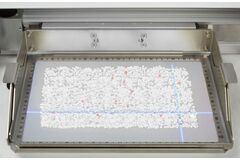

PURITY CONCEPT V is an innovative optical offline inspection system by SIKORA, designed for fast and automated quality control of transparent pellets and flakes. It reliably detects and analyses contamination and defects such as black specks, color deviations, or yellow discoloration. Thanks to its modular design concept, the system can also be configured for inspection of transparent films and tapes.

News: SIKORA PURITY CONCEPT V – optical offline inspection for contamination in pellets and flakes

PURITY CONCEPT V is an innovative optical offline inspection system by SIKORA, designed for fast and automated quality control of transparent pellets and flakes. It reliably detects and analyses contamination and defects such as black specks, color deviations, or yellow discoloration. Thanks to its modular design concept, the system can also be configured for inspection of transparent films and tapes.

Key benefits of PURITY CONCEPT V

Why choose PURITY CONCEPT V

Contamination and optical defects often become visible only in the final product – causing visible imperfections, color deviations, or reduced process stability. PURITY CONCEPT V enables fast and objective quality inspection before releasing material to production or shipping it to customers.

Typical applications

Want to verify the quality of your pellets or flakes?

We will be happy to review your application and recommend the right PURITY CONCEPT V configuration for your materials and requirements.

Contact us for an individual offer