Vertex Series

Dynisco’s Vertex melt pressure sensor innovation matches or exceeds the performance of the traditional sensor. The big differences are that Vertex is more robust, much faster, and significantly friendlier to the environment. The direct measurement tip is a simple and elegant design with a more robust diaphragm. Direct measurement of the process reduces errors that are transferred by complicated internal support structures, transmission fill materials, or moving pushrods. The diaphragm thickness is pressure range dependent and can be up to 7.5 times thicker than a traditional sensor. Add to these features, a diaphragm composition of Inconel 718 coated with the corrosion and abrasion resistant properties of Dymax® and experience the true definition of a robust sensor that has proven to increase the life of the sensor and significantly lowers the cost of ownership. Vertex design innovation also extends to the speed of response of the sensor. Faster processes and controls demand faster sensing measurements. Vertex is many times faster than traditional sensors improving real-time production.

Environmental regulations and community conscientiousness are driving sustainability policies and programs in large and small companies. Waste stream reduction and longer life cycles are good for the environment and the budget. There is no mercury, no NaK, no oil, no Gallium, no fill material what-soever. Vertex is also RoHS compliant. Vertex sensors are designed to work with universal pressure indicators. HART digital communication is available for more extensive diagnostics and remote configuration. An optional Type J or K thermocouple is available to provide a melt temperature signal as well as a 4-20 mA temperature output. Vertex is equipped with a 1/2-20 UNF for installation in standard transducer mounting holes. An adapter is also available to install 1/2-20 UNF units into a Button Seal application. A sealed welded shell and electrical connection are available if washdown capability is needed for food or medical applications (not available if thermocouple option TCx is selected).

All sensors in this series can be configured according to your needs. Contact us, we will be happy to help you.

VERTEX -Melt pressure sensor in a design with a fixed stem

VERTEX -Melt pressure sensor in a design with a fixed stem

VERTEX - Melt pressure sensor in a design with a flexible capillary

VERTEX - Melt pressure sensor in combined design with temperature sensor

VERTEX -Melt pressure sensor in a design with a fixed stem

VERTEX - Melt pressure sensors series

Inquiry system

Configure your own product, according to your requirements and needs. If you are not sure about the configuration, tell us in the notes the necessary information about the existing sensor or product, even a competitor. We will be happy to help you find an alternative Dynisco product. If your request is urgent, let us know, we will do our best to help you resolve this situation to your satisfaction as quickly as possible. If we have all the information, we are able to offer a model with minor differences, which is in stock and you can have the necessary product the next day.

Vertex series - Pressure sensor - model:

A New Standard in Durability, Environmental Safety, and Reliability

The pressure range for Vertex is now available from 250 - 10,000 PSI. Vertex is more accurate within our Polymer Test equipment than any other mercury-filled sensor and is ideal for industrial applications that require low pressure. Not only is this an overall improvement to one’s process, but it helps with customers that are focused on sustainability and zero-waste.

Vertex Series - With rigid stem

Rigid Stem pressure sensors are easily installed into the mounting hole of the production line, ensuring a simple and robust design that is suitable for applications where the sensor is not exposed to radiant heat from the line and the electronics are not subjected to extreme temperatures. We do not recommend installing these sensors in a vertical position above the line (12 o'clock position), as radiant heat can negatively affect the sensor's electronics lifespan. In such cases, we recommend using a sensor design with a flexible capillary, which allows the electronics to be diverted away from the radiant heat, ensuring a long sensor life. The main advantages of this type of sensor include resistance to impacts and vibrations, enabling them to withstand mechanical stress, which increases their lifespan and reduces the need for maintenance. They also feature high accuracy, ensured by quality materials and advanced measurement technology, which is crucial for efficient process control.

