MDA 467

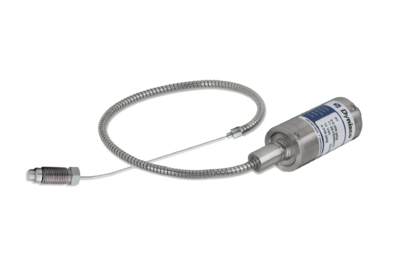

The MDA 467 models are robust and reliable sensors. These models are equipped with a flexible and exposed capillary for easy installation and use in extremely cramped conditions or deviation of the sensor measuring head from the radiant heat of the machine.

The entire MDA range provides an industry standard with a 3.33 mV/V output signal designed to work with most pressure indicators and regulators. This sensor model is equipped with an eight-pin Bendix connector and a 1/2 "-20 UNF 2A or M18x1.5 mounting thread.

PERFORMANCE CHARACTERISTICS

|

Pressure range:

|

from 0 - 35 bar to 0- 2 000 bar

|

|

|

Accuracy:

|

± 0.5% of range (including linearity, repeatability and hysteresis)

|

|

|

Overload capacity:

|

2x pressure range for range 1000 and 1400 bar max. 1750 bar and max. 2400 bar for range 2000 bar

|

|

| Repeatability: | ±0.1% f.s.v | |

| Material in Contact with Media: | 15-5 PH coating of Dynmax® | |

| Sensor connection: | 1/2 "-20 UNF-2A or M18 x 1.5 | |

| Mounting torque: | 25 Nm - 55 Nm | |

| Burst Pressure: | 6x pressure range max. 3000 bar | |

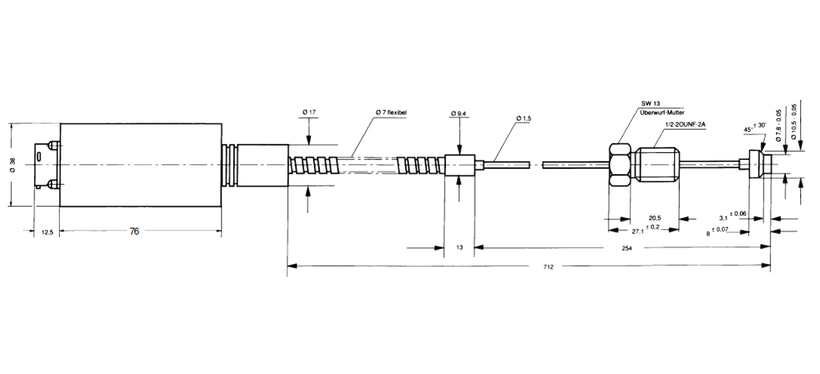

| Konstukce snímače: | MDA 467 - Sensor with flexible and exposed capillary |

TEMPERATURE CHARACTERISTICS

|

Max. membrane temperature:

|

400°C

|

|

|

Zero shift (due to temperature):

|

<0.2 bar / 10°C

|

|

|

-------------------------------------------

|

------------------------------------------------------------------

|

|

| Max. sensor body temperature: | 120°C | |

| Zero shift (due to temperature): | ±0.2% f.s.v./10°C | |

| Shift sensitivity (due to temperature): | ±0.1% f.s.v./10°C (up to 50 bar ±0.2% f.s.v./10°C) |

ELECTRICAL CHARACTERISTICS

|

Supply Voltage:

|

10 Vdc - 12 Vdc

|

|

|

Output signal:

|

3.33 mV/V

|

|

|

Zero setting:

|

±5% f.s.v

|

|

| Connector: : | 8 Bendix PIN connector | |

| Leakage Resistance: | 1000 MΩ at 50Vdc | |

| Strain Resistance: | 350Ω | |

| Internal Shunt Calibration: | 80% f.s.v ±1.0% |

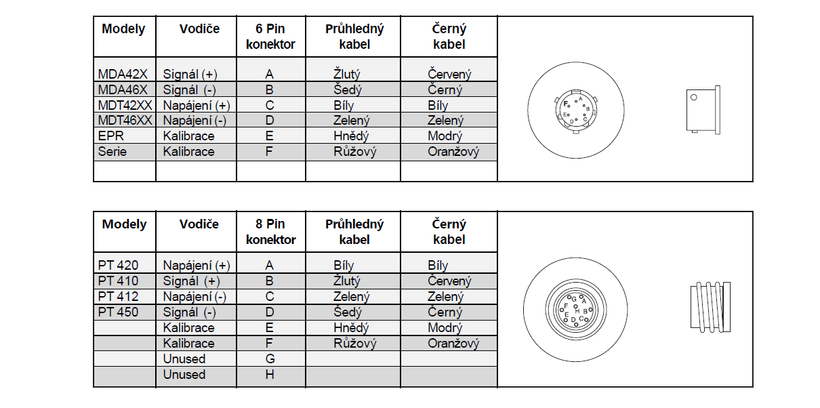

SENSOR DIMENSIONS: CONNECTOR WIRING DIAGRAM:

CONNECTOR WIRING DIAGRAM:

Certification Approval

|

EU Declaration of Conformity for Flush Mount mV/V Output |

|

ISO 9001:2015 |

|

EAC - The Eurasian Conformity mark |

|

GOST Approval |

|

RoHS Compliance Fact Sheet |