PT467E

The PT647E series of pressure sensors is an ideal choice for measuring the melt pressure of polymers in places where there is not enough space for a conventional sensor. The exposed part of the capillary allows a bend with a small radius of 3 mm and thanks to the special construction of the tip with a freely rotating nut simplifies installation and allows the use of Dynisco sensors even where it is not possible to install a standard sensor with a fixed rod or flexible capillary.

Standard transducers are supplied with a DyMax® coated membrane to increase wear resistance and long life. The 6-pin Bendix connector is used for easy connection and disconnection.

All sensors in this series can be configured according to your needs. Contact us, we will be happy to help you.

PT 467 - Melt pressure sensor in design with exposed capillary

PT 467 - Melt pressure sensor in design with exposed capillary

Adjusting screws - used to adjust the zero and upper range of the sensor

Sensor terminal and compatible cable connector

Inquiry system

Configure your own product according to your requirements and needs. If you are unsure of the configuration, provide us in the notes the necessary information about the existing sensor or product, even a competitor. We will be happy to help you find an alternative Dynisco product. If your request is urgent, let us know. We will do our best to help you resolve this situation to your satisfaction as quickly as possible. If we have all the information, we are able to offer a model with minor differences, which is in stock and you can have another product available the next day.

If you need more information do not hesitate to contact us.

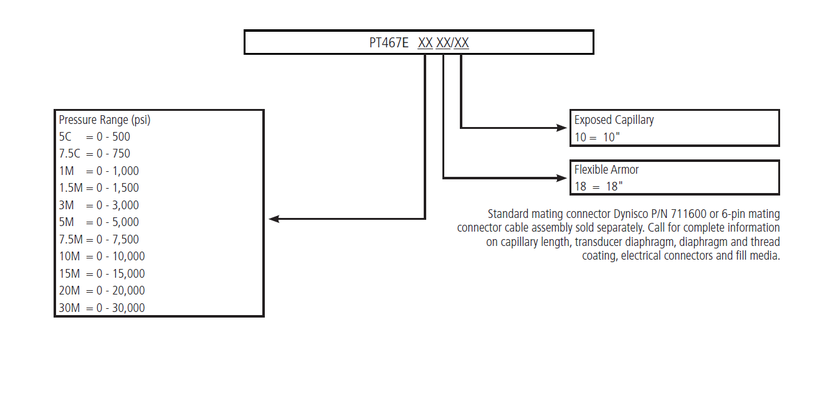

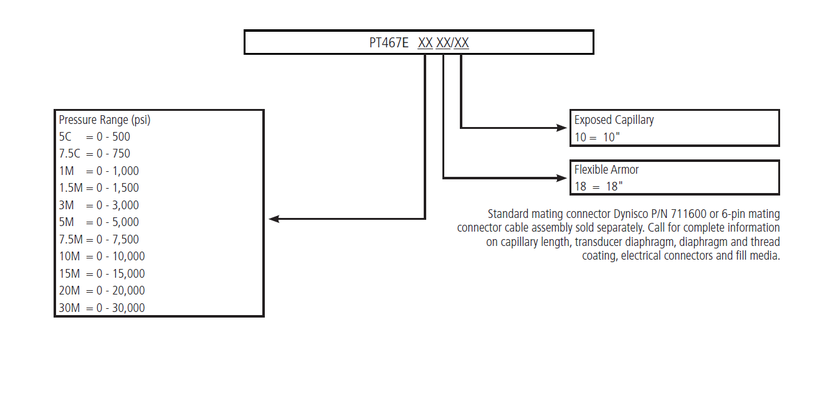

Dynisco configuration code:

High accuracy melt pressure transducer for space restricted areas

Our pressure sensors offer efficient, accurate, and durable solutions for reliable and safe pressure measurement. These sensors are used in a variety of industrial areas, where they monitor and measure the pressure of molten materials, ensuring optimal operation of production processes. Due to their resistance to high temperatures and pressures, which are typical for these applications, they represent a suitable choice for diverse uses. When selecting a sensor, it is important to consider the specific requirements of your application, such as temperature range, pressure range, and materials with which the sensor will interact. The correct choice of sensor guarantees reliable and accurate results and a long service life of the device without any problems. Installing the sensor into the mounting hole of the production line is simple.