Rigid Stem pressure sensors are easily installed into the mounting hole of the production line, ensuring a simple and robust design that is suitable for applications where the sensor is not exposed to radiant heat from the line and the electronics are not subjected to extreme temperatures. We do not recommend installing these sensors in a vertical position above the line (12 o'clock position), as radiant heat can negatively affect the sensor's electronics lifespan. In such cases, we recommend using a sensor design with a flexible capillary, which allows the electronics to be diverted away from the radiant heat, ensuring a long sensor life. The main advantages of this type of sensor include resistance to impacts and vibrations, enabling them to withstand mechanical stress, which increases their lifespan and reduces the need for maintenance. They also feature high accuracy, ensured by quality materials and advanced measurement technology, which is crucial for efficient process control.

Vertex Series - With rigid stem and flexible capillary

Pressure sensors with flexible capillaries represent a professional solution suitable for applications with limited space or exposure to radiant heat from heating elements in production lines. Thanks to the thoughtful extended design, the sensor's electronics are located out of reach of the radiant heat source, reducing the risk of damage.

The flexible capillary is designed to be resistant to damage and allow a high degree of bending, which facilitates installation and handling of the sensor. It is essential to properly secure the sensor head to the included adapter, which is part of the package. To achieve optimal performance, we recommend placing the adapter on a part of the machine where unwanted vibrations or shocks do not occur, as these could negatively affect the sensor.

The length of the rod and flexible capillary can be customized according to individual needs, as well as other optional components. This ensures maximum flexibility in integrating the sensor into a wide range of industrial applications.

Vertex Series - Combined sensor with rigid stem, flexible capillary and built-in temperature sensor

Combined pressure sensors with flexible capillaries represent a professional solution suitable for applications with limited space or exposure to radiant heat from heating elements in production lines. Thanks to the thoughtful extended design, the sensor's electronics are located out of reach of the radiant heat source, reducing the risk of damage.

Additionally, these sensors are equipped with a temperature sensor, allowing the customer to choose the type of sensor, whether it is a type J, K thermocouple, or an RTD (pt100). By selecting a compatible sensor for temperature measurement, the customer obtains information about the melt temperature from a single process connection, increasing measurement efficiency and accuracy.

The flexible capillary is designed to be resistant to damage and allow a high degree of bending, which facilitates installation and handling of the sensor. It is essential to properly secure the sensor head to the included adapter, which is part of the package. To achieve optimal performance, we recommend placing the adapter on a part of the machine where unwanted vibrations or shocks do not occur, as these could negatively affect the sensor.

The length of the rod and flexible capillary can be customized according to individual needs, as well as other optional components. This ensures maximum flexibility in integrating the sensor into a wide range of industrial applications.

