ViscoIndicator

Designed specifically for the thermoplastics industry, the ViscoIndicator provides continuous melt flow, apparent or intrinsic viscosity measurements directly on the production line.

The ViscoIndicator online rheometer duplicates the test conditions of a laboratory Melt Flow Rate (MFR) tester or capillary rheometer. Melt viscosity measurements such as melt flow rate and Intrinsic viscosity are primary specifications of thermoplastic resins. MFR and melt viscosity are related to polymer molecular properties so these numbers give some measure of the physical properties of their product as well as polymer processability. The ViscoIndicator has a look and feel that will be familiar to most shop personnel.

Why is this important – it lowers the training time to become effective in measuring the rheological properties of your polymer process. This along with the ease of connection gets you up in running in the minimal amount of time.

ViscoIndicator - Measurement of rheological parameters in real time.

ViscoIndicator - Measurement of rheological parameters in real time.

ViscoIndicator - Measurement of rheological parameters in real time.

ViscoIndicator - Measurement of rheological parameters in real time.

ViscoIndicator - Measurement of rheological parameters in real time.

ViscoIndicator - Measurement of rheological parameters in real time.

ViscoIndicator - Measurement of rheological parameters in real time.

ViscoIndicator - Measurement of rheological parameters in real time.

Inquiry System

Configure your own device, according to your requirements and needs. If you are not sure about the configuration, make the necessary information about the processed materials in the notes. Thanks to this information, we are able to create several offers depending on the equipment and after the consultation, you can choose according to your needs. If you need a comparison for tenders, we will be happy to help you find an alternative product from Dynisco products.

If you need more information do not hesitate to contact us.

Configuration code

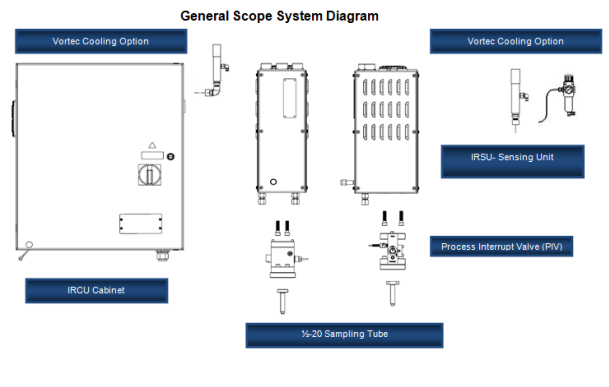

THE VISCOINDICATOR RSU

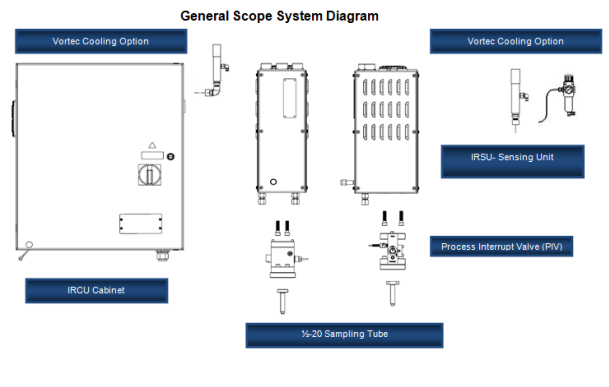

A Rheological Sensing Unit (RSU) that connects directly to the process and samples, conditions, and measures the properties of the resin. It can be mounted on extruders, reactors, or molten polymer transfer lines in various orientations. It uses a metering pump to isolate it from the process, to di-rect the molten polymer across interchangeable capillaries, and discharge a minimal amount of material at a rate of approximately 0.5lb/hr (0.2kg/hr). A three wire platinum RTD is used to control and measure the tem-perature of the molten polymer. A Vertex Mercury Free pressure transducer mounted directly before the capillary die is used to capture the pressure drop.

VISCOINDICATOR HUMAN MACHINE INTERFACE

The Human Machine Interface (HMI) remotely manages test parameters and provides measured and computed material properties. It provides rheologi-cal data similar to a Laboratory Capillary Rheometer or MFR readings similar to a Melt Flow Indexer.

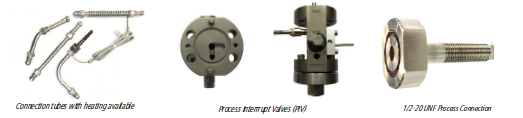

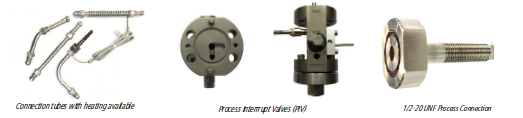

Optional Process Adapters for Easy Mounting

Allow us to customize the connection to a customer's specific needs

VISCOINDICATOR iRCU

A Rheological Control Unit (iRCU) that controls the measurement parameters (temperature, pressure, flow rate), and provides communications to an HMI. This combination provides the system with processing power and hi-end graphics allowing the iRCU to provide +/- 2% Full Scale Accuracy. Th iRCU provides the processor the ability to measure Melt Flow Ratio, Relative Viscosity, Intrinsic Viscosity, and Melt Viscosity in typical end-user environments. All of which create a cost-effective system that reduces the risk of failure to an acceptable level. The ViscoIndicator controls are based on an industry standard Windows 10 IoT. External connectivity can be accomplished through Ethernet, Wireless Connection to Windows 10 computers, or USB. A color touch screen, local human-machine interface (HMI) is standard. The HMI allows for the calibration and configuration of the system and is typically housed in a separate enclosure located within a distance of 10 meters from the iRCU, with an interconnecting cable.

