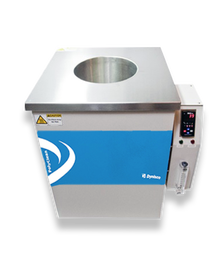

PolyClean 26"

DescriptionThe Dynisco PolyClean 26L Fluidized Temperature Bath can be used to clean extrusion tooling and all other types of hardware, shape set medical devices, calibration, testing various sensors and systems, heat treatment of metals as well as heating of reactors, coils, flasks and containers. Fluidized Temperature Baths typically provide faster processing times than ovens and furnaces and are much more thermally stable and uniform. Fast heat up of immersed parts and objects is another major advantage. Fluidized baths are safer to operate than molten salt baths while immersed objects come out clean and dry with no material to remove. The PolyClean uses a PID temperature controller that has four control zones for improved thermal results. Independent over temperature protection will disable heat if the temperature exceeds 615 °C or in the event of a system failure.

Features

■ Fully automate fluidizing air control

■ Independent over-temperature protection

■ Advanced PID temperature controller for optimumresults

■ Built rugged for years of reliable operation

■ Cleans most tooling in under 60 minutes

■ Removes all types of polymer, paint, adhesives andresins

■ Large working volume – up to 8.4” diameter by26" depth in the part basket

■ Up to 6500 watts of heat capacity for fast heat up

PolyClean Model 6L:

The PolyClean 6" Fluidized Temperature Bath can be used to clean small tooling from Laboratory Extruders ar lnjection molding machines, Capillary Rheometer and Melt Flow lndexer dies ar other small components used in polymer testing ar small part production. 5.3" X 6" Deep (134mm X 152mm)

PolyClean Model 12L:

PolyClean Model 26L:

The PolyClean 26" The PolyClean 26" Fluidized Temperature Bath can be used to clean tooling from all extrusion, injection molding, blow molding, and laboratory applications. lts 26" deep basket is designed to handle a large variety of components from laboratory as well as production environments. 1 O" X 12" deep (8.4" diameter when using parts basket) and (213mm X 305mm)

The PolyClean 26" The PolyClean 26" Fluidized Temperature Bath can be used to clean tooling from all extrusion, injection molding, blow molding, and laboratory applications. lts 26" deep basket is designed to handle a large variety of components from laboratory as well as production environments. 1 O" X 12" deep (8.4" diameter when using parts basket) and (213mm X 305mm)

Performance Characteristics

PolyClean Model 26L:

| Temperature Range | 50 to 605°C |

|---|---|

| Overall footprint, H x W x D (inches) | 41 x 24 x 26 |

| Temperature Stability at 500°C | ±1.5 ºC |

| Calibrated Accuracy at 500º C | ±10.0 ºC |

| Radial Temperature Uniformity at 500ºC | 3.0 |

| Heat Up time: Ambient to 600ºC | 180 minutes |

| Power Consumption | 6.2 Kw (240v, single phase) |

| Working diameter | 9.5 inches |

| Working depth | 28 inches |

| Working area in basket (diam x depth) | 8.4 x 26 |

| Maximum load capacity | 52 lbs |

| Air pressure required | 40 PSI |

| Maximum Air consumption | 3.5 SCFM |

| Total Unit Weight | 160 lbs |

| Operating Weight with Aluminum Oxide | 360lbs |

| Cleaning Capacity | 50 lbs |

| Cool Downtime: Max to 200ºC | 210 minutes |

Material Burn Off Temp Guide

| • Nylon 450°C/842° F • Paint 475-575°C/887-1067° F • Styrene 450°C/842° F • Polyethylene 425-450°C/797-842° F • Polypropylene 425-500°C/797-932° F • Flouropolymers 525°C/975° F • PTFE 500°C/932° F • PVC 460-540°C/860-1004° F • High density polythene 450°C/842° F • PEEK 500-525°C/932-977° F • Silicone Rubber 535°C/995° F • Polyesters 450°C/842° |

• Ethylene methacytic 450-480°C/842-8960F • Polyurethane 440-450°C/824-842° F • Polystyrene 450° C/842° F • Rubber debonding 350°C/662° F • Polycarbonate 400-425°C/752-797 ° F • Organic matter oil/grease 300-5000C/572-932 ° F • Crosslink PE 400°C/750° F |

|---|

Certification Approval

|

EU Declaration of Conformity |

|

ISO 9001:2015 |

|

EAC - The Eurasian Conformity mark |

|

RoHS Compliance Fact Sheet |