SPX5390

The Dynisco SPX 5-Series is a smart 4-20mA pressure transmitter that includes DynalarirtyTM , a Dynisco innovation that uses an advanced algorithm that will linearize offsets due to process effects on the sensor. The SPX 5-Series is an all welded construction designed for use in hazardous locations and is available with a variety of process and electrical connections. These amplified transmitters eliminate the need for external signal conditioning. All models can interface directly with distributed control systems, PLC's, computers, and similar high level control devices. Optional thermocouple or RTD configurations are available to provide melt temperature

All sensors in this series can be configured according to your needs. Contact us, we will be happy to help you.

Dynisco SPX 5 Series Smart Pressure Sensor

Dynisco SPX 5 Series Smart Pressure Sensor

Dynisco SPX 5 Series Smart Pressure Sensor

Dynisco SPX 5 Series Smart Pressure Sensor

Dynisco SPX 5 Series Smart Pressure Sensor

Dynisco SPX 5 Series Smart Pressure Sensor

Dynisco SPX 5 Series Smart Pressure Sensor

Dynisco SPX 5 Series Smart Pressure Sensor

Dynisco SPX 5 Series Smart Pressure Sensor

Dynisco SPX 5 Series Smart Pressure Sensor

Dynisco SPX 5 Series Smart Pressure Sensor

Inquiry system

Configure your own product, according to your requirements and needs. If you are not sure about the configuration, tell us in the notes the necessary information about the existing sensor or product, even a competitor. We will be happy to help you find an alternative Dynisco product. If your request is urgent, let us know, we will do our best to help you resolve this situation to your satisfaction as quickly as possible. If we have all the information, we are able to offer a model with minor differences, which is in stock and you can have the necessary product the next day.

SPX 5-series - Pressure sensor - model:

General Purpose Smart Pressure Sensors for Hazardous Locations

SPX 5-Series

The Dynisco SPX 5-Series is a smart 4-20mA pressure transmitter that includes DynaLarity™, a Dynisco innovation that uses an advanced algorithm that will linearize offsets due to process effects on the sensor. The SPX 5-Series is an all welded construction designed for use in hazardous locations and is available with a variety of process and electrical connections.

The SPX5 Series includes models SPX5342, SPX5343, SPX5344, SPX5390, SPX5391, and SPX5392.

⚠ WARNING: This product can expose you to chemicals including mercury and lead, which is known to the State of California to cause cancer and reproductive harm. For more information, go to www.P65Warnings.ca.gov.

SPX5390 Series

The Dynisco SPX 5-Series is a smart 4-20mA pressure transmitter that includes DynalarirtyTM , a Dynisco innovation that uses an advanced algorithm that will linearize offsets due to process effects on the sensor. The SPX 5-Series is an all welded construction designed for use in hazardous locations and is available with a variety of process and electrical connections. These amplified transmitters eliminate the need for external signal conditioning. All models can interface directly with distributed control systems, PLC's, computers, and similar high level control devices. Optional thermocouple or RTD config

Performance Characteristics

| Output: |

4 - 20 mA, with optional HART™ |

| Input Voltage: |

16 - 36 Vdc (Std); 16 - 30 Vdc (ATEX IS) |

| Accuracy: |

All Models ± 0.20%

Accuracy is defined as the combined error expressed as a percentage of full scale output with the specifications of: Electronics ambient temperature, capillary of <= 36"; DyMax coated 15-5 SST diaphragm; Best Straight Line (BSL) %FS, per ISA-37.1 Consult Factory for availability and specifications of other configurations

|

| Repeatability: |

±0.1% |

| Rangeability: |

3:1 Turndown |

| Over Pressure: |

2X FSO or 35,000 psi,whichever is less (5390, 5391, & 5392 1.5 x FSO for 10,000 psi) |

| Zero Balance Adjustment Range: |

-40% to +10%; -80% to 20% for FSP < 500 psi |

| Load Resistance |

500 Ω @ 24 Vdc, 1,000 Ω @ 36 Vdc |

| Electronics Ambient Temperature: |

70°F (20°C) |

| Electronics Operating Temperature: |

-20 to 185°F (-29 to 85°C) |

| Diaphragm Temperature: |

750°F (400°C) max [Models 5344, 5390, 5391, 5392 limited to 600°F (315°C)] |

| Electronics Compenstated Temperature Range: |

0 to 150°F (-18 to 65°C) |

| Zero Shift (Electronics Temp Change): |

All Models: 0.01% F.S./°F max (0.02% F.S./°C max) |

| Span Shift (Electronics Temp Change): |

All Models: 0.01% F.S./°F max (0.02% F.S./°C max) |

| Zero Shift (Snout Temp Change): |

5344/5390/5391/5392: 1 psi/100°F (from 75-450°F) typical 2 psi/100°F (from 450-600°F) typical

