Inquiry system

Configure your own product, according to your requirements and needs. If you are not sure about the configuration, make the necessary information in the notes about the building sensor, even a competing one. We will be happy to help you find an alternative Dynisco product. If your request is urgent, let us know, we will do our best to help you resolve this situation as quickly as possible. If we have this information, we are able to offer a model with minor differences and you can have a sensor with you the next day.

Configuration code

Universal pressure and temperature Process Panel Indicator

Dynisco UPR900 Process Indicator

The UPR900 is a compact 1/4 DIN process indicator. The UPR900 can display your choice of engineering units related to a selectable range of input types. Add an optional secondary input for an all-in-one display of polymer melt pressure and temperature. The secondary input can be strain gauge to indicate differential pressure measurement. The UPR900 includes two standard assignable alarms with the option to add a 3rd. The LCD graphical display allows for easy reading of trending graphs with user selectable monochromatic configurations. The UPR900 is easily field-configured, can be programmed remotely via optional Modbus RS-485 or can be programmed with BlueControl software.

The UPR900 is a compact 1/4 DIN process indicator. The UPR900 can display your choice of engineering units related to a selectable range of input types. Add an optional secondary input for an all-in-one display of polymer melt pressure and temperature. The secondary input can be strain gauge to indicate differential pressure measurement. The UPR900 includes two standard assignable alarms with the option to add a 3rd. The LCD graphical display allows for easy reading of trending graphs with user selectable monochromatic configurations. The UPR900 is easily field-configured, can be programmed remotely via optional Modbus RS-485 or can be programmed with BlueControl software.

Performance Characteristics

| Instrument Type: |

Digital, panel-mount PID closed loop indicator |

| Display: |

160 x 80 Monochromatic Graphical LCD with backlight |

| Thermocouple: |

±0.1% of full range, ±1LSD (±1°C for internal CJC if enabled) |

| DC Linear: |

±0.1% of full range, ±1LSD |

| Sampling Time: |

50mS, typical |

Input

| Input: |

Strain gauge, Thermocouple or linear (Vdc, mA) |

| Strain Gauge: |

350 to 5000Ω, 1.4 to 4mV/V, excitation 10V ±7% |

| Linear Input: |

0 to 5Vdc and 0 to 10Vdc, 0 to 20mA and 4 to 20mA |

| Input Signal: |

-25 to 125% full scale (approximately -10mV to +50mV) |

| Input Impedance: |

<10Ω for linear current input >165kΩ for linear voltage input |

| Shunt Calibration: |

With or without resistor (40 to 100%) |

| Digital: |

4 programmable voltage-free contact closure |

Alarm Outputs

| Alarm Type: |

SPST 2A max @ 240Vac resistive load Dual relays have shared common |

| Alarm Number: |

3 standard |

| Alarm Update Time: |

100mS, typical |

Alarm Outputs

| Alarm Type: |

SPST 2A max @ 240Vac resistive load Dual relays have shared common |

| Alarm Number: |

3 standard |

| Alarm Update Time: |

100mS, typical |

Communications

| Type: |

Isolated RS-485 |

| Protocol: |

Modbus RTU |

Mechanical & Packaging Characteristics

| Termination: |

Screw terminals on rear |

| Front Panel: |

IP65 with gasket (IP65 front USB connector) |

| Operating Temp: |

32 to 122°F (0 to 50°C) |

| Storage Temp: |

-4 to 158°F (-20 to 70°C) |

| Humidity: |

85% relative humidity, non-condensing |

| Weight: |

1.43 lbs. (650g) |

Approvals & Certifications

| CE Mark: |

Self-certified to applicable standards |

| Agency Approvals: |

UL |

Power Supply (Mains)

|

Input Power - Mains Version:

|

100 to 240Vac, 50/60Hz switching |

|

Input Power - Low Voltage Version:

|

20 to 48 Vac 50/60Hz 25VA or 22 to 65Vdc 12W |

| Power Consumption: |

15VA, max |

| Transmitter Power Supply: |

24Vdc into 400Ω min, 60mA drive for 2-or 4-wire mA transmitters |

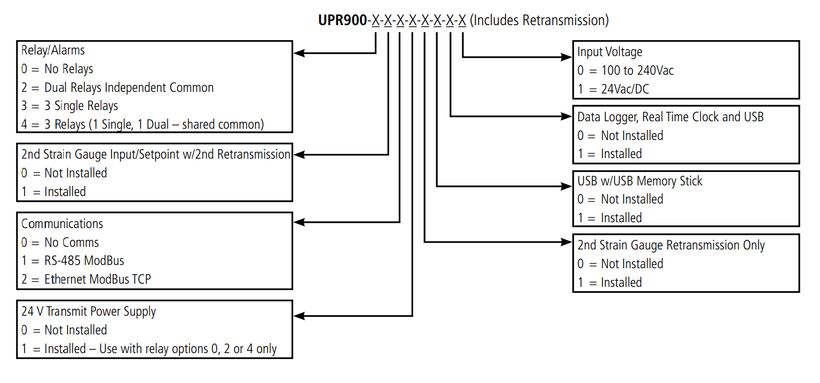

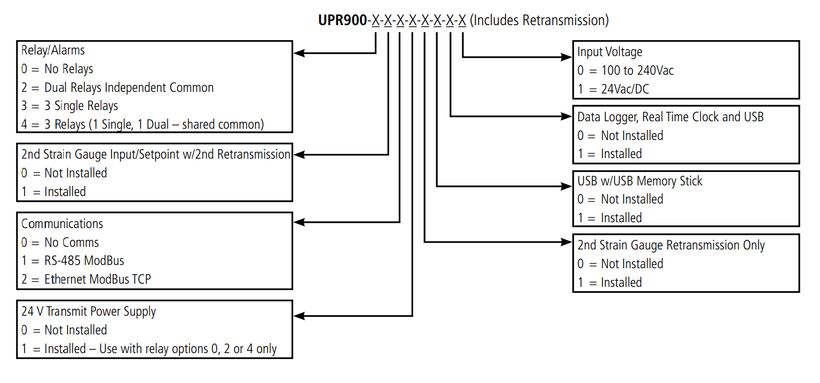

Ordering Guide for UPR900 Panel Indicator

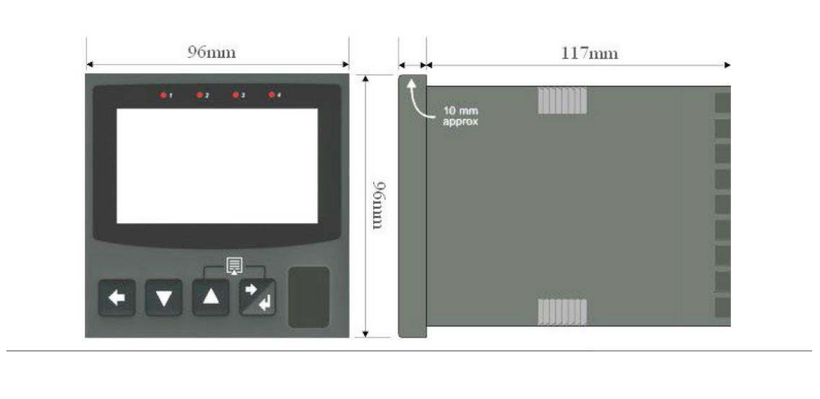

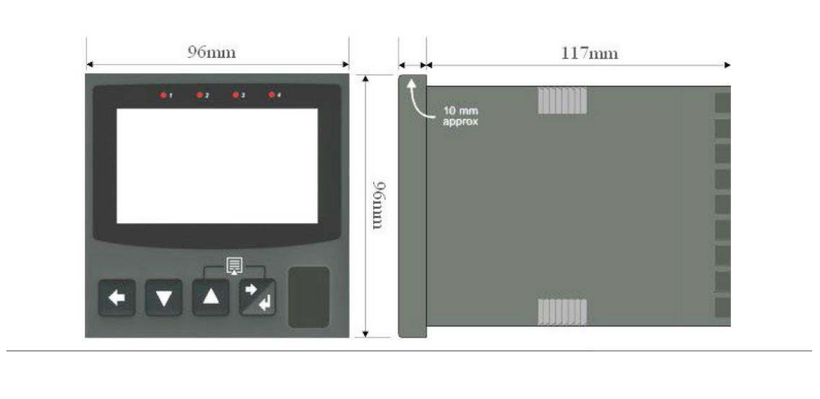

UPR900 - Dimensions

All dimensions are inches (mm) unless otherwise specified.

