Local and remote rezeroing capability

Our pressure sensors offer efficient, accurate, and durable solutions for reliable and safe pressure measurement. These sensors are used in a variety of industrial areas, where they monitor and measure the pressure of molten materials, ensuring optimal operation of production processes. Due to their resistance to high temperatures and pressures, which are typical for these applications, they represent a suitable choice for diverse uses. When selecting a sensor, it is important to consider the specific requirements of your application, such as temperature range, pressure range, and materials with which the sensor will interact. The correct choice of sensor guarantees reliable and accurate results and a long service life of the device without any problems. Installing the sensor into the mounting hole of the production line is simple.

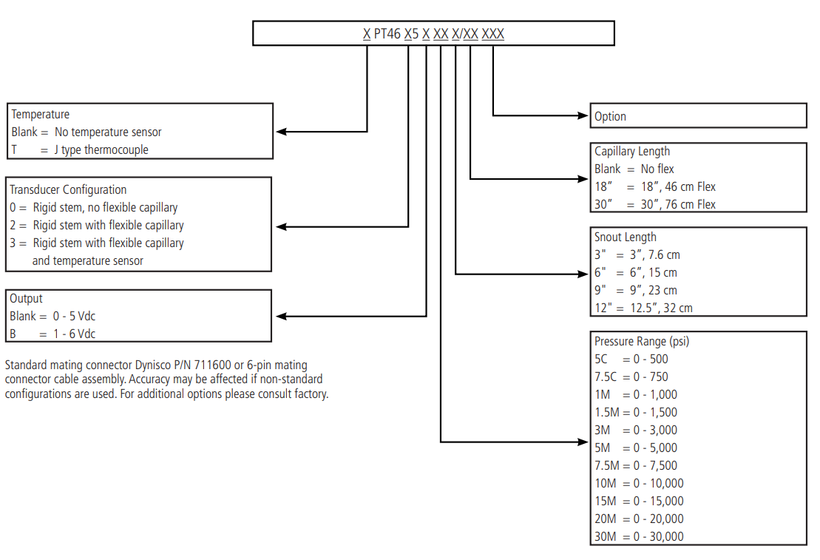

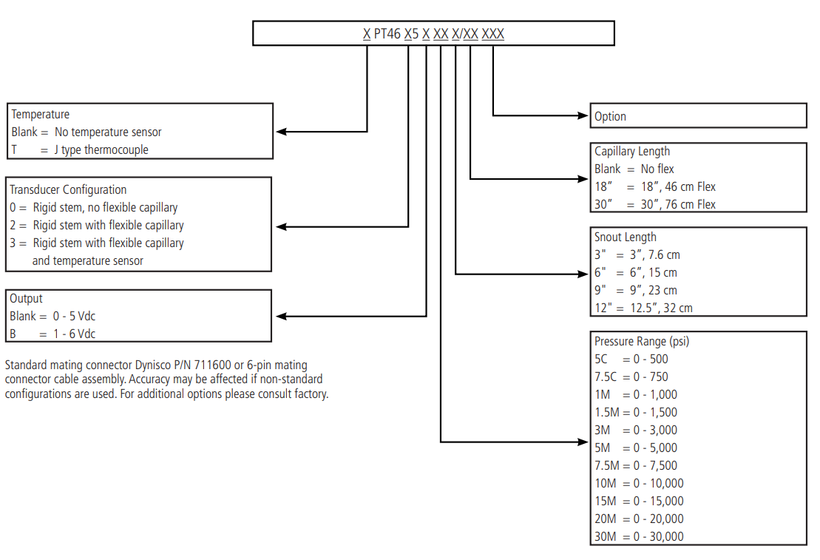

The PT46X5 Series transmitter is a +/- 0.5% sensor ideal for general purpose melt pressure measurements requiring simple installation, repeatability and reliability. The PT46X5 transmitters provide the industry standard 0 - 5 Vdc amplified signal designed to work with DCS and PLCs, 1 - 6 Vdc outputs are also available. The PT46X5 comes equipped with zero and span pots to adapt the transmitter to process conditions. Optional thermocouple or RTD configurations are available to provide melt temperature. The PT46X5 features a 1/2-20 UNF thread for installation in standard transducer mounting holes and can be supplied with a variety of electrical connections.

The PT46X5 Series includes models PT4605, PT4625, PT4635, TPT4605, TPT4625, and TPT4635.

⚠ WARNING: This product can expose you to chemicals including mercury and lead, which is known to the State of California to cause cancer and reproductive harm. For more information, go to www.P65Warnings.ca.gov.