5342/5343: 15 psi/100°F (27 psi/100°C) typica

|

Mechanical Characteristics

| Mounting Torque: |

5342: 500 inch-lbf max

5343: 50 inch-lbf max

5344: 350 inch-lbf max

5390: 350 inch-lbf max

5391: 350 inch-lbf max

5392: 80 ft-lbf max

|

| Standard Wetted Parts: |

DyMax coated 15-5 PH SST |

Approvals & Certifications

| ATEC/IECEx Intrinsically Safe |

|

| SIL 2 (pressure output) & PL'c' (relay output) |

|

| FM & CSA Explosion Proof |

|

| Additional approvals available (consult factory) |

|

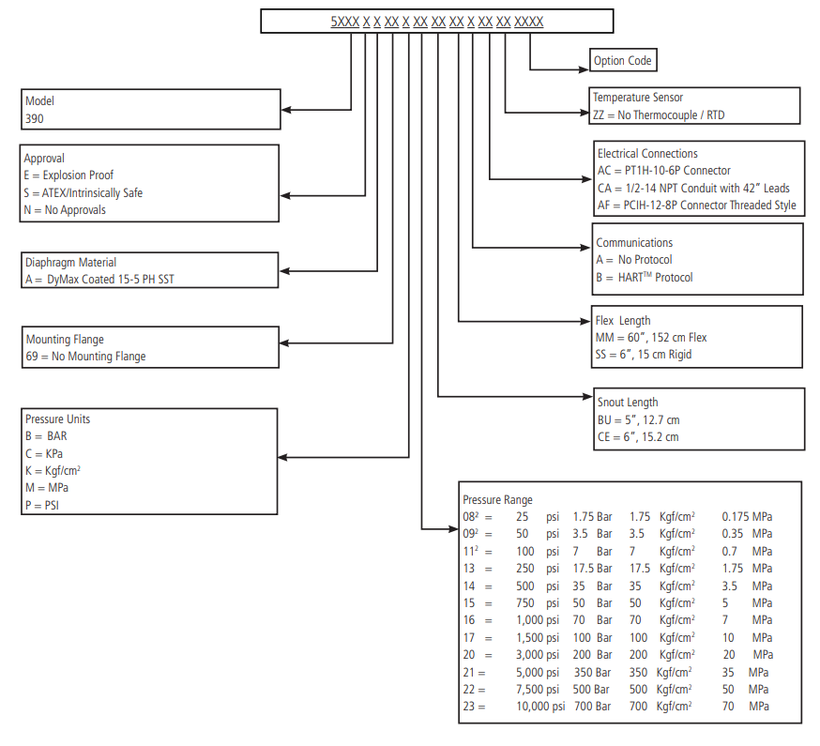

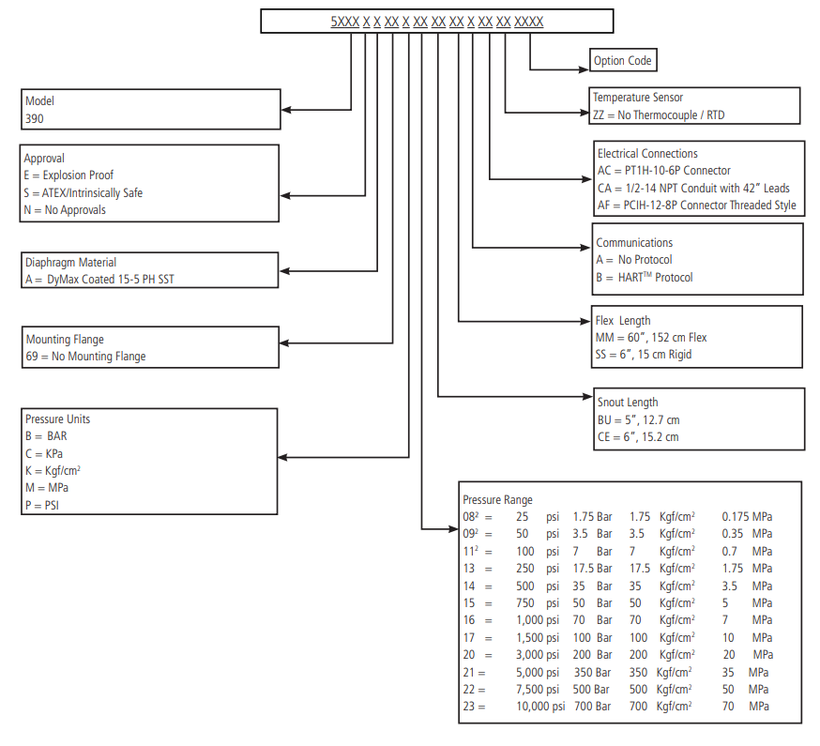