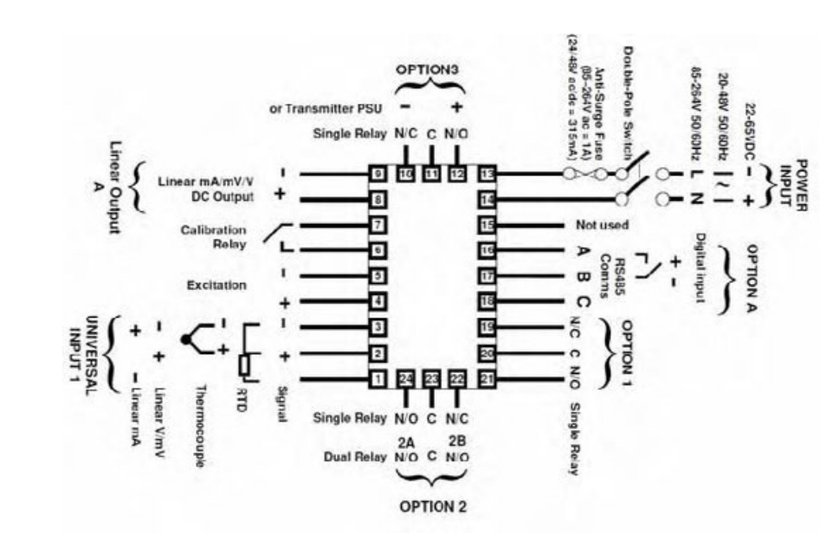

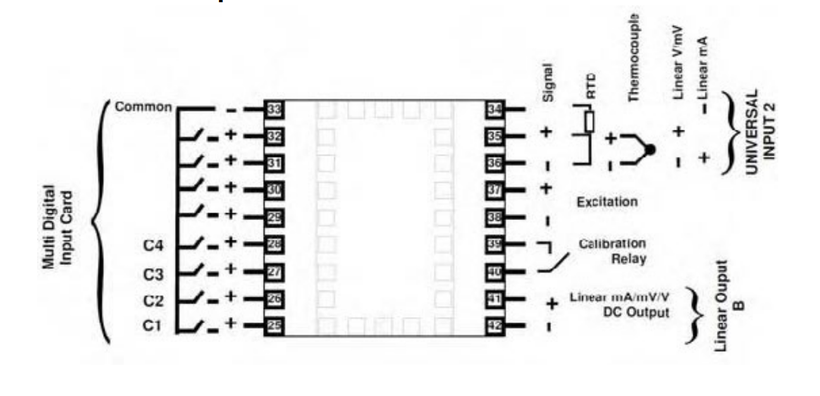

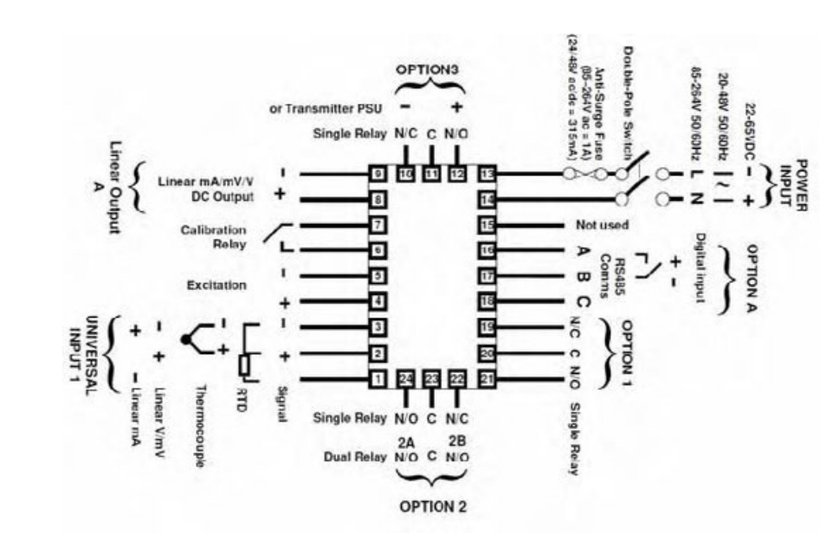

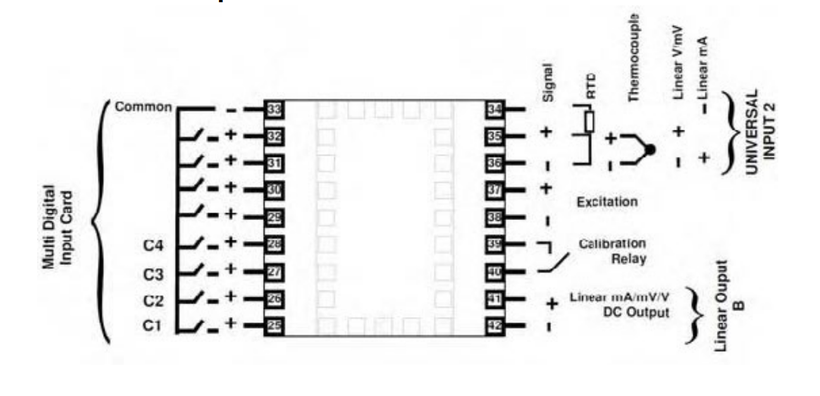

Wiring Label/Rear Terminals

Vertex is more accurate than any other mercury-filled sensor and is ideal for industrial applications that require low pressure.

The pressure range for Vertex is now available from 250 - 10,000 PSI. Not only is this an overall improvement to one’s process, but it helps with customers that are focused on sustainability and zero-waste.

Trusted for Quality, Reliability and Accurate Performance at an Affordable Price

Dynisco's Echo™ Series of melt pressure sensors offer quality performance and value for plastic processing utilizing standard configurations and pressure ranges. Echo sensors are designed to meet customer requirements by providing a combination of economic value and performance for general extrusion applications while providing a ±0.2% repeatability when measuring process pressures. Use Echo Series sensors when the application requires a quality measurement for optimized control, but not the costs of all the extra features.

MDA435 - Sensor with flexible and exposed capillary

The sensors of this series MDA435 have a flexible capillary with an exposed mounting tip, which is used in an area where it is not possible to install a standard sensor with a flexible capillary and a rigid stem. Individual models have different accuracy. Model 435 has an accuracy of 0.50% of the pressure range. Power supply with 10-12 V DC and membrane made of 15-5 PH material and coated with DyMAX layer. The length of the flexible capillary can be optionally configured.

MDA467 - Sensor with flexible and exposed capillary

The sensors of this MDA467 series have a flexible capillary with an exposed mounting tip, which is used in an area where it is not possible to install a standard sensor with a flexible capillary and a rigid stem. Individual models have different accuracy. Model 467 has an accuracy of 1.00% of the pressure range. Power supply with 10-12 V DC and membrane made of 15-5 PH material and coated with DyMAX layer. The length of the flexible capillary can be optionally configured.