PT467E Pressure Sensors - With flexible and exposed capillary

Innovative pressure sensor, perfectly designed for injection applications with minimal installation space. Thanks to its unique features and state-of-the-art technical parameters, this sensor can cope with demanding conditions in any environment. The manufacturer spared no expense in advanced technologies and sophisticated production processes, enabling the sensor to achieve very small dimensions and low weight without any compromise to its outstanding performance. The pressure sensor is an ideal solution for a wide range of injection applications, thanks to its exceptional resistance to vibrations, which it can withstand very well. A pleasant bonus is the easy and hassle-free installation of this sensor in spaces with limited dimensions.

Innovative pressure sensor, perfectly designed for injection applications with minimal installation space. Thanks to its unique features and state-of-the-art technical parameters, this sensor can cope with demanding conditions in any environment. The manufacturer spared no expense in advanced technologies and sophisticated production processes, enabling the sensor to achieve very small dimensions and low weight without any compromise to its outstanding performance. The pressure sensor is an ideal solution for a wide range of injection applications, thanks to its exceptional resistance to vibrations, which it can withstand very well. A pleasant bonus is the easy and hassle-free installation of this sensor in spaces with limited dimensions.

Performance Characteristics

| Pressure Range: |

0- 30 000 PSI |

| Maximum pressure: |

2 x full range or 35,000psi (whichever is less |

| Accuracy: |

±0.5% FSO |

| Repeatability: |

± 0.2% FSO |

| Resolution: |

Infnite |

Maximum Overload

(without influencing operating data): |

2 x full range or 35,000psi (whichever is less |

| Material in Contact with Media: |

Dymax® coated 15-5 PH SST |

| Mounting torque: |

500 inch - lbs. maximum |

| Weight: |

1.5 lbs |

Temperature Characteristics

| Diaphragm |

|

| Max. Temperature: |

750°F (400°C) |

| Zero Shift Due to Temperature Change: |

25 psi/100°F maximum (45 psi/100°C) |

| Housing |

|

| Max. Temperature: |

250°F (121°C) |

| Zero Shift Due to Temperature Change: |

±0.05% full scale/°F maximum (±0.10% full scale/°C) |

| Sensitivity Shift Due to Temperature Change: |

±0.02% full scale/°F maximum (±0.04% full scale/°C) |

Electrical Characteristics

| Configuration: |

4-arm Wheatstone bridge strain gage |

| Bridge resistance: |

Input: 345 Ohms minimum; Output: 350 Ohms ±10% |

| Zero balance: |

±5% FSO |

| Full scale output: |

3.33 mv/V ±2% |

| Excitation: |

10 Vdc recommended, 12Vdc maximum |

| Internal shunt calibration (R-Cal): |

80% FSO ±0.5% |

| Insulation resistance: |

1000 megohms at 50 Vdc |

Ordering Guide for PT467E