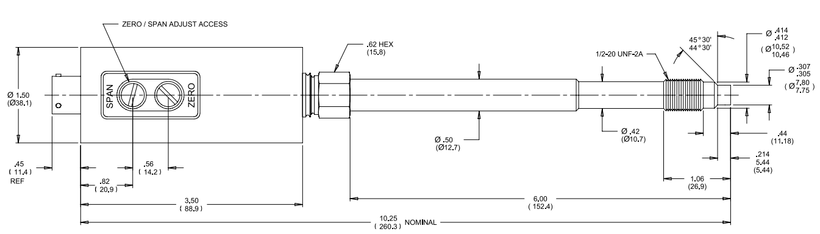

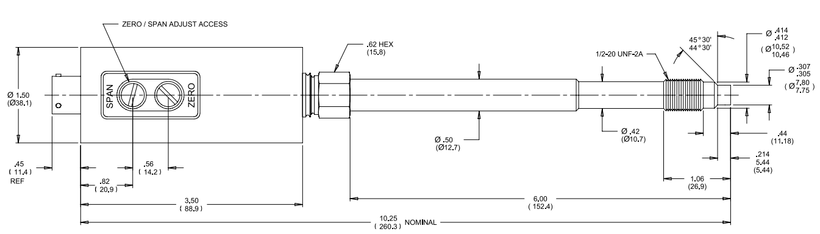

PT4605 Pressure Sensors - With rigid stem

Rigid Stem pressure sensors are easily installed into the mounting hole of the production line, ensuring a simple and robust design that is suitable for applications where the sensor is not exposed to radiant heat from the line and the electronics are not subjected to extreme temperatures. We do not recommend installing these sensors in a vertical position above the line (12 o'clock position), as radiant heat can negatively affect the sensor's electronics lifespan. In such cases, we recommend using a sensor design with a flexible capillary, which allows the electronics to be diverted away from the radiant heat, ensuring a long sensor life. The main advantages of this type of sensor include resistance to impacts and vibrations, enabling them to withstand mechanical stress, which increases their lifespan and reduces the need for maintenance. They also feature high accuracy, ensured by quality materials and advanced measurement technology, which is crucial for efficient process control.

Rigid Stem pressure sensors are easily installed into the mounting hole of the production line, ensuring a simple and robust design that is suitable for applications where the sensor is not exposed to radiant heat from the line and the electronics are not subjected to extreme temperatures. We do not recommend installing these sensors in a vertical position above the line (12 o'clock position), as radiant heat can negatively affect the sensor's electronics lifespan. In such cases, we recommend using a sensor design with a flexible capillary, which allows the electronics to be diverted away from the radiant heat, ensuring a long sensor life. The main advantages of this type of sensor include resistance to impacts and vibrations, enabling them to withstand mechanical stress, which increases their lifespan and reduces the need for maintenance. They also feature high accuracy, ensured by quality materials and advanced measurement technology, which is crucial for efficient process control.

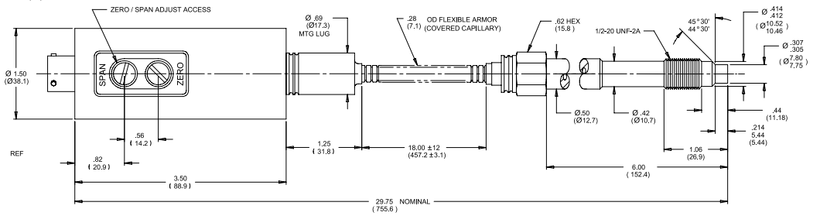

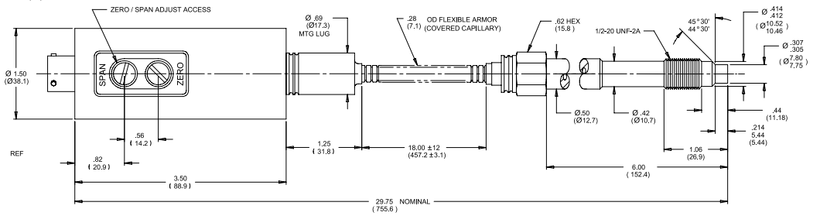

PT4625 Pressure Sensors - With rigid stem and flexible capillary

Pressure sensors with flexible capillaries represent a professional solution suitable for applications with limited space or exposure to radiant heat from heating elements in production lines. Thanks to the thoughtful extended design, the sensor's electronics are located out of reach of the radiant heat source, reducing the risk of damage.

The flexible capillary is designed to be resistant to damage and allow a high degree of bending, which facilitates installation and handling of the sensor. It is essential to properly secure the sensor head to the included adapter, which is part of the package. To achieve optimal performance, we recommend placing the adapter on a part of the machine where unwanted vibrations or shocks do not occur, as these could negatively affect the sensor.

The length of the rod and flexible capillary can be customized according to individual needs, as well as other optional components. This ensures maximum flexibility in integrating the sensor into a wide range of industrial applications.