MDA 410 - Sensor with rigid stem

MDA 412 - Sensor with rigid stem and flexible stem

TDA 412 - Combined sensor with rigid stem, flexible stem and built-in temperature sensor

Mercury-free sensors with 10-12 Vdc power supply. They meet the most stringent conditions controlled by the FDA - the Food and Drug Administration and the USDA. The membrane is made of Inconel 718. The length of the rigid rod and flexible capillary can be made and adjusted to the required size.

PT420A - Sensor with rigid stem

PT422A - Sensor with rigid stem and flexible stem

TPT432A - Combined sensor with rigid stem, flexible stem and built-in temperature sensor

PT420A Series transducer is a ±0.25% sensor ideal for melt pressure applications requiring high accuracy, simple installation, repeatability and reliability.

PT460E - Sensor with rigid stem

PT462E - Sensor with rigid stem and flexible stem

TPT463E - Combined sensor with rigid stem, flexible stem and built-in temperature sensor

Sensors with high accuracy ± 1.0% in optional design. Power supply via 10-12 V dc. Membrane made of 15-5 PH material and coated with DyMAX layer. The length of the fixed rod can be made and adjusted to the required size. 6-pin bayonet connector.

PT435A - Sensor with flexible and exposed capillary

The PT435A series model have been designed for applications where installation space is extremely limited. The exposed part of the capillary allows a bend with a small radius of 3 mm. The specially developed design of the sensor tip facilitates the installation of the sensor in very cramped and confined spaces, where it is not possible to install a standard sensor with a fixed rod or flexible capillary.

PT467E - Sensor with flexible and exposed capillary

The PT467E models have been designed for applications where installation space is extremely limited. The exposed part of the capillary allows a bend with a small radius of 3 mm. The specially developed design of the sensor tip facilitates the installation of the sensor in very cramped and confined spaces, where it is not possible to install a standard sensor with a fixed rod or flexible capillary.

PT410 - Sensor with rigid stem

PT412 - Sensor with rigid stem and flexible stem

TPT412 - Combined sensor with rigid stem, flexible stem and built-in temperature sensor

The PT 41x series is a sensor with ±0.25% accuracy, which is ideal for food or medical applications. Its alternative filling (NaK), which replaces mercury.

PT415D - Washable sensor with rigid stem and NaK filling.

The PT415D pressure transmitter with accuracy of better than ±0.5% is the ideal choice for food and medical applications that require high accuracy and easy maintenance. It is a washable sensor with insulated wiring type 1/2-14 NPT or an optional 6-pin hermetically insulated bendix connector. PT 415D contains a high temperature fill (NaK, sodium potassium) and an Inconel membrane. Meets FDA and USDA hygiene regulations and requirements.

PT418 - Sensor with rigid stem

PT419 - Sensor with rigid stem and flexible stem

TPT419 - Combined sensor with rigid stem, flexible stem and built-in temperature sensor

Model PT418 | PT419 | TPT419 Better than ±0.5% accuracy uses mineral oil as a filler, which meets the requirements of the FDA and USDA and at the same time allows accurate pressure sensing in processes where it is not possible to use mercury fillings. These models are ideal for medical and food or packaging applications.

PT4194 Sensors provide an industry standard 4-20 mA amplified signal designed to work with DCS and PLC.

It is a sensor with ± 0.5% accuracy ideal for the food or pharmaceutical industry requiring easy installation, repeatability and reliability. It is filled with mineral oil that meets the requirements of FDA 21 CFR 178.3620, 21 CFR 172.878 and 21 CFR 573.680.

PT4195 sensors provide a standard 0-5Vdc output signal designed to work with DCS and PLC.

It is a sensor with ± 0.5% accuracy ideal for the food or pharmaceutical industry, requiring easy installation, repeatability and reliability. It is filled with mineral oil that meets the requirements of both the USDA and the FDA.

PT4196 sensors provide a standard 0-10Vdc output signal designed to work with DCS and PLC.