Performance Characteristics

| Input, Excitation: |

mV/V: 10-12VDC; mA; voltage 16-36VDC |

| Diaphragm Operating Temp. Range1: |

-40°F to +752°F (-40°C to +400°C |

| Electronics Operating Temp. (Max): |

185°F (85°C) |

| Zero Shift (Electronics Temp.): |

0.012%/°F (0.022%/°C) |

| Span Shift (Electronics Temp.): |

0.012%/°F (0.022%/°C) |

| Hex/Transition Temp. (Max): |

300°F (150°C) |

| Zero Shift (Hex Temp.): |

0.022%/°F (0.039%/°C) |

| Overload Pressure Rating: |

1.5x FPS |

| Pressure Ranges (PSI): |

2.5C, 5C, 7.5C, 1.0M, 1.5M, 3M, 5M, 7.5M or 10M |

| Pressure Units: |

PSI, Bar, Kg/cm2 , MPa, KPA |

| Zero Balance Adjustment (±% FSO): |

mV/V: na; mA: ±3%, Voltage ±20% |

| Zero Balance Setting (±% FSO): |

mV/V: 10%; mA: ±3%, Voltage ±3% |

| Insulation Resistance: |

mV/V: 100 MΩ @50VDC |

| Internal Shunt Calibration (R-Cal): |

80% FSO ±1% FSO |

| Zero Shift (Process Temp. Change): |

1.0%/100°F (2.0%/100°C) |

Mechanical & Packaging

| Diaphragm Wetted Parts: |

Inconel 718, DyMax® coated |

| Mounting Torque: |

250 in-lbs recommended, 500 inlbs max |

| Temp. Sensor (Optional): |

Type J or Type K thermocouple (available on flex units only) |

| Ingress Protection: |

IP54 (IP67 if welded and temperature sensor code is NTR) |

Approvals & Certifications

| CE: |

Directive 2004/108/EC |

| ISO: |

ISO9001:2008 production environment |

| RoHS 1: |

Directive 2011/95/EC |

| RoHS 2: |

Directive 2011/65/EU |

| ATEX IS: |

Intrinsically Safe |

1 Diaphragm Operating Temp. Range refers to the functional limits of the snout tip. Refer to the manual for greater detail on the operating compensated temperature ranges of the diaphragm tip, flex and electronics.

