SPX4352 & SPX4672

The Dynisco SPX 4-Series is a smart 4-20mA pressure transmitter designed for use in hazardous locations and are available with a variety of different process and electrical connections These amplified transmitters eliminate the need for external signal conditioning. All models can interface directly with distributed control systems, PLC's, computers, and similar high level control devices. Optional thermocouple or RTD configurations are available to provide melt temperature.

All sensors in this series can be configured according to your needs. Contact us, we will be happy to help you.

Dynisco SPX 2 Series Smart Pressure Sensor

Dynisco SPX 2 Series Smart Pressure Sensor

Dynisco SPX 2 Series Smart Pressure Sensor

Dynisco SPX 2 Series Smart Pressure Sensor

Dynisco SPX 2 Series Smart Pressure Sensor

Dynisco SPX 2 Series Smart Pressure Sensor

Dynisco SPX 2 Series Smart Pressure Sensor

Dynisco SPX 2 Series Smart Pressure Sensor

Dynisco SPX 2 Series Smart Pressure Sensor

Dynisco SPX 2 Series Smart Pressure Sensor

Dynisco SPX 2 Series Smart Pressure Sensor

Inquiry system

Configure your product, according to your requirements and needs. If you are not sure about the configuration, make the necessary information in the notes about the manufacturer of the sensor, even a competing one. We will be happy to help you find an alternative from Dynisco products. If your request is urgent, let us know, we will do our best to help you resolve this situation as quickly as possible. If we have this information, we can offer a model with small differences and you can have a sensor in your company the next day.

SPX-4 series - Pressure sensor - model:

General Purpose Smart Pressure Sensors for Hazardous Locations

SPX 4-Series

All models can interface directly with distributed control systems, PLC's, computers, and similar high level control devices. Optional thermocouple or RTD configurations are available to provide melt temperature.

The SPX4 Series includes models SPX4222, SPX4622, SPX4352, SPX4672, SPX4232, and SPX4502.

⚠ WARNING: This product can expose you to chemicals including mercury and lead, which is known to the State of California to cause cancer and reproductive harm. For more information, go to www.P65Warnings.ca.gov.

SPX4352 & SPX4672 Series

The Dynisco SPX 4-Series is a smart 4-20mA pressure transmitter designed for use in hazardous locations and are available with a variety of different process and electrical connections These amplified transmitters eliminate the need for external signal conditioning. All models can interface directly with distributed control systems, PLC's, computers, and similar high level control devices. Optional thermocouple or RTD configurations are available to provide melt temperature.

Performance Characteristics

| Output: |

4 - 20 mA, with optional HART™ |

| Input Voltage: |

16 - 36 Vdc (Std); 16 - 30 Vdc (ATEX IS) |

Accuracy:

Accuracy is defined as the combined error expressed as a percentage of full scale output with the specifications of: Electronics ambient temperature, capillary of <= 36"; DyMax coated 15-5 SST diaphragm; Best Straight Line (BSL) %FS, per ISA-37.1 Consult Factory for availability and specifications of other configurations |

4222 ± 0.25% for pressure ranges >1,500 psi; ± 0.50% for pressure ranges < 1,500 psi 4232 ± 0.25% for pressure ranges >1,500 psi; ± 0.50% for pressure ranges < 1,500 psi 4352 ± 0.25% for pressure ranges > 1,500 psi; ± 0.50% for pressure ranges < 1,500 psi 4502 ± 0.50%

4622 ± 0.50%

4672 ± 0.50%

|

| Repeatability: |

±0.1% |

| Rangeability: |

6:1 Turndown |

| Over Pressure: |

2X FSO or 35,000 psi,whichever is less 1.2 X FSO 35,000 - 72,500 psi |

| Zero Balance Adjustment Range: |

-40% to +10%; -80% to 20% for FSP < 500 psi |

| Load Resistance |

500 Ω @ 24 Vdc, 1,000 Ω @ 36 Vdc |

| Electronics Ambient Temperature: |

70°F (20°C) |

| Electronics Operating Temperature: |

-20 to 185°F (-29 to 85°C) |

| Diaphragm Temperature: |

750°F (400°C) max [SPX4502 model limited to 600°F (315°C)] |

| Electronics Compenstated Temperature Range: |

0 to 150°F (-18 to 65°C) |

| Zero Shift (Electronics Temp Change): |

4222: 0.01% F.S./°F max (0.02% F.S./°C max)

4232: 0.01% F.S./°F max (0.02% F.S./°C max)

4352: 0.01% F.S./°F max (0.02% F.S./°C max)

4502: 0.01% F.S./°F max (0.02% F.S./°C max)

4622: 0.05% F.S./°F max (0.10% F.S./°C max)

4672: 0.05% F.S./°F max (0.10% F.S./°C max |

| Span Shift (Electronics Temp Change): |

4222: 0.01% F.S./°F max (0.02% F.S./°C max)