Performance Characteristics

| Melt Flow Index Range |

0.1 to 25,000 g/10min

(With Melt Density of 0.75g/cc and 2.16Kg test load) |

| Viscosity Range |

10 – 105 Pa.S (Applicable Shear Rates Vary with Viscosity) |

| Intrinsic Viscosity Range |

0.2-5.0 |

| Shear Rate |

0.1 to 25,000 sec-1 |

| Shear Stress |

2.9 x 103 – 1.95 x 105 Pa |

| Temperature Range |

40 – 350°C |

| Pressure Range |

3 x 105 – 3.5 x 107 Pa |

| Max Process Temperature |

350°C |

| Material Geneaology Output |

Provides full lot traceabilty of rheological data from start to finish of your process. Data is available real time via HMI (running number or historical trend graph), with ability to export historical data via CSV file

|

| Pump Speed Range |

1 to 60 RPM

Brushless Servo motor with resolver feedback |

Physical Dimensions

| ViscoIndicator RSU (HxWxD): |

20" x 6" x 8 " (508mm x 152mm x 203mm) |

| ViscoIndicator IRCU (HxWxD): |

24” x 12”x 8” (610mm x 305mm x 203mm) |

| ViscoIndicator HMI Screen (LxH): |

7" diagonal: 6.2" x 3.5" (157.5mm x 89mm) |

Electrical Specifications

| System Voltage |

220-240 VAC, single phase, 50/60 Hz-standard1 |

| Power Requirements |

1,500 W |

| Maximum Distance from iRCU to Rheometer Sensing Unit (RSU): |

Standard cable: 2.5" (up to 100m available)

The interconnecting cables required for the ViscoIndicator for longer distances are included in the options and accessories section of this quotation.

NOTE: Maximum distance between the HMI and the IRCU is 10 meters. |

| HMI/Display : |

NEMA 3, IP20 Enclosure1 |

External Connections

| Digital Output |

Fault and Warning (Dry Contact) |

| Digital Input |

Remote Start (24VDC) & Emergency Stop |

1 Consult factory for other options avaliable

Diagram

This LMFI5500 series Melt Flow Indexer allows the measurement of most rheological parameters of thermoplastics including IV for PET. The LMFI 5500 series is one of the most accurate equipment of the type in the world. The intuitive controls make it easy to use, it has an expert mode for experienced operators that significantly speeds up the measurement process, and sophisticated features and technologies ensure the highest possible measurement accuracy. Gravity correction and dual zone heating not only meet but exceed the requirements of the latest ISO1133-2 valid standard.

This model is perfect for quality control in a laboratory, institutes or universities where accuracy really matters. Try the LMFI 5500 and get a reliable and accurate instrument that will allow you to improve the quality of your products.

Introducing the LMI6000 series. The new generation of comfort and performance. The automated electromechanical lifting mechanism simplifies weight lifting. A larger, adjustable touch display allows for easy operation. Modernized hardware architecture ensures higher performance. Software automation enables one-button test initiation. The LMI6000 revolutionizes your work environment, combining comfort, efficiency, and reliability.

The new LCR 7000 Capillary Rheometer range offers a number of new features and meets the requirements of 24-hour operation while maintaining the highest possible accuracy, repeatability and sensitivity. The LCR series rheometers are versatile and easy to use, but offer the most complex methods for polymer characterization, data analysis and reporting capabilities. The LCR series can be used with a standard load cell and a pressure transducer mounted in the rheometer chamber.

Meets standards:

DIN ISO-11433, DIN-53014, DIN-54811, ASTM-D3835

The Dynisco Polymer Test LME Laboratory Mixing Extruder is a unique laboratory tool developed to evaluate the processability of a variety of plastics and rubbers prior to production. From very fine powders to coarse materials, the LME will meet many extruding needs. The LME possesses a movable header and dial gage that allows for constant mixer adjustability. While in operation, the rotational shearing (mixing) is controlled by adjusting the distance between the end of the rotor and the inside header.

The Dynisco MiniGran Lab Granulator is designed for the granulation of small sprues. With its very compact dimensions, this granulator can be accommodated almost anywhere and therefore is very suitable for laboratory applications. The granulator is suitable for all kind of plastic materials, due to the low rotor speed the plastic materials are processed to high-quality, low-dust regrind.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.