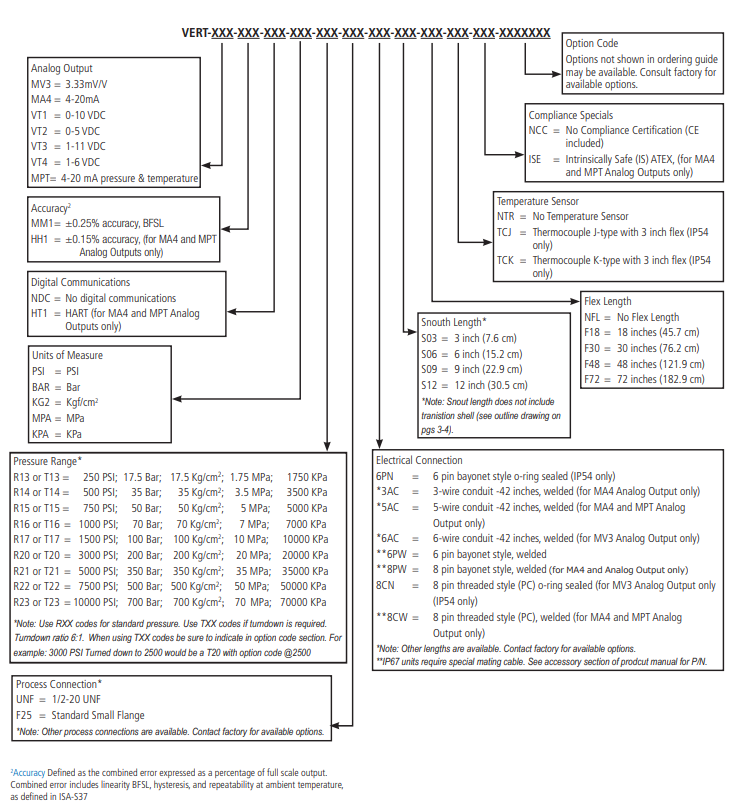

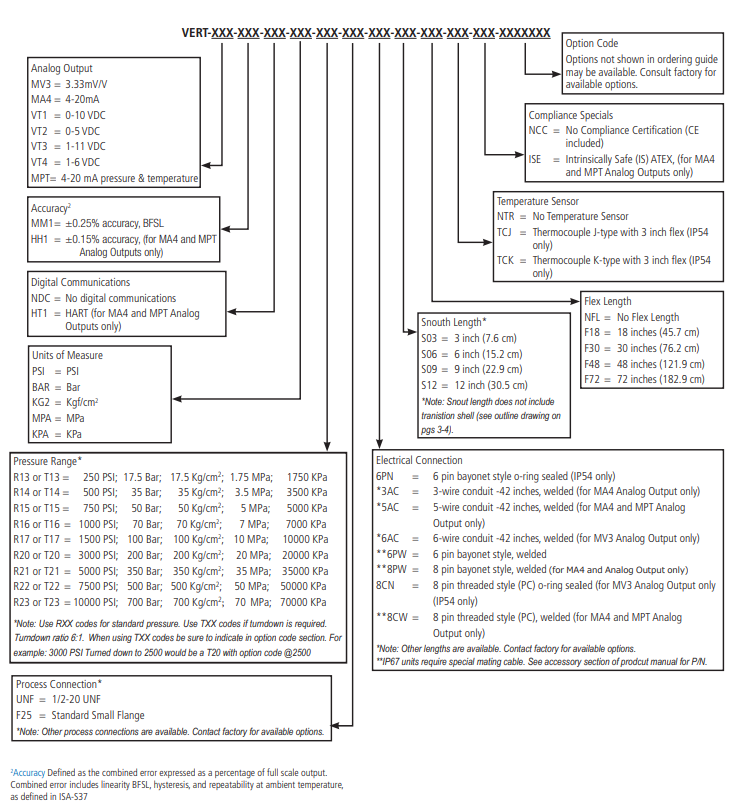

Ordering Guide for Vertex Series

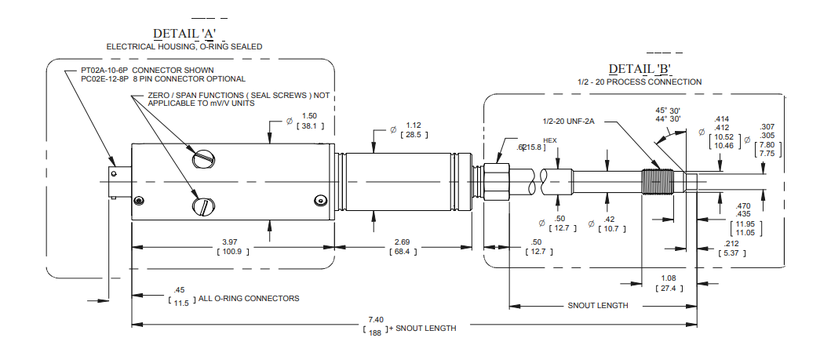

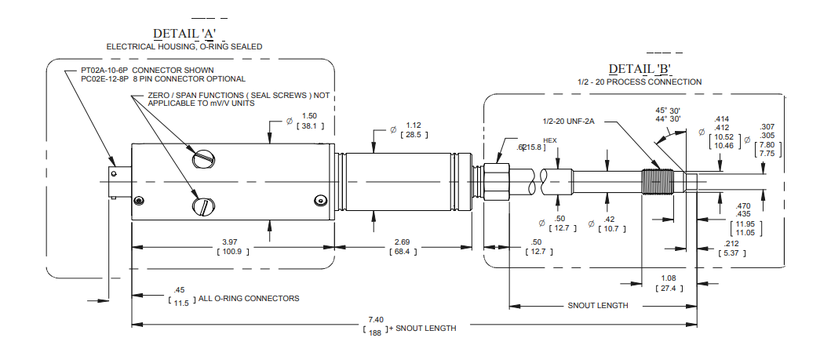

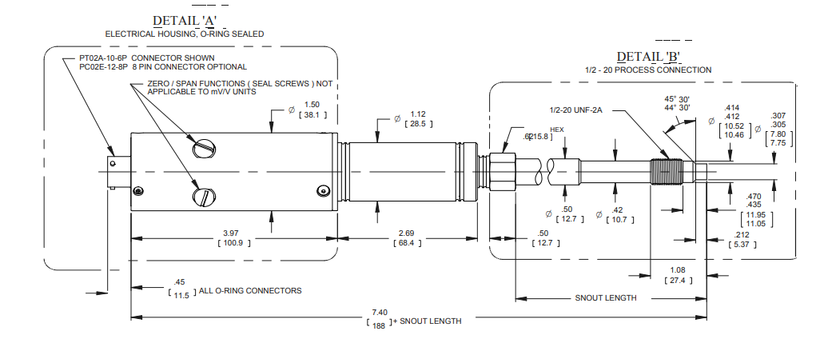

Vertex Series - With rigid stem - Dimensions

All dimensions are inches (mm) unless otherwise specified.

