Differential Pressure Transducer Model 274

The Model 274 Differential Pressure Transducer measures pressure ranges from 5" W.C. to 100 PSID and provides a 0-5 VDC signal. All wetted surfaces, including flanges and diaphragms, are constructed of 316 stainless steel with a sealing Viton® O-Ring for excellent corrosion resistance. A standard 1,000 PSI static line pressure and single side overpressure rating are featured with these transducers. For applications that require a higher static line pressure rating, 3,000 PSI is available with optional flanges.

Model 274 also features an internal calibration circuit for easy field set-up, a quick disconnect electrical connection and external zero and span controls. A special option called fast response enables the unit to accurately respond to changes in pressure in approximately one tenth of the standard time.These features make the Model 274 ideal for most industrial test and flow applications.

PERFORMANCE

| Full Scale Pressure Ranges | 0-5, 10, 20, 50, 100, 300, 750" W.C.D. 0-15, 50, 100 PSI |

|

| Nonlinearity (Best Fit Straight Line) | ≤±0.15% FSO | |

| Hysteresis | ≤±0.08% FSO | |

| Repeatability | ≤ ±0.06% FSO | |

| Full Scale Output (FSO) | 5 Vdc at 70° F | |

| Resolution | Infinite | |

| Long Term Stability | ≤±0.1% FSO per 6 months | |

| Zero Shift with Base Pressure | 5” WC to 100” WC : ≤ 4% 300” WC to 100 PSI: ≤ 6 |

|

| Span Shift with Base Pressure | 5” WC to 100” WC : 0 to -6% 300” WC to 100 PSI : 0 to -4 |

|

| Zero Shift After 1000 PSI Overload | Single Side: ≤± 0.1% FSO Alternate Sides: ≤±0.5% FS |

|

| Compensated Temperature Range | 70°F to 170°F (21°C to 76°C) | |

| Operating Temperature Range | 0° F to +200° F | |

| Storage Temperature Limits | -40°F to +250°F (-40°C to 121°C) | |

| Temperature Effect on Zero | ≤± 2.0% FSO per 100° F | |

| Temperature Effect on Span | ≤± 2.0% FSO per 100° F |

ELECTRICAL

|

Supply Voltage:

|

10 to 42 Vdc

|

|

|

Power Supply Regulation

|

≤±0.0001% FSO per Volt change over the supply voltage range

|

|

|

Output Signal

|

0 to 5 Vdc

|

|

| Load Impedance | 3000 Ohms minimum | |

| Current Draw | 3.8 mA | |

| Zero Adjustment | ± 10 % FSO min. / ±20% FSO max. | |

| Span Adjustment | ± 10% FSO min. / ±20% FSO max. | |

| Calibration Signal | 80% of the FSPR, by shorting pins E & F | |

| Calibration Signal Accuracy | ≤±0.1% of the stated value | |

|

Circuit Protection |

Reverse polarity protected | |

| Insulation Resistance | >1000 MegOhms to case ground at 50 Vdc and 70° F | |

| Response Time | 10% to 90% FS Faster response available with NF option. | |

| Electrical Connection | Bendix PT02E-10-6P, mates PT06E-10-6S (SR) | |

|

Pin Outs |

Pin A + Power Pin B - Power Pin C + Signal Pin D - Signal Pin E Calibrate Pin F Calibrat |

MATERIALS OF CONSTRUCTION

|

Wetted Materials

|

316 Stainless steel and Viton O-Ring

|

|

|

Housing

|

304 and 316 Stainless Steel with an Aluminum alloy, black zinc-cobalt plated electrical connector

|

|

| Weight | 3.5 lbs. (6.5 lbs. with optional flanges) | |

|

Identification

|

Laser etched onto body

|

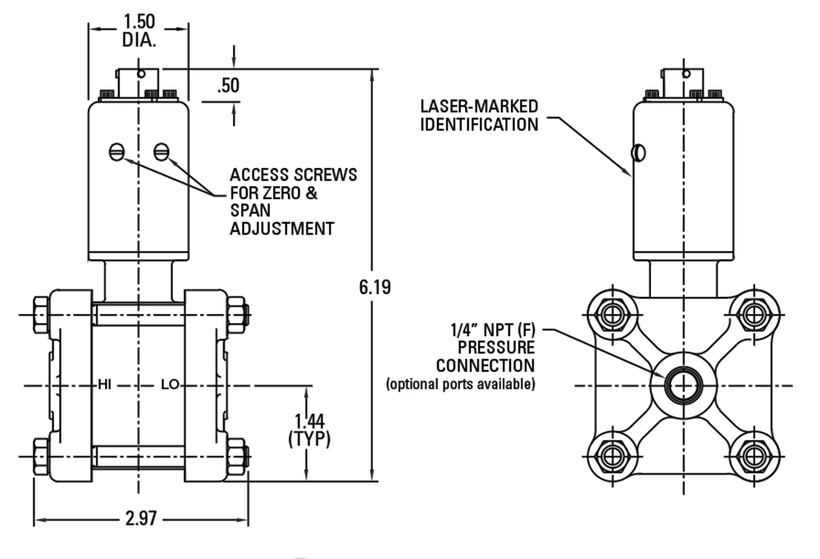

MECHANICAL

|

Pressure Connection:

|

1/4" - 18 NPT female

|

|

| Static Pressure | 1000 PSI maximum (3000 PSI - optional) | |

|

Proof Pressure

|

1000 PSI single sided (3000 PSI - optional)

|

|

| Burst Pressure | 1500 PSI (4500 PSI - Optional) | |

| Diaphragm Displacement |

0.002 cubic inches at FSPR |

|

| Diaphragm Displacement | Standard Flanges: 0.4 cubic inches Optional Process Flanges : 1.5 cubic inche |

|

| Fill Fluid | Dow DC200 Silicone oil | |

| Mounting | May be supported by process piping or by optional mounting bracket |

DIMENSION