Online rheometers have been used increasingly in plastics processing and recycling industry to provide continuous data stream of rheological properties and real-time information with th extrusion process. This is beneficial for the controlling of in-process product quality, reducing one's waste stream, and increasing of process efficiency. Dynisco® ViscoIndicator (VI) online rheometer is designed to duplicate the test conditions of a standard melt flow rate tester and monitor the melt mass flow rate (MFR) and melt volume flow rate (MVR) of the plastics materials while processing in an extrusion line.

Correlation of ViscoIndicator Online Rheometer to a Laboratory Melt Flow Rate Tester

Azadeh Farahanchi, Rheological Scientist, Ph.D

10.02.2018

Online rheometers have been used increasingly in plastics processing and recycling industry to provide continuous data stream of rheological properties and real-time information with th extrusion process. This is beneficial for the controlling of in-process product quality, reducing one's waste stream, and increasing of process efficiency. Dynisco® ViscoIndicator (VI) online rheometer is designed to duplicate the test conditions of a standard melt flow rate tester and monitor the melt mass flow rate (MFR) and melt volume flow rate (MVR) of the plastics materials while processing in an extrusion line. The question many ask is how has Dynisco’s ViscoIndicator been designed to closely duplicate the standard testing condition (ASTM D1238/ISO 1133) of a laboratory melt flow rate tester?

Dynisco's VI online rheometer consists of a gear pump which isolates a side stream of molten polymer from the process and produces a precisely metered flow of the sample through an interchangeable capillary die. Dynisco provides a variety of capillary dies for the online rheometer with various ranges of capillary dimeter and length (e.g. diameter of 2 to 7.5 mm and L/D of 3.818). Even though the VI dies have been designed to have the same L/D ratio as the standard die of a melt flow rate tester, their diameter sizes might vary from that of a standard die (2.095 mm). As a result, correlation factors have been defined in our VI to consider the die diameter variation.

Another important parameter is amount of the driving pressure inside the rheometer. Our VI maintains a preset pressure (which corresponds to the pressure from a standard weight for a specific material in a MFR test) by manipulating gear pump speed. Normally it can be assumed that the pressure drop in the channel of the rheometer is negligible compared to the pressure drop through he capillary die. However, for short capillaries with a large diameter, this error can be significant and needs to be considered.

For a Newtonian isothermal fluid, the pressure of the melt flowing in a capillary can be calculated as equation below:

Where Q is the volumetric flow rate, n is the polymer melt viscosity, L is the capillary length, and R is the capillary radius.

For an incompressible fluid, the ratio of the channel pressure drop to the capillary pressure drop can be shown as below:

The other important parameter is the temperature. Extrusion processing temperature which is same as the set temperature in the online rheometer is not always necessarily same as the standard temperature for a specific material in a MFR test. Therefore, temperature correlation has been considered in the VI to define a shift a factor and correlate the processing temperature to the standard temperature for a specific material.

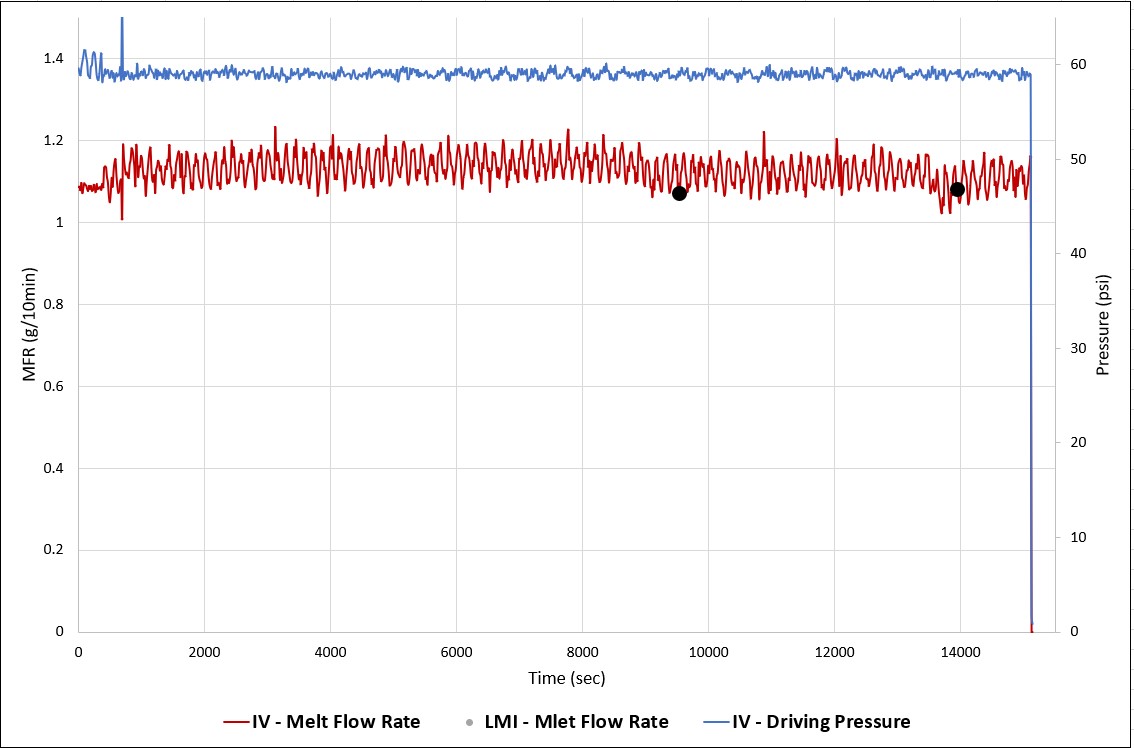

As it can be seen from the image below, recycled high density polyethylene materials were extruded using a sampling extruder at a specific screw speed and head pressure. The extruder was connected to the rheological sensing unit of a VI using a connection heated tube and ½ mounting port which is compatible with the standard pressure port on extruders. The rheometer was run in a pressure mode to maintain a preset pressure of 59 psi. A vertex pressure transducer was mounted inside the rheometer to capture the pressure.

During the test about 10 grams of extrudate materials were collected from the extruder after 2.5 hours and 4 hours and their MFR value were measured in the laboratory using a melt flow rate tester (black circle points). The figure below shows the online reading of pressure (blue line) and MFR (red line) parameters from VI over a specific period.

Online Rheometer and Laboratory Melt Flow Rate Tester Results

A good agreement was found between the online and offline measurement which ensures that the ViscoIndicator is able to continuously control the product quality and open a window in to the process in any manufacturing or recycling industry.

.JPG)