ViscoSensor

Specially designed for the thermoplastic polymers industry. ViscoSensor provides continuous measurement of melt flow index or apparent viscosity or intrinsic viscosity (IV) directly on the production line. The ViscoSensor system consists of two parts:

The Viscosensor RSU (Rheologic Sensing Unit) is directly connected to the process, where it samples and measures the polymer melt flow index, and either the RCU or e-RCU, which controls the viscosensor system, controls the process parameters temperature, pressure, speed, provides outputs for calculate the results and, if necessary, ensure communication with an external distributed control system.

ViscoSense - Measurement of rheological parameters in real time

ViscoSense - Measurement of rheological parameters in real time

ViscoSense - Measurement of rheological parameters in real time

ViscoSense - Measurement of rheological parameters in real time

ViscoSense - Measurement of rheological parameters in real time

ViscoSense - Measurement of rheological parameters in real time

ViscoSense - Measurement of rheological parameters in real time

ViscoSense - Measurement of rheological parameters in real time

ViscoSense - Measurement of rheological parameters in real time

ViscoSense - Measurement of rheological parameters in real time

Inquiry System

Configure your own device, according to your requirements and needs. If you are not sure about the configuration, make the necessary information about the processed materials in the notes. Thanks to this information, we are able to create several offers depending on the equipment and after the consultation, you can choose according to your needs. If you need a comparison for tenders, we will be happy to help you find an alternative product from Dynisco products.

If you need more information do not hesitate to contact us.

Configuration code

Online Rheological Measurement Experience the Benefits of Online Rheology Measurement

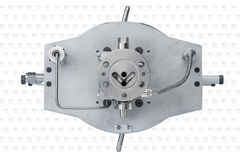

THE VISCOSENSOR RSU

The ViscoSensor employs a stacked pair of metering pumps to isolate it from the process, to direct the molten polymer across interchangeable capillaries, and to pump the molten polymer back into the process. A three wire platinum RTD is used to control and measure the temperature of the molten polymer. Two Dynisco Vertex Mercury Free pressure transducers (now comes standard) mounted directly before and after the die, are used to capture the pressure drop across the capillary.

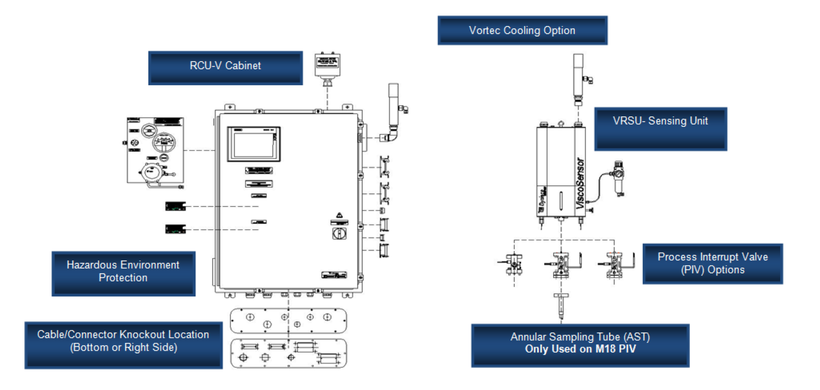

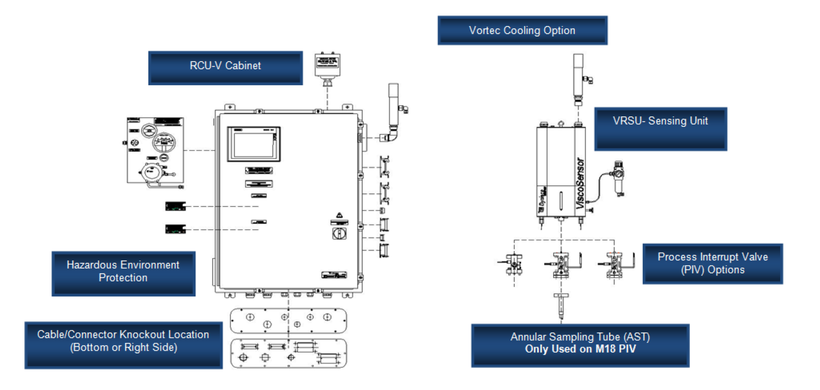

VISCOSENSOR RCU: ULTIMATE PERFORMANCE

Our high performance RCU combines the rheological properties of a Laboratory Capillary Rheometer with MFI readings delivered by a Melt Flow Indexer. It has been updated with a Siemens S7-1500 PLC with a Siemens 7” (178mm), Comfort Panel Touch Screen HMI. This combination provides increased processing pow-er and hi-end graphics enabling the RCU to provide +/- .5% Full Scale Accuracy. This allows the RCU to better align measurements with those taken from laboratory instruments. Furthermore, it is certified for hazardous environments as needed.