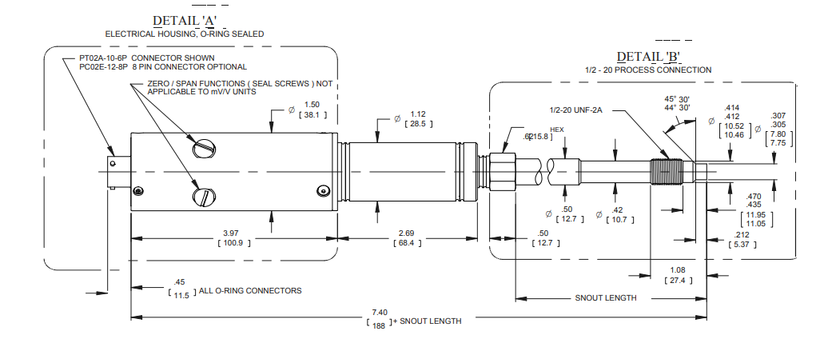

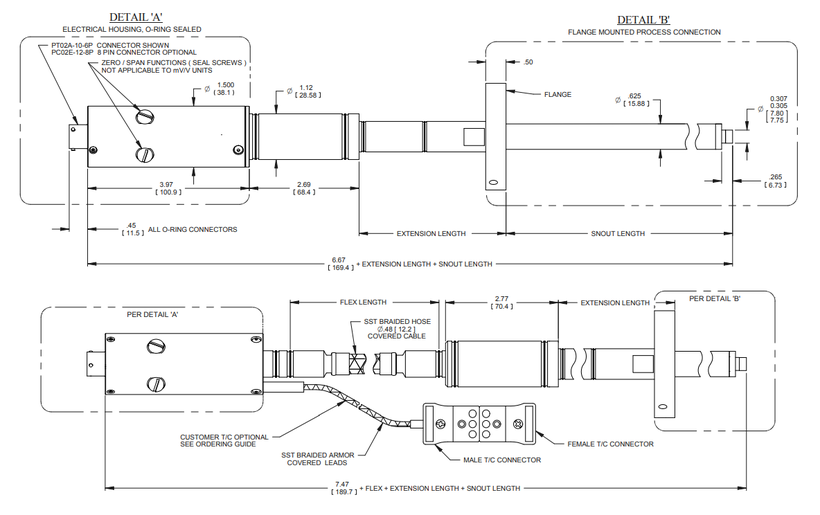

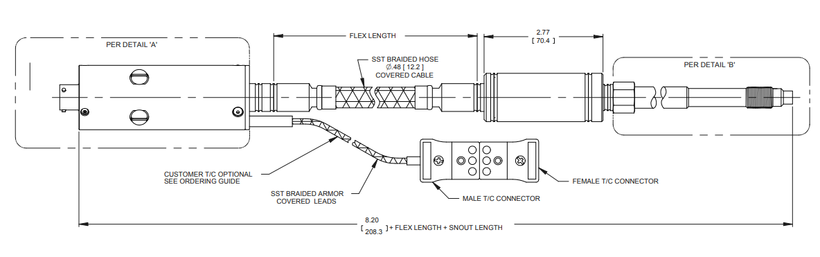

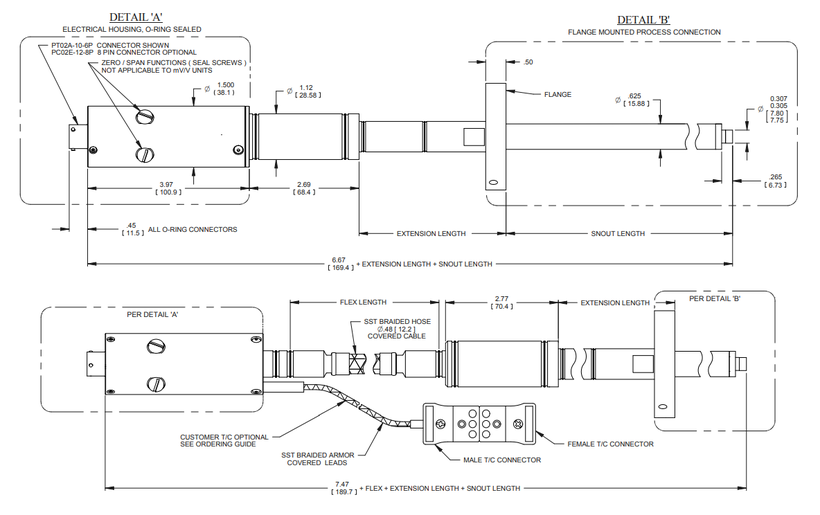

Vertex Series - With flexible capillary - Dimensions

All dimensions are inches (mm) unless otherwise specified.