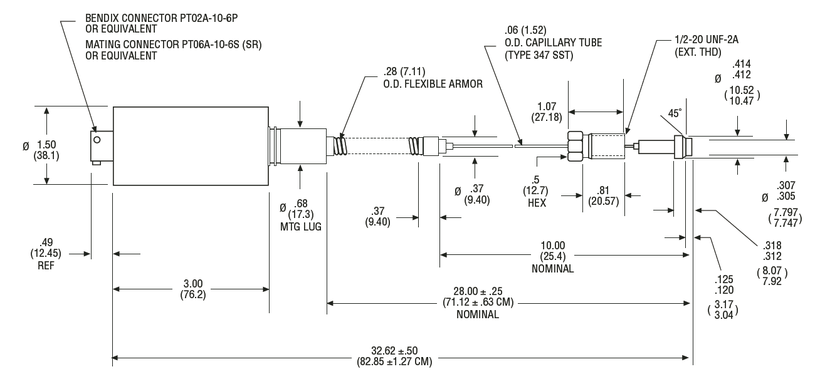

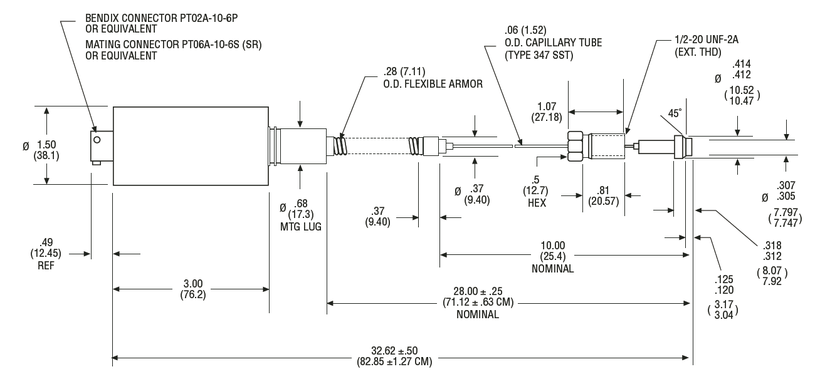

PT467E - Dimensions

All dimensions are inches (mm) unless otherwise specified.

Torque wrench Wera 075611 Click-Torque B 2 with switch ratchet 3/8 "(20 - 100 Nm)

Wera Click-Torque torque wrenches are supplied as switch ratchets (with connection dimensions 1/4 ", 3/8", 1/2 "and 3/4") or with clamping for socket tools (9x12 mm, 14x18 mm) for tightening torques from 2.5 Nm up to 1,000 Nm.

All Wera Click-Torque torque wrenches manufactured in accordance with DIN EN ISO 6789 are supplied with a declaration of conformity.

Installation of transducers into improperly cleaned or sized holes is one of the major causes of damage to these instruments. With this kit, the .312" tip diameter hole, the 45 degree seating surface, and the .451" hole can be cleaned. The kit includes a gauging plug which is used to verify that the hole has been correctly machined and cleaned. M10 and M18 cleaning kits also available.

The Dynisco Transducer Mounting Hole Machining Tool Kit contains all of the necessary drills and taps to prepare a standard 1/2 - 20 UNF transducer mounting hole and the 45 degree seat. All tools included in this kit are made of premium grade, high strength tool steel. Care should be taken in the use of proper speeds and feeds, lubricants, and a method to assure continual alignment of each progressing tool. M10 and M18 kits are also available.

The 1480 is a Universal Pressure or Temperature Input Indicator with single or dual configurable alarms, as well as optional linear retransmission of displayed Process Variable. Ideal for use in Extrusion applications.

The 1490 is a Universal Input Indicator with single or dual configurable alarms, optional linear retransmission of Process Variable, Transmitter power supply option as well as optional Modbus communications.

The UPR900 is a compact 1/4 DIN process indicator. The UPR900 can display your choice of engineering units related to a selectable range of input types. Add an optional secondary input for an all-in-one display of polymer melt pressure and temperature. The secondary input can be strain gauge to indicate differential pressure measurement. The UPR900 includes two standard assignable alarms with the option to add a 3rd.

The ATC990 with a graphical/text LCD display is a universal input process controller with advanced functionality including Trend views as well as Digital Inputs, USB and data logging options. It provides a cost-effective way to control a single process parameter, such as for a plastics extruder. Designed to improve user efficiency many features are integrated to reduce commissioning time, simplify operation and minimize maintenance downtime. Reliably auto-tune and alarm on strain gauge, DC voltage, temperature or current inputs.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.