Temperature Controller 1498 Series

Temperature Controller 1498 Series

Temperature Controller 1498 Series

Temperature Controller 1498 Series

Temperature Controller 1498 Series

Temperature Controller 1498 Series

Inquiry system

Configure your own product according to your requirements and needs. If you are unsure of the configuration, provide us in the notes the necessary information about the existing sensor or product, even a competitor. We will be happy to help you find an alternative Dynisco product. If your request is urgent, let us know. We will do our best to help you resolve this situation to your satisfaction as quickly as possible. If we have all the information, we are able to offer a model with minor differences, which is in stock and you can have another product available the next day.

If you need more information do not hesitate to contact us.

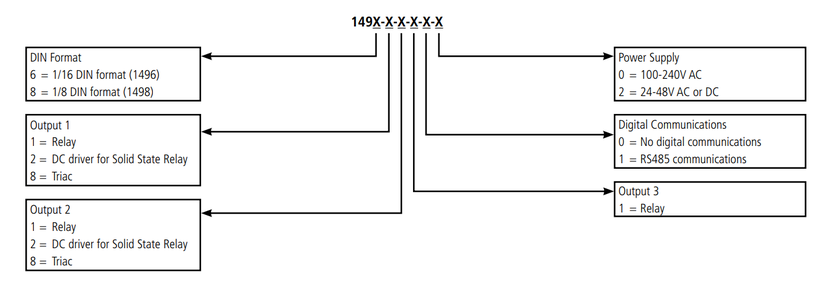

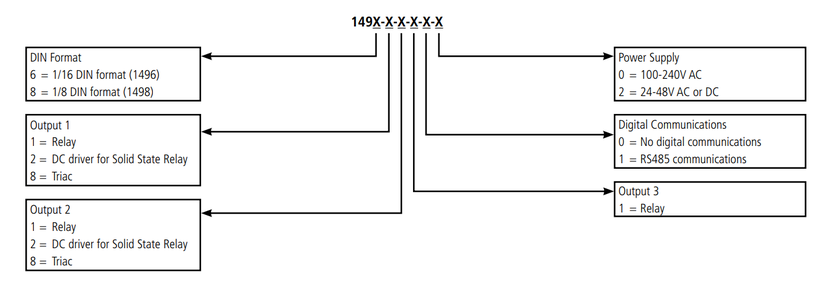

Dynisco Configuration Code:

DIN Mounted Temperature Controllers

Dynisco 1498 Series Temperature Controllers

The Dynisco 1496 & 1498 Series Temperature Controllers are an economic solution to precision temperature control of extruders. With two DIN sizes and multiple output configurations, the controller is suitable for twin and single screw extruders, both heat only die and adapter zones, in addition to heat/cool for barrel zones. The 1496 (1/16 DIN format) & 1498 (1/8 DIN format) Series can also be used in an indicator-only mode, allowing one instrument to be used for all applications. With three default parameter sets for Indicator, heat and heat/cool modes, The 1496 & 1498 Series controllers offer the ultimate in flexibility for the control of industrial plastic extruders. The 1496 & 1498 Series was designed for fast configuration to match specific settings and default parameters of the extruder. Three alarm settings are standard and can be used for process high, process low, SP deviation, band, logical OR / AND, loop alarm for process control security. Process alarms have adjustable hysteresis.

The Dynisco 1496 & 1498 Series Temperature Controllers are an economic solution to precision temperature control of extruders. With two DIN sizes and multiple output configurations, the controller is suitable for twin and single screw extruders, both heat only die and adapter zones, in addition to heat/cool for barrel zones. The 1496 (1/16 DIN format) & 1498 (1/8 DIN format) Series can also be used in an indicator-only mode, allowing one instrument to be used for all applications. With three default parameter sets for Indicator, heat and heat/cool modes, The 1496 & 1498 Series controllers offer the ultimate in flexibility for the control of industrial plastic extruders. The 1496 & 1498 Series was designed for fast configuration to match specific settings and default parameters of the extruder. Three alarm settings are standard and can be used for process high, process low, SP deviation, band, logical OR / AND, loop alarm for process control security. Process alarms have adjustable hysteresis.