The PT4196 is a ± 0.5% accuracy sensor ideal for applications in the food and pharmaceutical industries requiring easy installation, repeatability and reliability. The output signal represents 0-10. The alternative filling of the sensor in the form of oil for the food industry meets the requirements set by the USDA and the FDA.

PT130 = 3 mV/V

PT140 = 0-5 VDC

PT150 = 0-10 VDC

PT160 = 4 - 20 mA

This range of hydraulic sensors is designed to measure pressure in injection molding applications. It has a very good resistance to cyclic pressure, which is characteristic of these applications and provide information on the change of the hyd profile. pressure together with information on the stability of the injection system

Model PT4674 is a special variant of the pressure sensor with flexible capilary and exposed capillary, which has an output signal of 4-20 mA. It is used wherever a conventional sensor with a fixed rod or flexible capillary cannot be installed due to lack of space.The accuracy of this sensor is better than ±0.5%.

Model PT4675 is a special variant of the pressure sensor with flexible capillary and exposed capillary, which has a 0-5 VDC output signal and is used wherever a conventional fixed rod or flexible capillary sensor cannot be installed due to lack of space. The accuracy of this sensor is better than ±0.5%.

Model PT4676 is a special variant of the pressure sensor with flexible capillary and exposed capillary, which has a 0 to 5 Vdc, 1 to 6 Vdc, 0 to10 Vdc, 1 to 11 Vdc outputs signal and is used wherever a conventional fixed rod or flexible capillary sensor cannot be installed due to lack of space. The accuracy of this sensor is better than ±0.5%.

MDT420 - Sensor with rigid stem

MDT422 - Sensor with flexible capillary.

TDT432 - Sensor with flexible capillary and temperature sensor.

Sensor with integrated amplifier (signal converter). Scanning accuracy better than 0.50% of range. Power supply via 10-36 Vdc. Membrane made of 15-5 PH material and coated with DyMAX®. The length of the fixed rod can be made and adjusted to the required size.

MDT460 - Sensor with rigid stem

MDT462 - Sensor with flexible capillary.

TDT463 - Sensor with flexible capillary and temperature sensor.

Sensor with integrated amplifier (signal converter). Scanning accuracy better than 1.00% of range. Power supply via 10-36 Vdc. Membrane made of 15-5 PH material and coated with DyMAX®. The length of the fixed rod can be made and adjusted to the required size.

MDT435 - Sensor with flexible and exposed capillary

Sensor with an amplifier (signal converter) in a version with flexible capillary and exposed membrane. Scanning accuracy better than 0.50% of the range. Power supply via 10-36 Vdc. Membrane made of 15-5 PH material and coated with DyMAX®. The length of the fixed rod can be made and adjusted to the required size.

MDT467 - Sensor with flexible and exposed capillary

Sensor with amplifier (signal converter) in version with flexible capillary and exposed membrane. Scanning accuracy better than 1.00% of range. Power supply via 10-36 Vdc. Membrane made of 15-5 PH material and coated with DyMAX®. The length of the fixed rod can be made and adjusted to the required size.

MDA420 - Sensor with rigid stem

MDA422 - Sensor with rigid stem and flexible capillary

TDA 432 - Combined sensor with rigid stem, flexible capillary and built-in temperature sensor

The sensors of this 42x series are specific with an 6-pin threaded connector Bendix and an accuracy of ±0.25% of the pressure range. Power supply via 10-12 V DC. Membrane made of 15-5 PH material and coated with DyMAX layer. The length of the fixed rod and the flexible capillary can be optionally configured.

MDA 460 - Sensor with rigid stem

MDA 462 - Sensor with rigid stem and flexible stem

TDA 463 - Combined sensor with rigid stem, flexible stem and built-in temperature sensor

The sensors of this 46X series are specific with a 6-pin bayonet connector and an accuracy of ±0.5% of the pressure range. Power supply via 10-12 V DC. Membrane made of 15-5 PH material and coated with the DyMAX layer. The length of the rigid stem and the flexible capillary can be optionally configured.