Ordering Guide for Models SPX5390 Series

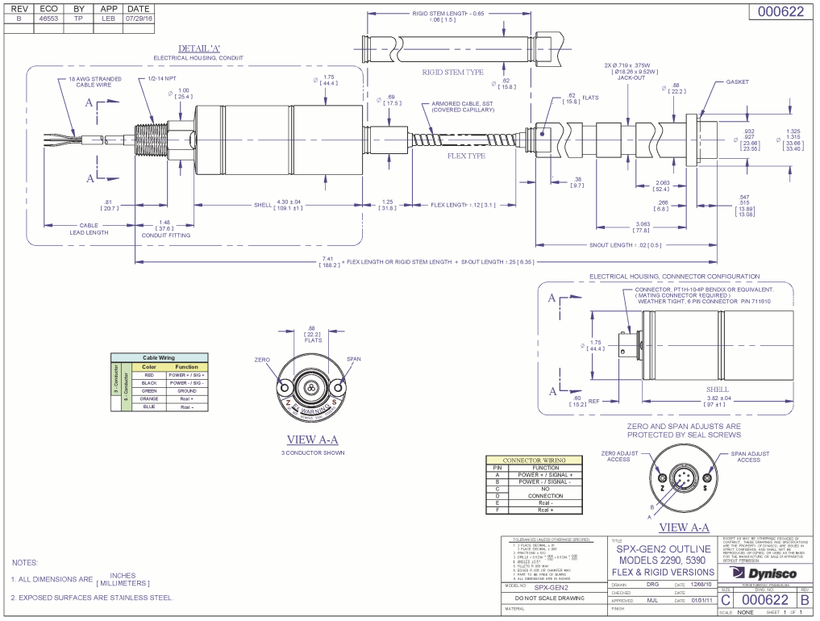

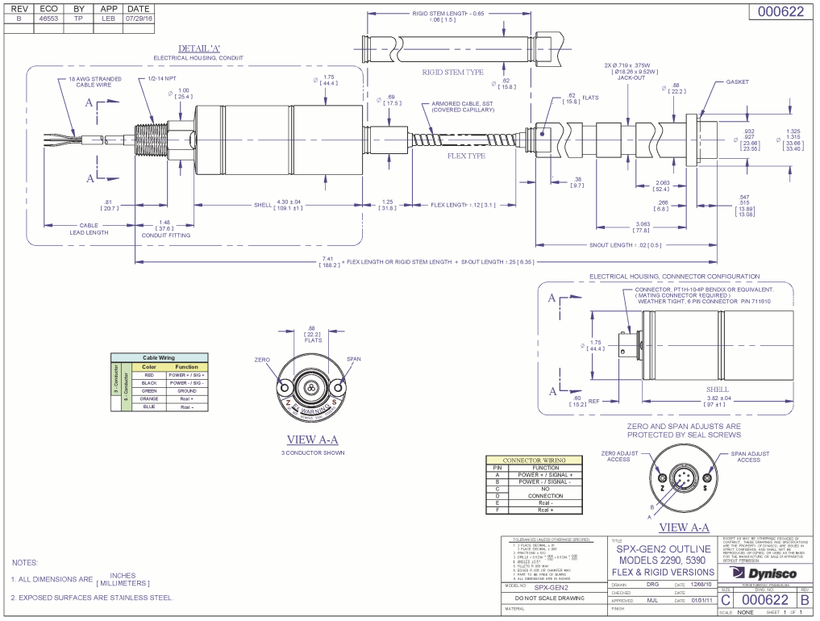

SPX5390 Series - Dimensions

All dimensions are inches (mm) unless otherwise specified.

Installation of transducers into improperly cleaned or sized holes is one of the major causes of damage to these instruments. With this kit, the .312" tip diameter hole, the 45 degree seating surface, and the .451" hole can be cleaned. The kit includes a gauging plug which is used to verify that the hole has been correctly machined and cleaned. M10 and M18 cleaning kits also available.