4232: 0.01% F.S./°F max (0.02% F.S./°C max)

4352: 0.01% F.S./°F max (0.02% F.S./°C max)

4502: 0.01% F.S./°F max (0.02% F.S./°C max)

4622: 0.02% F.S./°F max (0.04% F.S./°C max)

4672: 0.02% F.S./°F max (0.04% F.S./°C max) |

| Zero Shift (Snout Temp Change): |

4222: 15 psi/100°F (27 psi/100°C) typical

4232: 15 psi/100°F (27 psi/100°C) typical

4352: 15 psi/100°F (27 psi/100°C) typical

4502: 1 psi/100°F (from 75-450°F); 2 psi/100°F (from 450-600°F) typical

4622: 25 psi/100°F (45 psi/100°C) typical

4672: 25 psi/100°F (45 psi/100°C) typical |

Mechanical Characteristics

| Mounting Torque: |

4222: 500 inch-lbf max

4232: 50 inch-lbf max

4352: 500 inch-lbf max

4502: 350 inch-lbf max

4622: 500 inch-lbf max

4672: 500 inch-lbf max

|

| Standard Wetted Parts: |

DyMax coated 15-5 PH SST |

Approvals & Certifications

| ATEX/IECEx Intrinsically Safe |

|

| SIL 2 (pressure output) & PL'c' (relay output) |

|

| Additional approvals available (consult factory) |

|

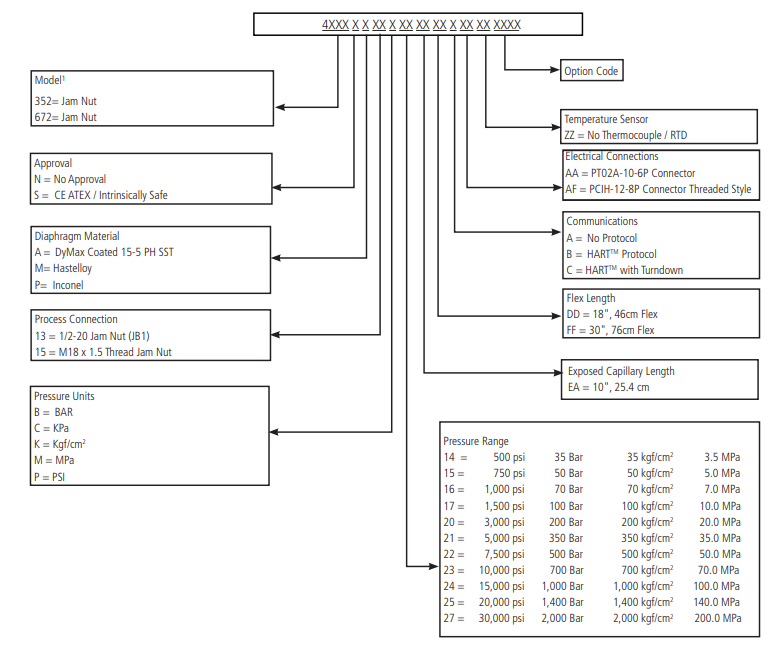

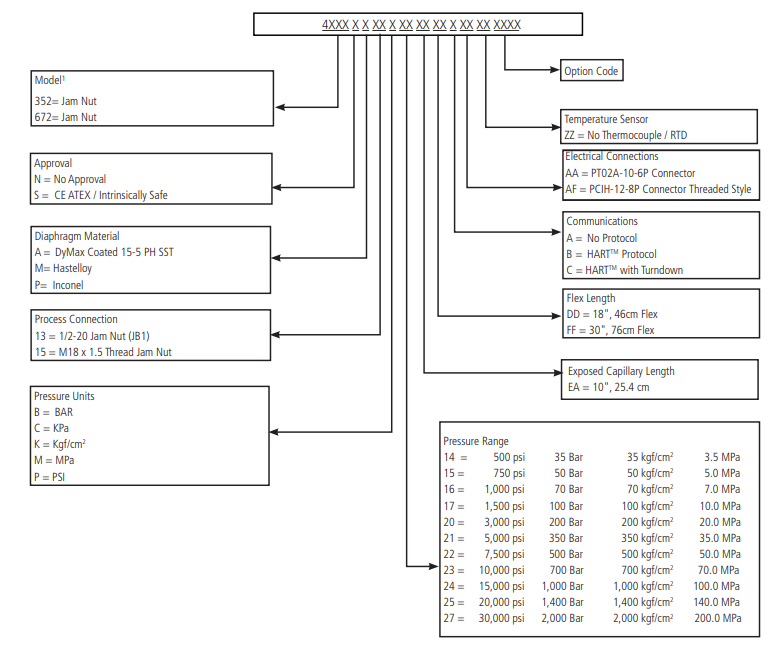

Ordering Guide for Models SPX4352 & SPX4672

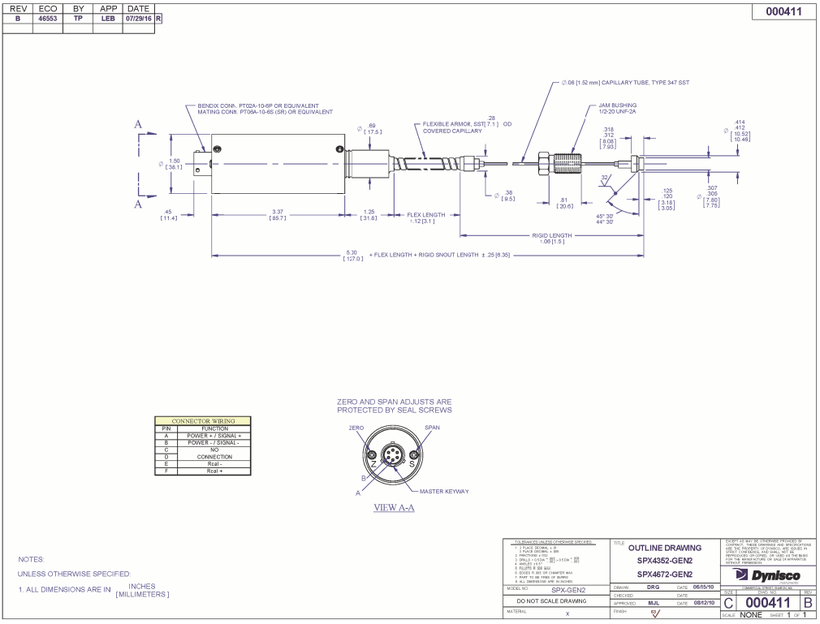

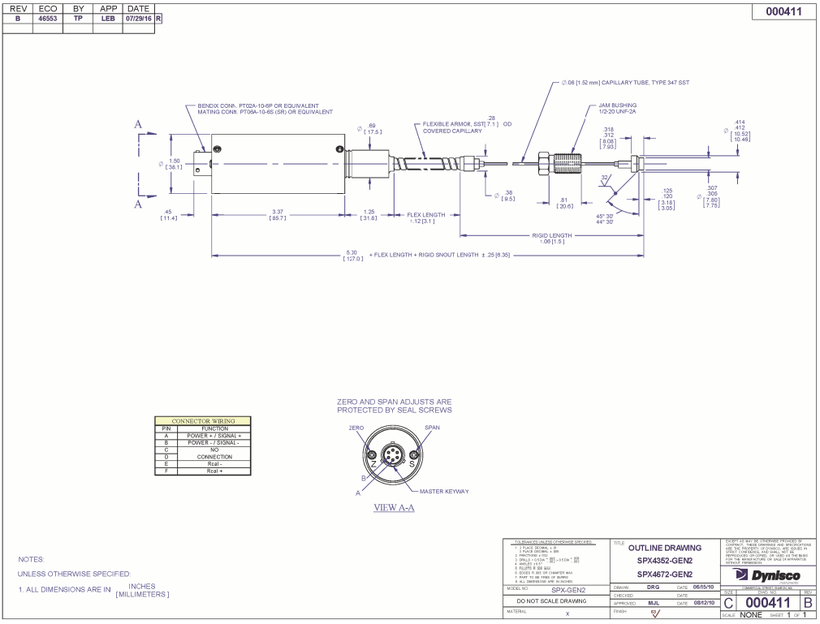

SPX4352 & SPX4672 Series - Dimensions

All dimensions are inches (mm) unless otherwise specified.

Installation of transducers into improperly cleaned or sized holes is one of the major causes of damage to these instruments. With this kit, the .312" tip diameter hole, the 45 degree seating surface, and the .451" hole can be cleaned. The kit includes a gauging plug which is used to verify that the hole has been correctly machined and cleaned. M10 and M18 cleaning kits also available.

The Dynisco Transducer Mounting Hole Machining Tool Kit contains all of the necessary drills and taps to prepare a standard 1/2 - 20 UNF transducer mounting hole and the 45 degree seat. All tools included in this kit are made of premium grade, high strength tool steel. Care should be taken in the use of proper speeds and feeds, lubricants, and a method to assure continual alignment of each progressing tool. M10 and M18 kits are also available.

Torque wrench Wera 075611 Click-Torque B 2 with switch ratchet 3/8 "(20 - 100 Nm)

Wera Click-Torque torque wrenches are supplied as switch ratchets (with connection dimensions 1/4 ", 3/8", 1/2 "and 3/4") or with clamping for socket tools (9x12 mm, 14x18 mm) for tightening torques from 2.5 Nm up to 1,000 Nm.

All Wera Click-Torque torque wrenches manufactured in accordance with DIN EN ISO 6789 are supplied with a declaration of conformity.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.