PT467XL- Pressure sensor with flexible and exposed capillary In a version with a more durable membrane(XL).

The PT467XL series of pressure transmitters are the ideal choice for applications with high accuracy and minimal mounting space. The PT 467XL models have an accuracy of ± 0.5% of range and an exposed capillary with a diameter of 1.5 mm, which allows bending in a radius of 1/16 inch. The sensors are supplied with a Dymax® membrane, which ensures an increase in wear resistance and thus a longer service life. Sensors marked XL have a protector (flexible capillary) up to the tip of the sensor.

Mercury-free. Trusted for Quality, Reliability and Accurate Performance at an Affordable Price

Dynisco's Echo™ Series of melt pressure sensors offer quality performance and value for plastic processing utilizing standard configurations and pressure ranges. Echo sensors are designed to meet customer requirements by providing a combination of economic value and performance for general extrusion applications while providing a ±0.2% repeatability when measuring process pressures. Use Echo Series sensors when the application requires a quality measurement for optimized control, but not the costs of all the extra features.

The PT4654XL models represent an optimal solution for precise melt pressure measurement in nozzles or distribution channels within injection molding applications.

The flexible capillary extends from its electronic housing to the positioned tip in the machine melt, ensuring exceptional durability and prolonged sensor lifespan thanks to its robust construction.

The PT4655XL models represent an optimal solution for precise melt pressure measurement in nozzles or distribution channels within injection molding applications.

The flexible capillary extends from its electronic housing to the positioned tip in the machine melt, ensuring exceptional durability and prolonged sensor lifespan thanks to its robust construction.

The PT4656XL models represent an optimal solution for precise melt pressure measurement in nozzles or distribution channels within injection molding applications.

The flexible capillary extends from its electronic housing to the positioned tip in the machine melt, ensuring exceptional durability and prolonged sensor lifespan thanks to its robust construction.

Dynisco PT139 and PT139A pressure sensors are designed to measure hydraulic pressure in extreme conditions for testing vehicles, stands and other hydraulic and pneumatic applications. These sensors withstand cyclic pressure and provide excellent performance during demanding industrial conditions.

The PT199 pressure sensor is designed to measure pressure on turbine systems. Provides information on pressure or temperature in gas or fuel systems such as gas turbines to regulate gas or fuel flow.

The Dynisco PT303 pressure transmitter is designed for all pressure applications in potentially explosive atmospheres. With high performance and a wide range of pressures, it offers trouble-free operation and flexibility to suit all your requirements.

The Dynisco PT311JA Washable Pressure Sensor is designed for applications requiring a zero volume pressure port. The recessed diaphragm improves the frequency response. The PT311JA has a full 3 mV / V output signal and offers reliable and accurate pressure measurement of gases, viscous liquids.

The Dynisco PT 375 pressure transmitter is designed for applications requiring a zero volume pressure port, fast response time and strict cleanliness standards. The high-pressure metal-to-metal seal offers reliable pressure measurement of sludges, viscous liquids and other media that can be homogenized.

The high-temperature EPR3 melt pressure sensor from Dynisco is offered as an alternative to the PT420 and PT460 series. The solid rod design is suitable for applications where the use of a filling medium may not be appropriate, such as applications for the food and pharmaceutical industries and the production of photographic films. The EPR3 model is available in various pressure variants.

The EPR4 series are sensors with ± 0.5% accuracy ideal for food or medical applications requiring easy installation, repeatability and reliability. Technology Push Rod design is especially suitable for food or medical applications with the possibility of filled systems. EPR4 provide an industry standard in the form of an amplified 4-20 mA signal designed to work with DCS and PLC. The EPR4 model is available in various pressure variants.

