MDT 435

The MDT series signal amplifiers convert the process pressure into an amplified signal for long-distance transmission without interference. All models are available in 4-20 mA, 0-5 VDC and 0-10 VDC, 2-, 3- and 4-wire variants. Many of the features found in the standard Dynisco MDA series have been incorporated into the enhanced MDT series, including the proven strain gauge sensor design for stable operation, including the flexible capillary design. The sensors have an internal digital calibration.

All sensors in this series can be configured according to your needs. Contact us, we will be happy to help you.

Melt pressure sensor in design with exposed capillary

Melt pressure sensor in design with exposed capillary

Sensor terminal and compatible cable connector

Detail - screw cable connector Amphenol 8-PIN

Inquiry system

Configure your own product according to your requirements and needs. If you are unsure of the configuration, provide us in the notes the necessary information about the existing sensor or product, even a competitor. We will be happy to help you find an alternative Dynisco product. If your request is urgent, let us know. We will do our best to help you resolve this situation to your satisfaction as quickly as possible. If we have all the information, we are able to offer a model with minor differences, which is in stock and you can have another product available the next day.

If you need more information do not hesitate to contact us.

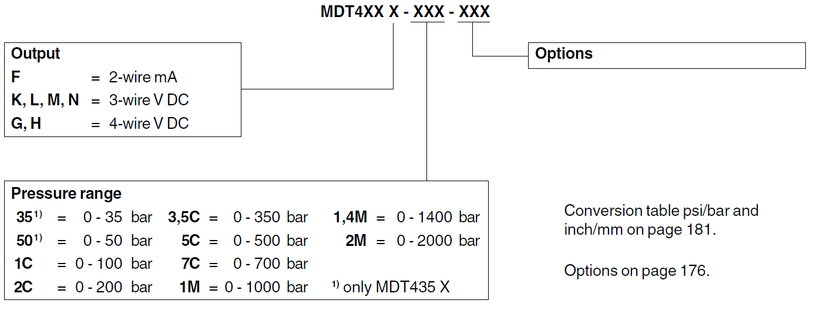

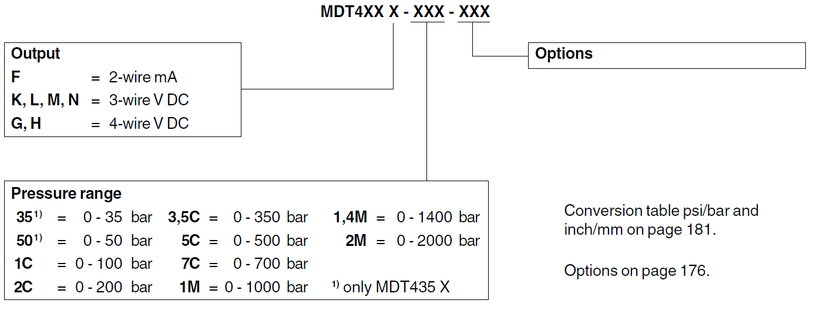

Dynisco configuration code:

High Accuracy, Simple Installation, Repeatability And Reliability

Dyniscos MDT-series amplified transducers convert process pressure into an amplified signal for long distance transmission free of noise interference.

MDT435 Pressure Sensors - With flexible and exposed capillary

Innovative pressure sensor, perfectly designed for injection applications with minimal installation space. Thanks to its unique features and state-of-the-art technical parameters, this sensor can cope with demanding conditions in any environment. The manufacturer spared no expense in advanced technologies and sophisticated production processes, enabling the sensor to achieve very small dimensions and low weight without any compromise to its outstanding performance. The pressure sensor is an ideal solution for a wide range of injection applications, thanks to its exceptional resistance to vibrations, which it can withstand very well. A pleasant bonus is the easy and hassle-free installation of this sensor in spaces with limited dimensions.

Innovative pressure sensor, perfectly designed for injection applications with minimal installation space. Thanks to its unique features and state-of-the-art technical parameters, this sensor can cope with demanding conditions in any environment. The manufacturer spared no expense in advanced technologies and sophisticated production processes, enabling the sensor to achieve very small dimensions and low weight without any compromise to its outstanding performance. The pressure sensor is an ideal solution for a wide range of injection applications, thanks to its exceptional resistance to vibrations, which it can withstand very well. A pleasant bonus is the easy and hassle-free installation of this sensor in spaces with limited dimensions.

All models are available in 4-20 mA, 0-5 VDC and 0-10 VDC, 2-, 3- and 4-wire high level outputs. Many of the features found in Dynisco's standard MDA-series have been incorporated into the amplified MDT-series, including proven bonded strain gauge construction for stable operation, a flexible armored capillary between the rigid stem and the amplifier housing and a flush diaphragm. Another advantage is the electrical built-in calibration.

