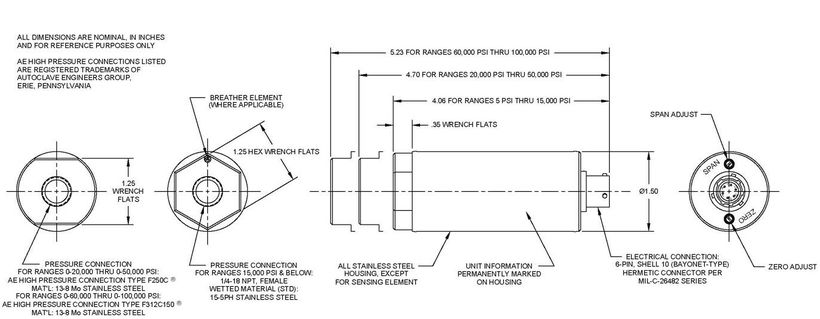

Model 349 Pressure Transmitter

The Model 349's small size allows flexibility in tight spaces, while the welded body, stainless steel connector and sealed adjustments ensure protection against contamination.

The “49” series utilizes three sensor technologies to achieve top performance through all pressure ranges. For ranges 0-5 to 0-150 PSI, a silicon piezoresistive sensor provides extremely accurate readings and high overpressure protection. Bonded foil strain gage sensors are more reliable for pressure ranges 200 to 15,000 PSI where transient spikes could destroy a silicon sensor.

For pressure measurement over 20,000 PSI, Viatran developed the “tube” sensor. Made from high strength stainless steel, this sensor ensures high accuracy and durability where diaphragm type sensors can rupture.Model 349 is equipped with electronic linearization, a compensation circuit that corrects for non-linearities in the sensor.

Surface-mount technology (SMT) allows this complex circuitry to be incorporated into a small package and yield a linearity specification of ≤0.1% FSO (optional to 0.05%). Encapsulation of the surface-mount components of the PC board helps to prevent damage from severe vibration with top-mounted and sealed zero and span adjustments. An internal calibration circuit permits easy 2-point calibration without an external pressure source.

Optional performance features of the “49” series include improved accuracy, temperature compensation, special ranging, modified output, and alternate pressure ports.

PERFORMANCE

| Full Scale Pressure Ranges | 0-5, 15, 25, 50, 100, 200, 300, 500, 1K, 1500, 2K, 3K, 5K, 7.5K,10K, 15K, 20K, 25K, 30K, 40K, 50K, 60K 75K, 100K PSIA, PSIS, PSIG | |

| Linearity (Best Fit Straight Line) | ≤±0.10% FSO For 100K PSI ≤±0.25% FSO |

|

| Hysteresis | ≤0.06% FSO | |

| Repeatability | ≤0.03% FSO | |

| Full Scale Output (FSO) | 16 mA | |

| Long Term Stability | ≤±0.25% FSO per 6 months | |

| Response Time | ≤4 mSec to reach 90% of FSO | |

| Temperature Effect on Zero | ≤±1% FSO per 100°F (37°C) | |

| Temperature Effect on Span | ≤±1% FSO per 100°F (37°C) | |

| Compensated Temperature Range | 70°F to 170°F (21°C to 76°C) | |

| Operating Temperature Range | -40°F to 185°F (-40°C to 85°C) | |

| Storage Temperature Limit | -65°F to 250°F (-54°C to 121°C) |

ELECTRICAL

|

Supply Voltage

|

9 to 40 Vdc

|

|

|

Power Supply Regulation Effect

|

≤±0.01% FSO per Volt

|

|

|

Output Signal

|

4 to 20 mA

|

|

| Load Impedance | 1500 Ohms max at 40 Vdc max | |

| Bridge Impedance | 5,000 Ohms nominal | |

| Circuit Protection | Output may be short-circuited indefinitely. Input polarity may be reversed. Over voltage protection to 1000 volts for <1 mSec duration | |

| Electrical Connection | 6-pin hermetic, bayonet-style, 303 SST weld mount connector | |

| Pin Outs | PIN A +Signal PIN B -Signal PIN C Calibrate PIN D Calibrate PIN E No Connection PIN F No Connectio |

MECHANICAL

|

Pressure Connection

|

0-5 thru 0-15K PSI

1/4" - 18 NPT Female (0-3.3 thru 0-1034 bar) 0-20K thru 0-50K PSI 1/4" F250-C High Pressure Tube (0-1378 thru 0-3447 bar) 0-60K thru 0-100K PSI 5/16" F312C High Pressure Tube (0-4136) thru 0-6894 bar) |

|

|

Proof Pressure

|

5 thru 150 PSI 3X range minimum

151 thru 15K PSI 1.5X range 20K - 100K PSI 1.2X range |

|

|

Burst Pressure

|

5 thru 150 PSI Consult Factory

151 thru 15K PSI 5X range or 30K PSI, whichever is less 20K - 100K PSI 1.5X range or 125K PSI, whichever is less |

|

| Pressure Cavity Volume | 5 thru 150 PSI 0.25 cu. in. 151 thru 15K PSI 0.32 cu. in. 20K - 100K PSI 0.10 cu. in. |

|

| Mounting | Supported by process piping or optional mounting bracket |

MATERIALS OF CONSTRUCTION

|

Wetted Parts

|

5 thru 150 PSI - 316, 304 SST

200 thru 15K PSI - 15-5 PH SST 20K - 100K PSI - Stainless Steel |

|

|

Housing

|

316L SST

|

|

|

Weight

|

15 oz, nominal

|

|

| Identification | Laser etched onto body |