The Dynisco Melt Thermocouple Series DYKE is especially designed to meet the requirements of the polymer industry. The flexible design of this series allows the use in extrusion and injection molding process. The mounting thread is compatible with the threads used for melt pressure measurement. Therefore, the DYMT series is ready for use in most extrusion systems. As an alternative to the DYM T series, the DYKE series offers the possibility of a thermal insultation of the housing. The sensor tip is being ceramically insulated from the housing. These temperature sensors are especially suitable for the use in high abrasive medial.

The DYMT Series features temperature sensors specifically designed to meet the requirements of the polymer industry. The mounting thread is compatibleThe Melt Thermocouple Series DYMT is especially designed to meet the requirements of the polymer industry. The flexible design of this series allows the use in extrusion and injection molding process. The mounting thread is compatible with the threads used for melt pressure measurement.

The Graduated Retractable Melt Thermocouple (GRMT) is used to measure temperatures inside the polymer melt stream. The depth of immersion of the junction into the hot melt stream can be varied from zero to mid-stream during maximum flow and pressure conditions, without removing the sensor from the adapter. Using the graduations on the stem of the temperature sensor allows the user to choose and monitor the specific depth at which the junction is in the melt stream.

The TB422J temperature thermocouple is used to measure the temperature of the polymer melt in extrusion applications. The robust stainless steel probe is made of a fiberglass insulating element and is interchangeable with Dynisco pressure sensors. Thermocouples for measuring the melt temperature are designed and manufactured in accordance with applicable ISA standards with an accuracy traceable to the National Institute of Standard Technology (NIST). National Institute of Standard Technology.

Thermocouples are the most common and widely used devices used to measure temperature. The Dynisco TG422J thermocouples offer a versatile and cost-effective variant, making it a popular choice for extrusion applications in the plastics industry. Available in type J and with a 304 stainless steel construction, the probe can be straight or made at an angle of 45 ° or 90 °. Dynisco thermal thermocouples are designed and manufactured to applicable ISA standards with precision following the National Institute of Standard Technology (NIST).

The TI422J is an alternative thermocouple that allows you to easily and quickly adjust the dive length to suit any application. The thermocouple can be specified with either a 20 cm spring bayonet cap that allows up to 17 cm of adjustable immersion, thanks to a bayonet lock on the flexible armor to allow the full immersion length "B". Dynisco thermal thermocouples are designed and manufactured to applicable ISA standards to the National Institute of Standard Technology (NIST)

Software for new UPR indicators and ATC controllers, which simplifies setup and configuration. The big advantage is OFF-LINE configuration and setting simulation, which reduces the risk of interrupting ongoing operations. With a PC, setup is even easier than with next-generation controllers and indicators.

PT4605 - Sensor with rigid stem

PT4625 - Sensor with rigid stem and flexible stem

TPT4635 - Combined sensor with rigid stem, flexible stem and built-in temperature sensor

The PT46X5 Series transmitter is a +/- 0.5% sensor ideal for general purpose melt pressure measurements requiring simple installation, repeatability and reliability. The PT46X5 transmitters provide the industry standard 0 - 5 Vdc amplified signal designed to work with DCS and PLCs, 1 - 6 Vdc outputs are also available.

PT4604 - Sensor with rigid stem

PT4624 - Sensor with rigid stem and flexible stem

TPT4634 - Combined sensor with rigid stem, flexible stem and built-in temperature sensor

The PT46x4 Series pressure sensor is a ±0.5% sensor ideal for general melt pressure measurements requiring simple installation, repeatability and reliability. The PT46x4 sensor provides the industry standard 4-20 mA amplified signal designed to work with DCS and PLCs.

PT4606 - Sensor with rigid stem

PT4626 - Sensor with rigid stem and flexible stem

TPT4636 - Combined sensor with rigid stem, flexible stem and built-in temperature sensor

The PT46X6 Series transmitter is a ±0.5% sensor ideal for general purpose melt pressure measurements requiring simple installation, repeatability and reliability. The PT46X6 transmitters provide the industry standard 0 - 10 Vdc amplified signal designed to work with DCS and PLCs, 1 - 11 Vdc outputs are also available.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.