The Dynisco Transducer Mounting Hole Machining Tool Kit contains all of the necessary drills and taps to prepare a standard 1/2 - 20 UNF transducer mounting hole and the 45 degree seat. All tools included in this kit are made of premium grade, high strength tool steel. Care should be taken in the use of proper speeds and feeds, lubricants, and a method to assure continual alignment of each progressing tool. M10 and M18 kits are also available.

Torque wrench Wera 075611 Click-Torque B 2 with switch ratchet 3/8 "(20 - 100 Nm)

Wera Click-Torque torque wrenches are supplied as switch ratchets (with connection dimensions 1/4 ", 3/8", 1/2 "and 3/4") or with clamping for socket tools (9x12 mm, 14x18 mm) for tightening torques from 2.5 Nm up to 1,000 Nm.

All Wera Click-Torque torque wrenches manufactured in accordance with DIN EN ISO 6789 are supplied with a declaration of conformity.

Certifikati in odobritve

Pregled razpoložljivih certifikatov in odobritev: Obiščite to povezavo, ki vas bo odpeljala na stran s celovitim seznamom trenutnih certifikatov in odobritev za naše izdelke. Tu lahko preverite, ali naša ponudba ustreza najvišjim standardom kakovosti in varnosti. Več informacij

Pregled razpoložljivih certifikatov in odobritev: Obiščite to povezavo, ki vas bo odpeljala na stran s celovitim seznamom trenutnih certifikatov in odobritev za naše izdelke. Tu lahko preverite, ali naša ponudba ustreza najvišjim standardom kakovosti in varnosti. Več informacij

Odkrijte svet naše spletne strani za e-učenje in spoznajte, kako poenostaviti vašo vsakodnevno uporabo naših izdelkov. Naše praktične in celovite tečaje ter informativne materiale vam bodo pokazali, kako poenostaviti in izboljšati uporabo naših tehnologij, razkriti nove informacije in tehnike ter optimizirati delovne procese. S temi viri boste dosegli večjo učinkovitost, prihranili čas in izboljšali rezultate vašega dela. Več informacij

Odkrijte svet naše spletne strani za e-učenje in spoznajte, kako poenostaviti vašo vsakodnevno uporabo naših izdelkov. Naše praktične in celovite tečaje ter informativne materiale vam bodo pokazali, kako poenostaviti in izboljšati uporabo naših tehnologij, razkriti nove informacije in tehnike ter optimizirati delovne procese. S temi viri boste dosegli večjo učinkovitost, prihranili čas in izboljšali rezultate vašega dela. Več informacij

Naši instrukcijski video posnetki ponujajo interaktiven način učenja o naših izdelkih. Združujejo vizualno in zvočno vsebino ter ponujajo praktične rešitve za pogoste težave, s čimer prihranite čas in se izognete morebitnim težavam. Če naletite na težavo, vam naši video priročniki ponujajo podrobna navodila in praktične nasvete za njeno reševanje. Na voljo so kadarkoli in predstavljajo priročen vir informacij, ki dopolnjuje našo tehnično podporo. Več informacij

Naši instrukcijski video posnetki ponujajo interaktiven način učenja o naših izdelkih. Združujejo vizualno in zvočno vsebino ter ponujajo praktične rešitve za pogoste težave, s čimer prihranite čas in se izognete morebitnim težavam. Če naletite na težavo, vam naši video priročniki ponujajo podrobna navodila in praktične nasvete za njeno reševanje. Na voljo so kadarkoli in predstavljajo priročen vir informacij, ki dopolnjuje našo tehnično podporo. Več informacij

Naši tehnični članki nudijo praktičen način za spoznavanje več o naših izdelkih in njihovi uporabi. Zagotavljajo podrobne informacije in praktične nasvete o reševanju pogostih težav, s čimer prihranite čas in se izognete morebitnim težavam. Če še vedno naletite na težavo, naši tehnični članki ponujajo posebna navodila za njeno reševanje. Na voljo so kadarkoli in predstavljajo priročen vir informacij, ki dopolnjuje našo tehnično podporo. Več informacij

Naši tehnični članki nudijo praktičen način za spoznavanje več o naših izdelkih in njihovi uporabi. Zagotavljajo podrobne informacije in praktične nasvete o reševanju pogostih težav, s čimer prihranite čas in se izognete morebitnim težavam. Če še vedno naletite na težavo, naši tehnični članki ponujajo posebna navodila za njeno reševanje. Na voljo so kadarkoli in predstavljajo priročen vir informacij, ki dopolnjuje našo tehnično podporo. Več informacij