⚠ WARNING: This product can expose you to chemicals including mercury and lead, which is known to the State of California to cause cancer and reproductive harm. For more information, go to www.P65Warnings.ca.gov.

Electrical Characteristics

| Configuration: |

Four-arm Wheatstone bridge strain gage (DMS) |

| Internal Shunt-Calibration: |

80% of full scale ±5% |

| Leakage Resistance: |

1000 MΩ at 50 V DC |

MDT4XXF

|

2-wire mA

|

| Output Signal: |

4-20 mA |

| Supply Voltage: |

10-36 V DC |

| Zero Balance: |

2% ±5% of full scale adjustable |

| Load Resistance: |

Maximum 1.2Ω at 36 V |

MDT4XX K / L / M / N

|

3-wire V DC

|

| Output Signal: |

K: 0-5 V DC, M: 1-6 V DC

L: 0-10 V DC, N: 1-11 V DC |

| Supply Voltage: |

15-32 V DC |

| Load Resistance: |

K: >5 kΩ, M: >5 kΩ,

L: >10 kΩ, N: >10 kΩ |

MDT4XX G / H

|

4-wire V DC

|

| Output Signal: |

G: 0-5 V DC

H: 0-10 V DC |

| Supply Voltage: |

dual ±10 to ±16 V DC

single 19-32 V DC |

| Load Resistance: |

G: >5 kΩ, H: >10 kΩ |

Temperature Characteristics

Diaphragm

|

|

| Max. Temperature: |

400°C |

| Zero Shift (due to temperature change): |

< 0.2 bar / 10 °C |

Housing

|

|

| Max. Temperature: |

85ºC |

| Zero Shift (due to temperature change): |

±0.2% f.s.v./10°C |

| Sensitivity Shift (due to temperature change): |

±0.1% f.s.v./10 °C -up to 50 bar ± 0.2% f.s.v./10 °C |

Technical Data and Operating Characteristics

| Pressure Range: |

0 - 17 bar to 0 - 2000 bar |

| Accuracy: |

± 0.5 % f.s.v. - up to 50 bar ± 1 % f.s.v. |

| Repeatability: |

± 0.1 % f.s.v. - up to 50 bar ± 0.2 % f.s.v. |

| Resolution: |

infinite |

Maximum Overload

(without influencing operating data): |

2 x pressure range for range 1000 and 1400 bar max. 1750 bar and max. 2400 bar for range 2000 bar |

| Burst Pressure: |

6 x pressure range max. 3000 bar |

| Material in Contact with Media: |

15-5 Mat. No. 1.4545, DyMAX coated |

Ordering Guide for MDT435 Series

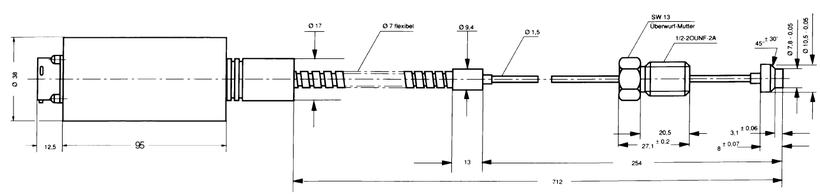

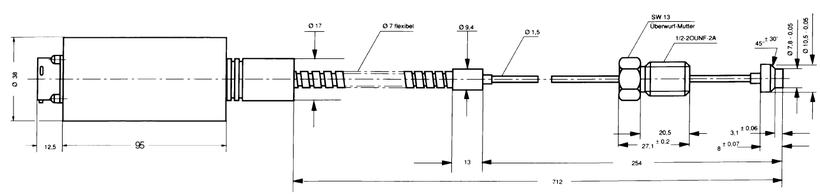

MDT435 - Dimensions

All dimensions are inches (mm) unless otherwise specified.

Installation of transducers into improperly cleaned or sized holes is one of the major causes of damage to these instruments. With this kit, the .312" tip diameter hole, the 45 degree seating surface, and the .451" hole can be cleaned. The kit includes a gauging plug which is used to verify that the hole has been correctly machined and cleaned. M10 and M18 cleaning kits also available.

The Dynisco Transducer Mounting Hole Machining Tool Kit contains all of the necessary drills and taps to prepare a standard 1/2 - 20 UNF transducer mounting hole and the 45 degree seat. All tools included in this kit are made of premium grade, high strength tool steel. Care should be taken in the use of proper speeds and feeds, lubricants, and a method to assure continual alignment of each progressing tool. M10 and M18 kits are also available.

1480 is a universal pressure or temperature indicator with one or double configurable alarm as well as optional linear retransmission of the displayed process. Ideal for use in extrusion applications.