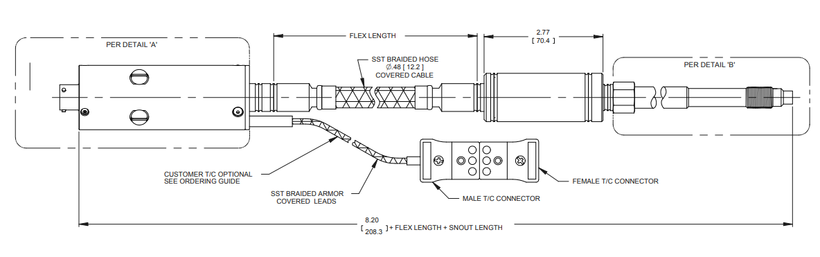

Vertex Series - Combined sensor - Dimensions

All dimensions are inches (mm) unless otherwise specified.

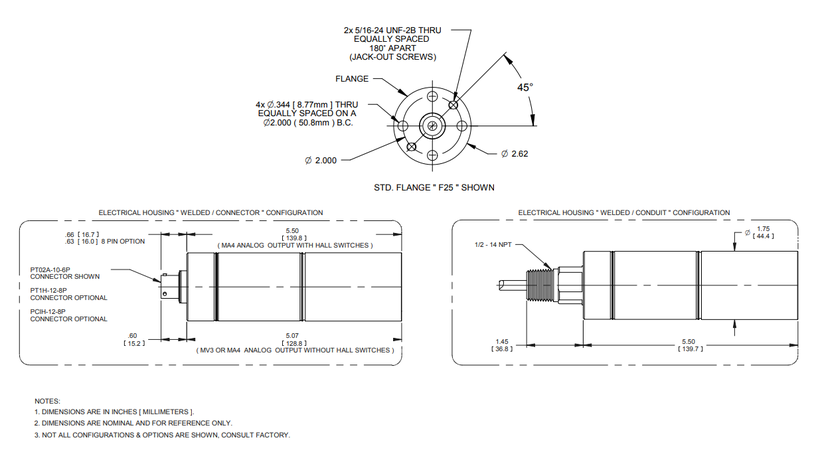

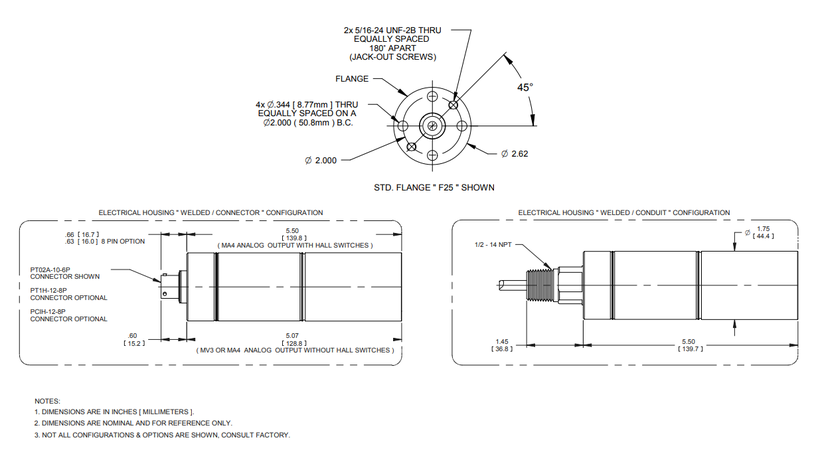

Vertex Series - Flange connection - Dimensions

All dimensions are inches (mm) unless otherwise specified.