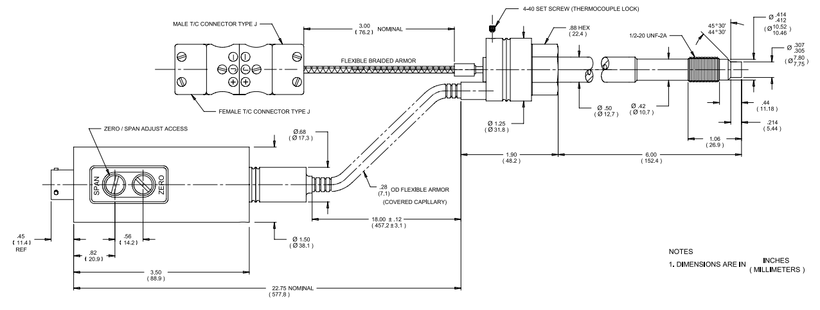

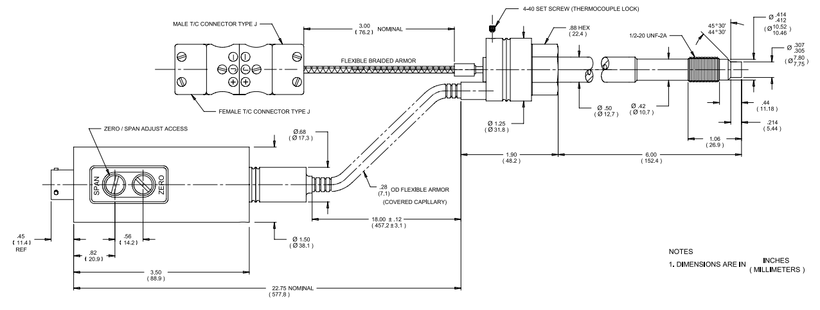

TPT4635 Pressure Sensors - Combined sensor with rigid stem, flexible capillary and built-in temperature sensor

Combined pressure sensors with flexible capillaries represent a professional solution suitable for applications with limited space or exposure to radiant heat from heating elements in production lines. Thanks to the thoughtful extended design, the sensor's electronics are located out of reach of the radiant heat source, reducing the risk of damage.

Additionally, these sensors are equipped with a temperature sensor, allowing the customer to choose the type of sensor, whether it is a type J, K thermocouple, or an RTD (pt100). By selecting a compatible sensor for temperature measurement, the customer obtains information about the melt temperature from a single process connection, increasing measurement efficiency and accuracy.

The flexible capillary is designed to be resistant to damage and allow a high degree of bending, which facilitates installation and handling of the sensor. It is essential to properly secure the sensor head to the included adapter, which is part of the package. To achieve optimal performance, we recommend placing the adapter on a part of the machine where unwanted vibrations or shocks do not occur, as these could negatively affect the sensor.

The length of the rod and flexible capillary can be customized according to individual needs, as well as other optional components. This ensures maximum flexibility in integrating the sensor into a wide range of industrial applications.

Performance Characteristics

Outputs:

|

|

| PT46X5: |

0 - 5 Vdc |

| PT46X5B: |

1 - 6 Vdc |

| Input Voltage: |

11 - 36 Vdc |

| Accuracy: |

±0.5% FSO combined error (Including Linearity, Repeatability & Hysteresis) |

| Repeatability: |

±0.2% FSO |

| Configuration: |

Four-arm bonded foil Wheatstone bridge strain gage |

| Load Resistance: |

2,000 Ohms minimum |

| Over Pressure: |

2X FSO or 35,000 psi, (whichever is less) |

| Zero Balance Adjustment Range: |

±15% |

| Span Adjustment Range: |

±15% |

| Internal Shunt Calibration (R-Cal): |

80% FSO ±0.5% |

Temperature & Mechanical Characteristics

| Max Diaphragm Temperature: |

750°F (400°C) |

| Zero Shift (due to temperature change): |

25 psi/100°F Typical (45 psi/100°C) |

| Electronics Operating Temperature: |

-20° to 185°F (-29° to 85°C) |

| Zero Shift (due to temperature change): |

± 0.05% FS/°F max (± 0.10% FS/°C max) |

| Span Shift (due to temperature change): |

± 0.02% FS/°F max (± 0.04% FS/°C max |

| Mounting Torque: |

500 inch/lbs. max |

| Standard Wetted Parts: |

Dymax® coated 15-5 PH SST |

Ordering Guide for PT46x5 Series

PT4605 - Dimensions

All dimensions are inches (mm) unless otherwise specified.

PT4625 - Dimensions

All dimensions are inches (mm) unless otherwise specified.

TPT4635 - Dimensions

All dimensions are inches (mm) unless otherwise specified.