Indicator 1490 is a universal device with one or two configurable alarms, optional linear process variable retransmission, optional pressure sensor power supply, and optional Modbus communication.

The Dynisco UPR900 is a compact 1/4 DIN process indicator. The UPR900 can display your preferred production process values. Optional secondary input for displaying the temperature or pressure of the polymer melt all in one place. The secondary input can be a strain gauge to measure the differential pressure in the process. The UPR900 contains two standard assigned alarms with the option to add a third alarm.

The ATC 990 series controller is a time-tested product that has received a new design and new functions. Compared to classic features such as pressure, temperature and alarm setting options, these new models are enhanced with the ability to monitor and record parameters to a USB drive, the undeniable advantage is the large display and interactive environment when setting up the controller.

These cables are used to connect Dynisco pressure sensors to a 6-pin connector. The cables provide the electrical connection between the sensors and the indicators or controllers. The kits consist of a Bendix bayonet connector and a six-core shielded cable.

Separate Bendix connectors. In the variant of the 6-pin connector.

Certifikati in odobritve

Pregled razpoložljivih certifikatov in odobritev: Obiščite to povezavo, ki vas bo odpeljala na stran s celovitim seznamom trenutnih certifikatov in odobritev za naše izdelke. Tu lahko preverite, ali naša ponudba ustreza najvišjim standardom kakovosti in varnosti. Več informacij

Pregled razpoložljivih certifikatov in odobritev: Obiščite to povezavo, ki vas bo odpeljala na stran s celovitim seznamom trenutnih certifikatov in odobritev za naše izdelke. Tu lahko preverite, ali naša ponudba ustreza najvišjim standardom kakovosti in varnosti. Več informacij

Odkrijte svet naše spletne strani za e-učenje in spoznajte, kako poenostaviti vašo vsakodnevno uporabo naših izdelkov. Naše praktične in celovite tečaje ter informativne materiale vam bodo pokazali, kako poenostaviti in izboljšati uporabo naših tehnologij, razkriti nove informacije in tehnike ter optimizirati delovne procese. S temi viri boste dosegli večjo učinkovitost, prihranili čas in izboljšali rezultate vašega dela. Več informacij

Odkrijte svet naše spletne strani za e-učenje in spoznajte, kako poenostaviti vašo vsakodnevno uporabo naših izdelkov. Naše praktične in celovite tečaje ter informativne materiale vam bodo pokazali, kako poenostaviti in izboljšati uporabo naših tehnologij, razkriti nove informacije in tehnike ter optimizirati delovne procese. S temi viri boste dosegli večjo učinkovitost, prihranili čas in izboljšali rezultate vašega dela. Več informacij

Naši instrukcijski video posnetki ponujajo interaktiven način učenja o naših izdelkih. Združujejo vizualno in zvočno vsebino ter ponujajo praktične rešitve za pogoste težave, s čimer prihranite čas in se izognete morebitnim težavam. Če naletite na težavo, vam naši video priročniki ponujajo podrobna navodila in praktične nasvete za njeno reševanje. Na voljo so kadarkoli in predstavljajo priročen vir informacij, ki dopolnjuje našo tehnično podporo. Več informacij

Naši instrukcijski video posnetki ponujajo interaktiven način učenja o naših izdelkih. Združujejo vizualno in zvočno vsebino ter ponujajo praktične rešitve za pogoste težave, s čimer prihranite čas in se izognete morebitnim težavam. Če naletite na težavo, vam naši video priročniki ponujajo podrobna navodila in praktične nasvete za njeno reševanje. Na voljo so kadarkoli in predstavljajo priročen vir informacij, ki dopolnjuje našo tehnično podporo. Več informacij

Naši tehnični članki nudijo praktičen način za spoznavanje več o naših izdelkih in njihovi uporabi. Zagotavljajo podrobne informacije in praktične nasvete o reševanju pogostih težav, s čimer prihranite čas in se izognete morebitnim težavam. Če še vedno naletite na težavo, naši tehnični članki ponujajo posebna navodila za njeno reševanje. Na voljo so kadarkoli in predstavljajo priročen vir informacij, ki dopolnjuje našo tehnično podporo. Več informacij

Naši tehnični članki nudijo praktičen način za spoznavanje več o naših izdelkih in njihovi uporabi. Zagotavljajo podrobne informacije in praktične nasvete o reševanju pogostih težav, s čimer prihranite čas in se izognete morebitnim težavam. Če še vedno naletite na težavo, naši tehnični članki ponujajo posebna navodila za njeno reševanje. Na voljo so kadarkoli in predstavljajo priročen vir informacij, ki dopolnjuje našo tehnično podporo. Več informacij