Performance Characteristics

| Thermocouple Input Types: |

J, K, C, R, S, T, B, L, N & PtRh20% vs. PtRh40% |

| RTD 3 Wire Input: |

PT100, 50Ω per lead maximum (balanced) |

| Accuracy: |

±0.1% of input range ±1 LSD (T/C CJC better than 1°C) |

| Device Modes: |

PID controller or indicator |

| Control Types: |

50mS, typical |

| Control Operations: |

Full PID with pre-tune, self-tune, manual-tune, or on/off contro |

| Control SSR Driver Outputs: |

Heat-only or heat & coo |

| Output Configuration: |

Drive capability >10V DC in 5000Ω minimum |

| Alarm Types, 3 Available: |

Up to 3 possible, for control and alarm |

| Control & Alarm Relays: |

Process high, process low, SP deviation, band, logical OR / AND |

| Communications: |

Contacts SPDT 2 Amp resistive at 240VAC, >500,000 operations |

| DC Linear: |

2 Wire RS485, 1200 to 19200 Baud, Modbus |

| Triac Outputs: |

0-20mA, 4-20mA, 0-50mV, 10-50mV, 0-5V 1-5V, 0-10V, 2-10V |

| Sampling: |

0.01-1 Amp AC, 20 to 280Vrms, 47 to 63Hz |

| Impedance: |

>10MΩ for Thermocouple and mV ranges, 47KΩ for V ranges and 5Ω for mA ranges |

| Sensor Break Detection: |

<2 seconds (except zero based DC ranges); control O/P's turn off; high alarms activate for T/C and mV ranges; low alarms activate for RTD, mA, or V ranges |

Mechanical & Packaging

| Power Supply: |

100 to 240V 50/60Hz 7.5VA; 20 to 48VAC 7.5VA; 22 to 65V DC 5W |

| Auto or Manual Operation: |

Selectable from panel with bumpless transfer |

| Control Enable: |

Control ON/OFF selectable from keypad |

| Human Interface: |

4 button operation |

| LED Display: |

4 digital 10mm red upper & 8mm green lower plus 5 indicators |

| Scaling: |

Scaling: -1999 to 9999, with adjustable decimal point |

| Front Panel Protection: |

IEC IP66 (Behind panel protection is IP20) |

| Temperature, Operating: |

32 to 130°F (0 to 55°C) |

| Temperature, Storage: |

-4 to 176°F (-20 to 80°C) |

| Relative Humidity: |

20% to 95% RH non-condensing |

Approvals & Self Certifications

| CE: |

Directive 2004/108/EC |

| ISO: |

ISO 9001:2008 production environment |

| UL, ULc: |

Underwriters Laboratory (USA & Canada) |

Ordering Guide for 1496 and 1498 Series Temperature Controllers

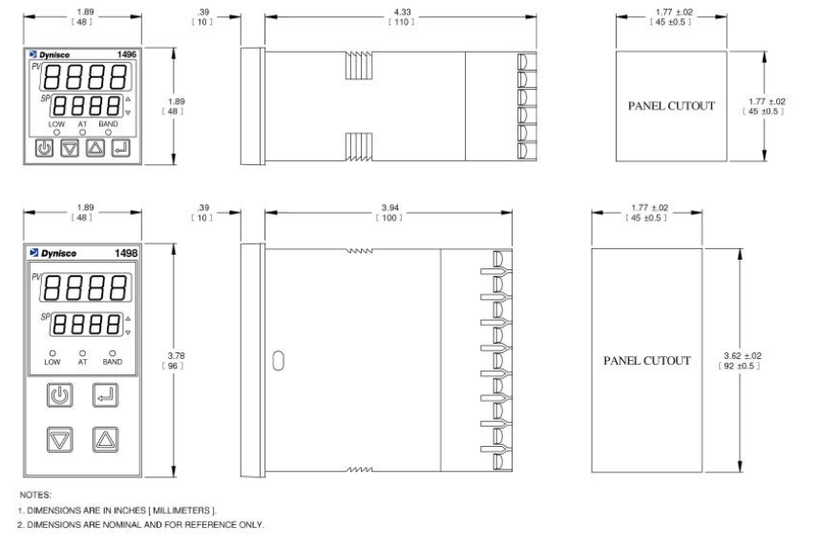

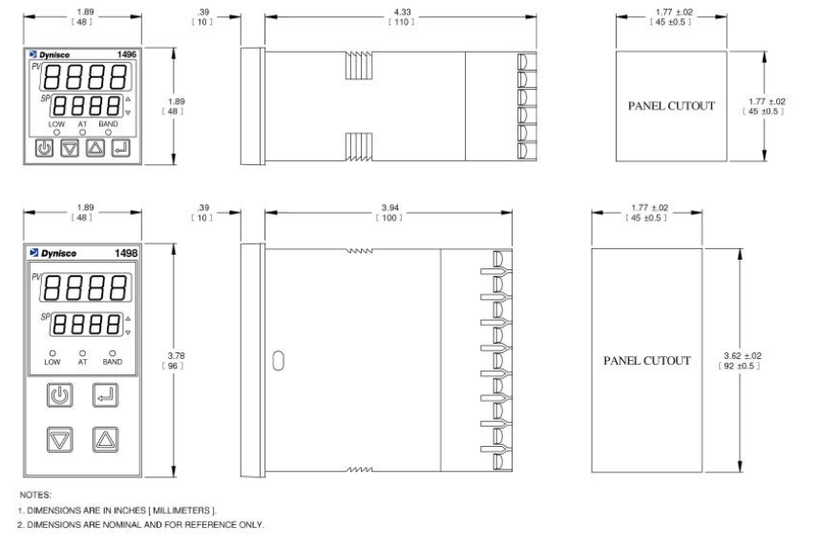

1496 and 1498 series temperature controllers - Dimensions

All dimensions are inches (mm) unless otherwise specified.

