode of operation

Low pressure consumption

Flow channel geometry without any dead spots

SSC

Effective single piston screen changer for reliable melt cost effective filtration solution

The compact single-piston screen changers SSC from MAAG provide a cost-effective filtration alternative for extrusion applications which allow for interruptions in the melt stream during screen changeovers. SSC operate without any additional seal.

Simple operation and uncomplicated screen changing

High operational reliability

Short material residence time

Leak-free mode of operation

Low pressure consumption

Flow channel geometry without any dead spots

FSC - Hydraulic plate screen changer for filtration systems and polymer production

FSC screen changers from Maag are equipped with a pressure-adaptive sealing system as a standard. Thanks to this sealing system, the required sealing forces are adjusted to the actual melt pressure automatically. The narrow design is especially suited for being used in applications with thermally sensitive materials. Their solid and robust construction, available in all sizes and designs, ensures a reliable and leakfree filtration of molten polymers for many years. The hydraulically operated screen changer reliably guarantees the protection of melt pumps and mold gaps from damage and dirt.

Suitable for Compounding, Recycling, Extrusion, Masterbatch

Simple operation and uncomplicated screen changing

High operational reliability

Short material residence time

Leak-free mode of operation

Low pressure consumption

Flow channel geometry without any dead spots

HSC - Manual screen changer and plate screen changer for filtration solutions and extrusion processes

Manual screen changers from Maag have been the first choice of cost-effective filtration systems in extrusion lines for many years. Starting at size 45, the manual screen changers optionally come with transmission gearing. Here, the breaker plate is equipped with patented gearing and a pinion which allows an effortless screen change even in restricted space conditions or high sealing pressures. The manual screen changer guarantees the protection of gear pumps and fine extrusion die gaps from damage and dirt accumulation.

Suitable for Recycling, Extrusion

Simple operation with quick screen change

High operational reliability

Short material residence time

Leak-free mode of operation

Low pressure consumption

Flow channel geometry without any dead spots

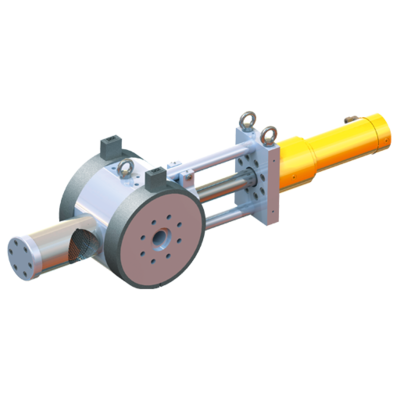

CSC - Continuous screen changers and double pistion screenchangers for filtration systems

Continuous CSC screen changers from MAAG with their robust and leak-free operation meet highest quality standards with respect to melt filtration. Due to their constantly improved functionality continuous screen changers from MAAG increase product quality significantly. CSC screen changers are based on the proven double-piston design that operates without any additional seals. Their sturdy construction available in all sizes and designs guarantees a reliable and leak-free filtration of polymer melt for many years.

Suitable for¨Rotomolding, Hot Melt Adhesives, Resin & Virgin Polymer Production, Masterbatch, Compounding, Recycling, ExtrusionSimple operation and uncomplicated screen changing

High operational reliability

Short material residence time

Leak-free mode of operation

Low pressure consumption

Flow channel geometry without any dead spots