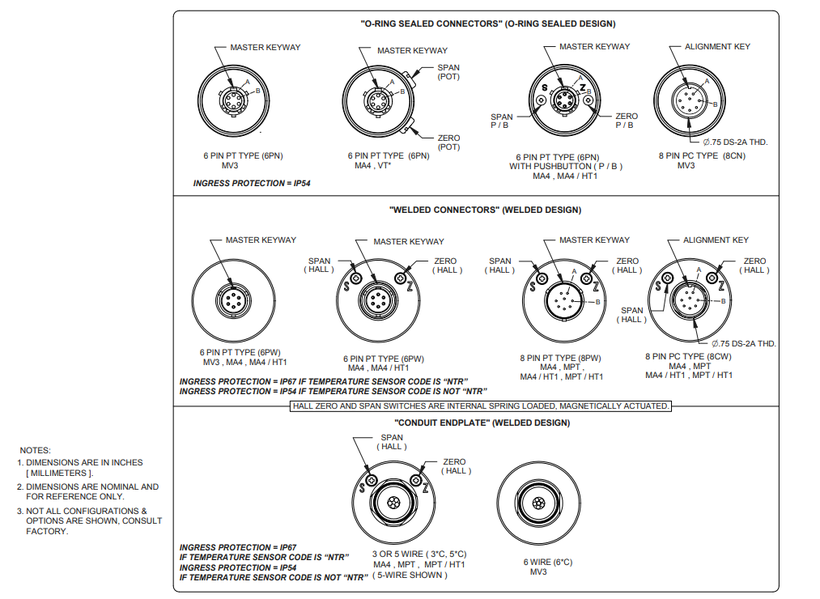

Vertex Series - Detail - Dimensions

All dimensions are inches (mm) unless otherwise specified.

