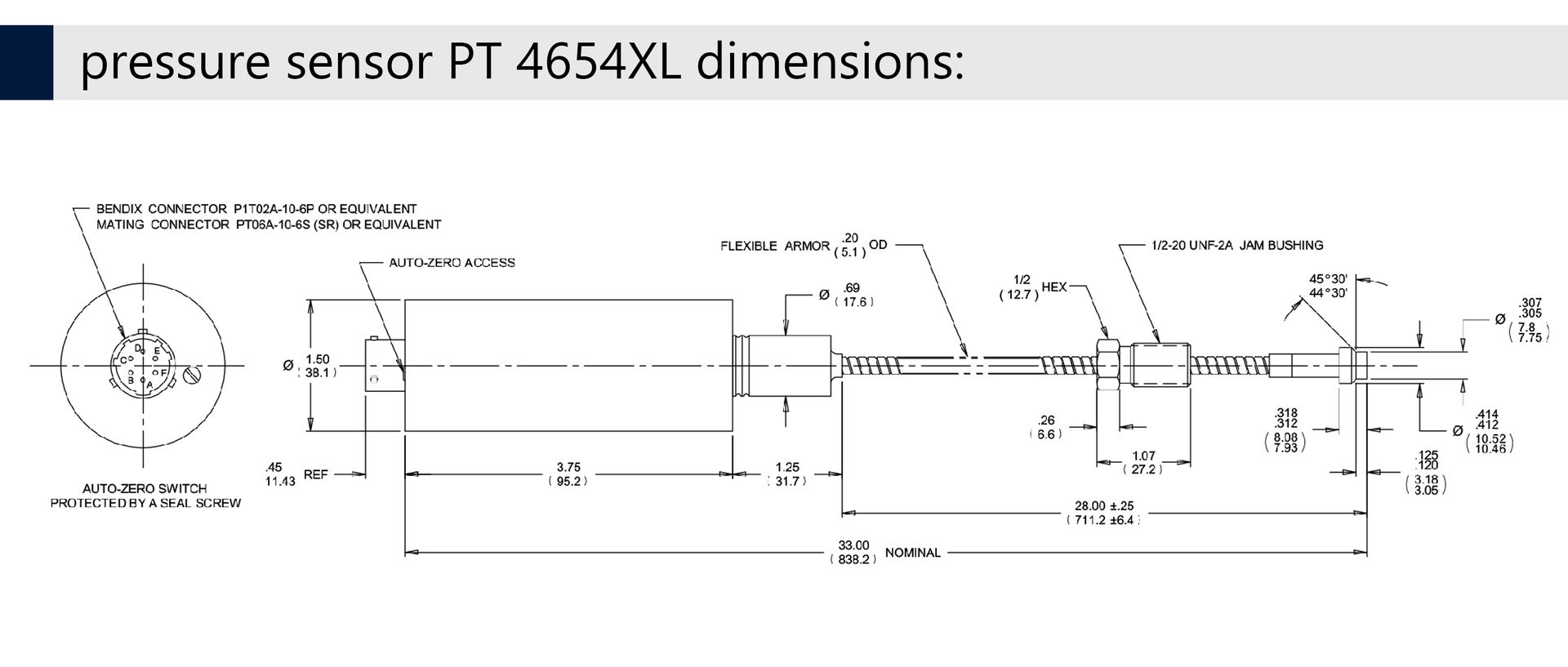

PT 4654XL

The PT4654 models are ideal for measuring melt pressure in a nozzle or manifold for injection applications. The flexible capillary extends from its electronics housing to the installed tip in the machine melt, which guarantees unrivaled strength and extended sensor life.

Each model has a built-in signal amplifier, which has a 4-20 mA output signal for data acquisition or SPC / SQC control programs. The amplified signal offers better immunity to interference than standard mV / V signals. The sensors are supplied as standard with a 1 / 2-20 “UNF-2A process connection and a durable Inconel 718 membrane. Thanks to the cap nut, installation is very easy even in areas with limited access.

PERFORMANCE CHARACTERISTICS

|

Output signal:

|

4-20 mA

|

|

|

Sensor power supply:

|

14 - 36 Vdc

|

|

|

Accuracy*:

|

± 1.0% FSO (Including linearity, repeatability and hysteresis)

|

|

| Repeatability: | ± 0.2% FSO | |

|

Overload pressure: |

2x FSO | |

| Pressure ranges (psi): | 0-3,000, 0-5,000, 0-7,500, 0-10,000, 0-15,000, 0-20,000 | |

| Pressure units: | PSI | |

| Zero setting (±% FS): | ±5% FSO | |

| Bridge resistance: | Vstup: min. 345 ohmů; Výstup: 350 ohmů ± 10% | |

| Insulation resistance: | 1000 megohms @ 50 Vdc | |

| Internal calibration of R-Cal: | 80% FSO ±0.5% |

TEMPERATURE AND MECHANICAL CHARACTERISTICS

|

Sensor technology:

|

4-arm tensometric Wheatstone bridge

|

|

|

Maximum membrane temperature:

|

400°C

|

|

|

Zero shift (due to temperature):

|

36 psi/100°C

|

|

| Maximum temperature of the electronics housing: | -29°C to +85°C | |

|

Zero shift |

± 0.10% FS/ºC max | |

|

Range offset |

±0.02% full scale/°F | |

| Mounting torque: | 500 inch/lbs. max | |

| Temperature sensor (optional): | ||

| Material in contact with the medium: | Inconel 718 |

Certification & Approval

|

EU Declaration of Conformity for Flush Mount mA Output |

|

ISO 9001:2015 |

|

EAC - The Eurasian Conformity mark |

|

GOST Approval |

|

RoHS Compliance Fact Sheet |

|

Safety Integrity Level - SIL2 |