Our high performance RCU combines the rheological properties of a Laboratory Capillary Rheometer with MFI readings delivered by a Melt Flow Indexer. It has been updated with a Siemens S7-1500 PLC with a Siemens 7” (178mm), Comfort Panel Touch Screen HMI. This combination provides increased processing pow-er and hi-end graphics enabling the RCU to provide +/- .5% Full Scale Accuracy. This allows the RCU to better align measurements with those taken from laboratory instruments. Furthermore, it is certified for hazardous environments as needed.

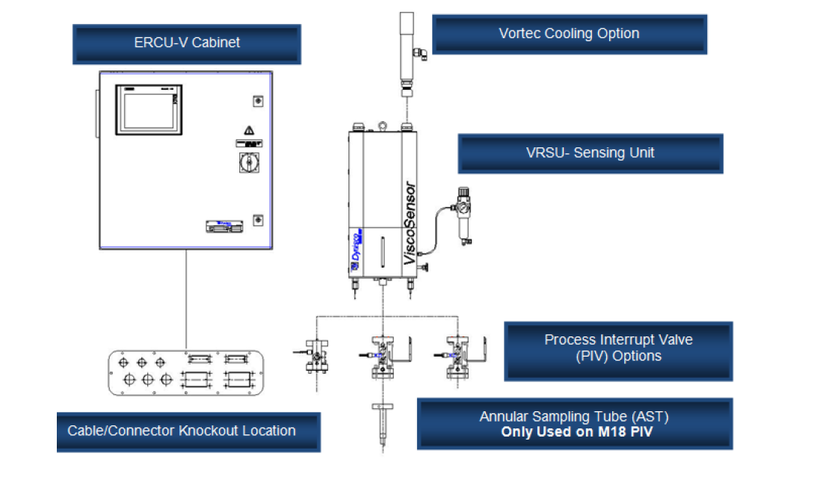

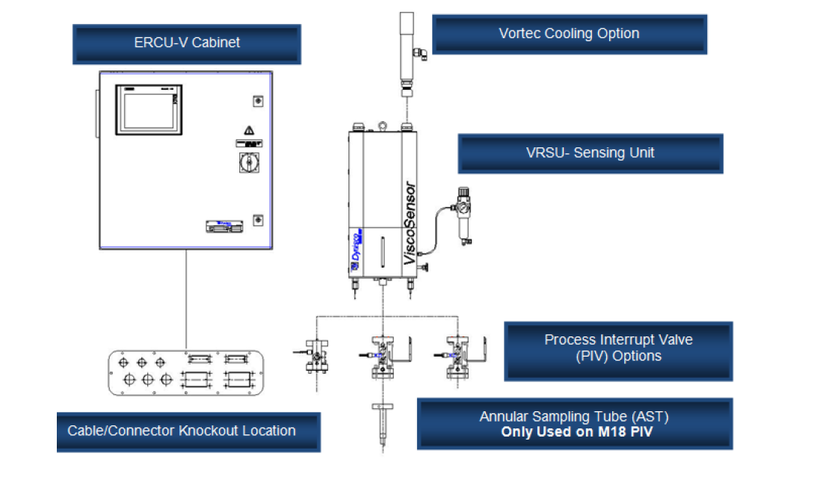

VISCOSENSOR e-RCU: PERFORMANCE SIMPLIFIED

The ViscoSensor e-RCU offers a simplified PLC with the digital and analog I/O that most plants would need for a cost effec-tive approach to measuring online rheology. It has a Siemens S7-1200 PLC with a Siemens 7” (178mm) Comfort Panel Touch Screen HMI. This combination provides the system with processing power and hi-end graphics allowing the e-RCU to provide +/- 2% Full Scale Accuracy. The e-RCU provides the processor the ability to measure Melt Flow Ratio, Relative Viscosity, Intrinsic Viscosity, and Melt Viscosity in typical end-user environments. All of which create a cost-effective system that reduces the risk of failure to an acceptable level. If conditions change and the system is needed in a hazardous and/or classified location, compatibility with the standard RCU allows for an easy upgrade.

PERFORMANCE CHARACTERISTICS

| Melt Flow Index |

0.1 - 25000 g/10 min |

| Viscosity Range |

10 – 105 Pas |

| Shear Stress |

150 - 1.5 x 105 Pa |

| Shear Rate |

0.1 – 7500 s-1 (standard die) max 50,000 s-1 (special die) |

| Dies |

|

| Temp. Range |

40 – 350°C |

|

Pressure Range

|

3 x 105 – 3.5 x 107 Pa |

| Metering Pump |

0.16 cm3 / RPM (standard)

0.297 cm3/ RPM (optional)

0.584 cm3/ RPM (optional)

|

| Pump Speed |

3 – 75 RPM |

| Polymer Flow |

225 g/hour (average) |

MEASUREMENT AND CONTROL FUNCTIONS

| Test Modes |

|

| Shear Stress Mode |

| Set point |

Pressure |

| Measurement |

Melt Flow Index |

| Shear Rate Mode |

| Set point |

Pump Speed |

| Measurement |

Apparent Viscosity |

| Temperature Control |

3 Heating Zones |

ANALOG OUTPUTS: (4 – 20 MA STANDARD)

| Options |

• Melt Flow Index

• Apparent Viscosity

• Melt Temperature

• Melt Pressure

• Pump Speed

• Temp. Pump Zone

• Temp. Die Zone |

Select any 2 of the following:

• Melt Pressure

• Delta-Pressure

• Melt Flow Index

• Apparent/Intrinsic Viscosity

|

ELECTRICAL SPECIFICATION

| System Voltage |

220-240V Single Phase, 50/60 Hz |

| Power |

2000 W (max) |

DIGITAL INPUTS

| Weight |

45 lbs. |

| Height |

25 in. (63.6 cm) |

| Width |

11.1 in. (28.2 cm) |

| Depth |

9.9 in. (25.2 cm) |

| Mounting Configuration |

Vertical (Stand for horizontal- only if using M18 pressure port) |

RHEOLOGIC CONTROL UNIT SPECIFICATIONS

|

RCU

|

E-RCU

|

| Electrical Cabinet |

NEMA 4, 4x, 12 (IP66) |

NEMA 4, (IP61) |

| CPU: |

Siemens 1500 Series |

Siemens 1200 Series |

| Operator Interface |

HMI, Siemens Comfort Panel |

HMI, Siemens Comfort Panel |

| Weight |

275 lbs |

80 lbs |

RCU

E-RCU

This LMFI5500 series Melt Flow Indexer allows the measurement of most rheological parameters of thermoplastics including IV for PET. The LMFI 5500 series is one of the most accurate equipment of the type in the world. The intuitive controls make it easy to use, it has an expert mode for experienced operators that significantly speeds up the measurement process, and sophisticated features and technologies ensure the highest possible measurement accuracy. Gravity correction and dual zone heating not only meet but exceed the requirements of the latest ISO1133-2 valid standard.

This model is perfect for quality control in a laboratory, institutes or universities where accuracy really matters. Try the LMFI 5500 and get a reliable and accurate instrument that will allow you to improve the quality of your products.

Introducing the LMI6000 series. The new generation of comfort and performance. The automated electromechanical lifting mechanism simplifies weight lifting. A larger, adjustable touch display allows for easy operation. Modernized hardware architecture ensures higher performance. Software automation enables one-button test initiation. The LMI6000 revolutionizes your work environment, combining comfort, efficiency, and reliability.

The new LCR 7000 Capillary Rheometer range offers a number of new features and meets the requirements of 24-hour operation while maintaining the highest possible accuracy, repeatability and sensitivity. The LCR series rheometers are versatile and easy to use, but offer the most complex methods for polymer characterization, data analysis and reporting capabilities. The LCR series can be used with a standard load cell and a pressure transducer mounted in the rheometer chamber.

Meets standards:

DIN ISO-11433, DIN-53014, DIN-54811, ASTM-D3835

The Dynisco MiniGran Lab Granulator is designed for the granulation of small sprues. With its very compact dimensions, this granulator can be accommodated almost anywhere and therefore is very suitable for laboratory applications. The granulator is suitable for all kind of plastic materials, due to the low rotor speed the plastic materials are processed to high-quality, low-dust regrind.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.

The ViscoSensor employs a stacked pair of metering pumps to isolate it from the process, to direct the molten polymer across interchangeable capillaries, and to pump the molten polymer back into the process. A three wire platinum RTD is used to control and measure the temperature of the molten polymer. Two Dynisco Vertex Mercury Free pressure transducers (now comes standard) mounted directly before and after the die, are used to capture the pressure drop across the capillary.

The ViscoSensor employs a stacked pair of metering pumps to isolate it from the process, to direct the molten polymer across interchangeable capillaries, and to pump the molten polymer back into the process. A three wire platinum RTD is used to control and measure the temperature of the molten polymer. Two Dynisco Vertex Mercury Free pressure transducers (now comes standard) mounted directly before and after the die, are used to capture the pressure drop across the capillary.

Our high performance RCU combines the rheological properties of a Laboratory Capillary Rheometer with MFI readings delivered by a Melt Flow Indexer. It has been updated with a Siemens S7-1500 PLC with a Siemens 7” (178mm), Comfort Panel Touch Screen HMI. This combination provides increased processing pow-er and hi-end graphics enabling the RCU to provide +/- .5% Full Scale Accuracy. This allows the RCU to better align measurements with those taken from laboratory instruments. Furthermore, it is certified for hazardous environments as needed.

Our high performance RCU combines the rheological properties of a Laboratory Capillary Rheometer with MFI readings delivered by a Melt Flow Indexer. It has been updated with a Siemens S7-1500 PLC with a Siemens 7” (178mm), Comfort Panel Touch Screen HMI. This combination provides increased processing pow-er and hi-end graphics enabling the RCU to provide +/- .5% Full Scale Accuracy. This allows the RCU to better align measurements with those taken from laboratory instruments. Furthermore, it is certified for hazardous environments as needed.