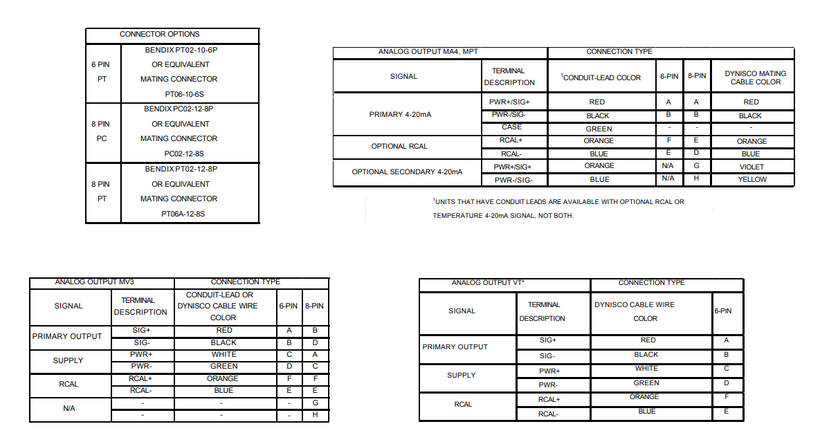

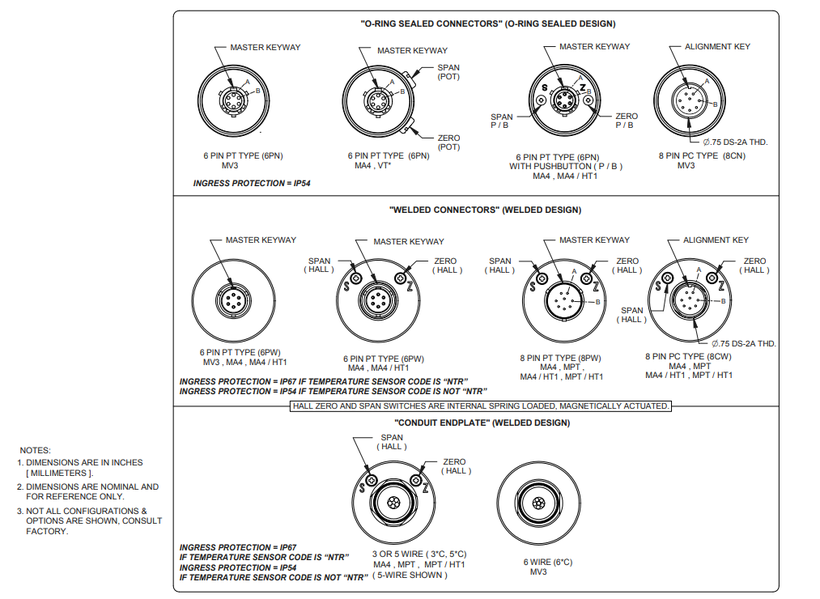

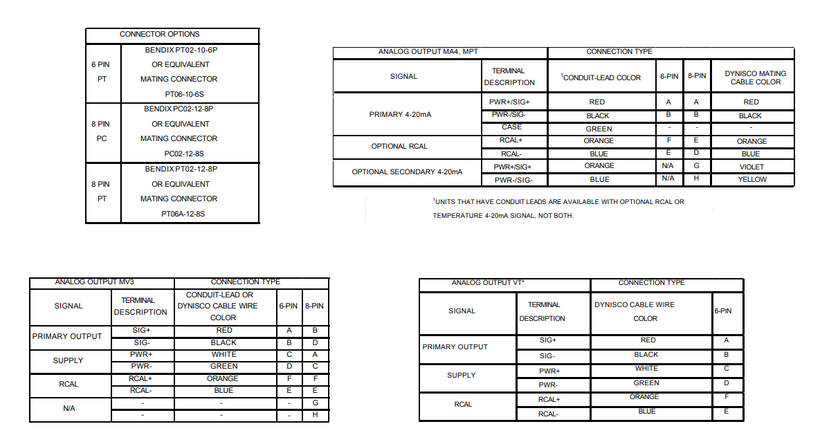

Vertex Series - Electrical Connection

All dimensions are inches (mm) unless otherwise specified.

Torque wrench Wera 075611 Click-Torque B 2 with switch ratchet 3/8 "(20 - 100 Nm)

Wera Click-Torque torque wrenches are supplied as switch ratchets (with connection dimensions 1/4 ", 3/8", 1/2 "and 3/4") or with clamping for socket tools (9x12 mm, 14x18 mm) for tightening torques from 2.5 Nm up to 1,000 Nm.

All Wera Click-Torque torque wrenches manufactured in accordance with DIN EN ISO 6789 are supplied with a declaration of conformity.

Installation of transducers into improperly cleaned or sized holes is one of the major causes of damage to these instruments. With this kit, the .312" tip diameter hole, the 45 degree seating surface, and the .451" hole can be cleaned. The kit includes a gauging plug which is used to verify that the hole has been correctly machined and cleaned. M10 and M18 cleaning kits also available.

The Dynisco Transducer Mounting Hole Machining Tool Kit contains all of the necessary drills and taps to prepare a standard 1/2 - 20 UNF transducer mounting hole and the 45 degree seat. All tools included in this kit are made of premium grade, high strength tool steel. Care should be taken in the use of proper speeds and feeds, lubricants, and a method to assure continual alignment of each progressing tool. M10 and M18 kits are also available.

The 1480 is a Universal Pressure or Temperature Input Indicator with single or dual configurable alarms, as well as optional linear retransmission of displayed Process Variable. Ideal for use in Extrusion applications.

The 1490 is a Universal Input Indicator with single or dual configurable alarms, optional linear retransmission of Process Variable, Transmitter power supply option as well as optional Modbus communications.

The UPR900 is a compact 1/4 DIN process indicator. The UPR900 can display your choice of engineering units related to a selectable range of input types. Add an optional secondary input for an all-in-one display of polymer melt pressure and temperature. The secondary input can be strain gauge to indicate differential pressure measurement. The UPR900 includes two standard assignable alarms with the option to add a 3rd.

The ATC990 with a graphical/text LCD display is a universal input process controller with advanced functionality including Trend views as well as Digital Inputs, USB and data logging options. It provides a cost-effective way to control a single process parameter, such as for a plastics extruder. Designed to improve user efficiency many features are integrated to reduce commissioning time, simplify operation and minimize maintenance downtime. Reliably auto-tune and alarm on strain gauge, DC voltage, temperature or current inputs.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.