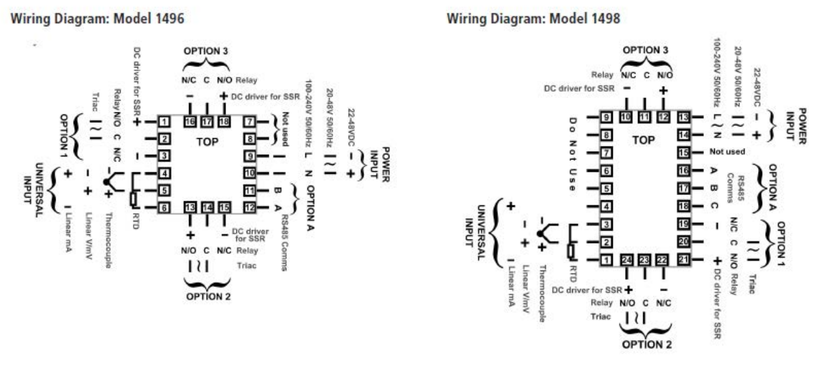

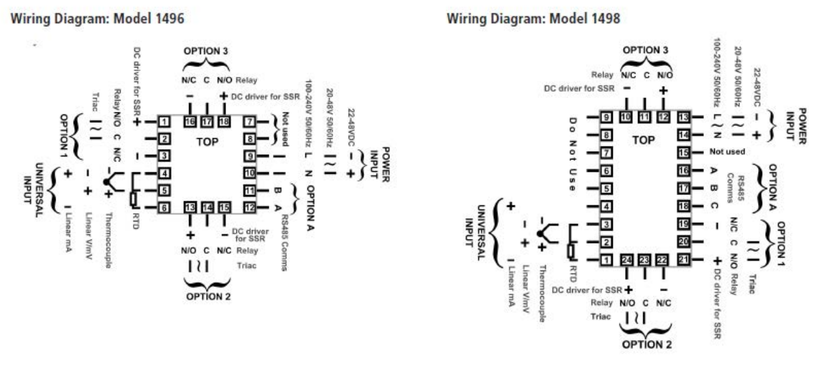

Wiring Label/Rear Terminals

The Dynisco Melt Thermocouple Series DYKE is especially designed to meet the requirements of the polymer industry. The flexible design of this series allows the use in extrusion and injection molding process. The mounting thread is compatible with the threads used for melt pressure measurement. Therefore, the DYMT series is ready for use in most extrusion systems. As an alternative to the DYM T series, the DYKE series offers the possibility of a thermal insultation of the housing. The sensor tip is being ceramically insulated from the housing. These temperature sensors are especially suitable for the use in high abrasive medial.

The DYMT Series features temperature sensors specifically designed to meet the requirements of the polymer industry. The mounting thread is compatibleThe Melt Thermocouple Series DYMT is especially designed to meet the requirements of the polymer industry. The flexible design of this series allows the use in extrusion and injection molding process. The mounting thread is compatible with the threads used for melt pressure measurement.

The Graduated Retractable Melt Thermocouple (GRMT) is used to measure temperatures inside the polymer melt stream. The depth of immersion of the junction into the hot melt stream can be varied from zero to mid-stream during maximum flow and pressure conditions, without removing the sensor from the adapter. Using the graduations on the stem of the temperature sensor allows the user to choose and monitor the specific depth at which the junction is in the melt stream.

The TB422J temperature thermocouple is used to measure the temperature of the polymer melt in extrusion applications. The robust stainless steel probe is made of a fiberglass insulating element and is interchangeable with Dynisco pressure sensors. Thermocouples for measuring the melt temperature are designed and manufactured in accordance with applicable ISA standards with an accuracy traceable to the National Institute of Standard Technology (NIST). National Institute of Standard Technology.

Thermocouples are the most common and widely used devices used to measure temperature. The Dynisco TG422J thermocouples offer a versatile and cost-effective variant, making it a popular choice for extrusion applications in the plastics industry. Available in type J and with a 304 stainless steel construction, the probe can be straight or made at an angle of 45 ° or 90 °. Dynisco thermal thermocouples are designed and manufactured to applicable ISA standards with precision following the National Institute of Standard Technology (NIST).

The TI422J is an alternative thermocouple that allows you to easily and quickly adjust the dive length to suit any application. The thermocouple can be specified with either a 20 cm spring bayonet cap that allows up to 17 cm of adjustable immersion, thanks to a bayonet lock on the flexible armor to allow the full immersion length "B". Dynisco thermal thermocouples are designed and manufactured to applicable ISA standards to the National Institute of Standard Technology (NIST)

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.