Extrex-Y adapter

Twin outlet gear pump for complex extrusion applications

The extrex⁶ Y-Adaptor unites two extrex x⁶ class gear pumps to ensure optimum efficiency and cost-effectiveness in extrusion systems. The extrex⁶ Y-Adaptor can be used with an extruder to feed two different die packs with a separate, constant melt stream each. Separate discharges from the individual gear wheel pairs are guaranteed thanks to the design and can be adjusted by changing the speed of the individually controlled drives. The extrex x⁶ class gear pump portfolio allows customers to choose between different thrust pieces to suit their application.

Inquiry system

Configure your own product according to your requirements and needs. If you are unsure of the configuration, provide us in the notes the necessary information about the existing sensor or product, even a competitor. We will be happy to help you find an alternative MAAG products. If your request is urgent, let us know. We will do our best to help you resolve this situation to your satisfaction as quickly as possible. If we have all the information, we are able to offer a model with minor differences.

If you need more information do not hesitate to contact us.

Configuration code

TECHNICAL DATA

|

Viscosity [MPas] |

Až 30 000 000 |

|

Temperature [° C] |

Až 350 |

SELECTION OF TYPICAL PUMPED MEDIA

| |

Polyolefiny

|

| |

Polyestery

|

| |

Polyamidy

|

|

Polycarbonates |

|

Styrene polymers |

|

Expandable polystyrene |

|

ABS/SAN |

|

Fluoro polymers |

|

TPE |

|

Other polymers on request |

|

Paints and varnishes |

|

Waxes and paraffins |

|

Mineral oils and fats |

|

Fuels |

|

Petrochemical products |

|

Lubricating oil |

OPTIONS

| |

Different classes of will

|

| |

Liquid heating system with filtration

|

|

Selection of materials for a specific application |

|

Pressure and temperature sensor holes in the housing |

|

Selection of materials for each application |

|

Cooling for shaft seals |

|

Special types of seals |

ACCESSORIES

| |

Support and base frames

|

| |

Adapter flange

|

|

Sensors |

|

Regulation, complex expac® solution |

|

Drive components |

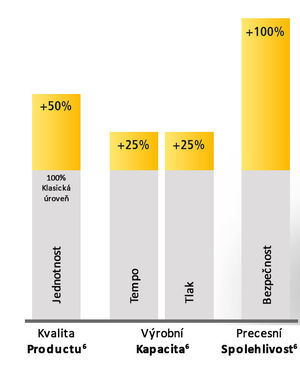

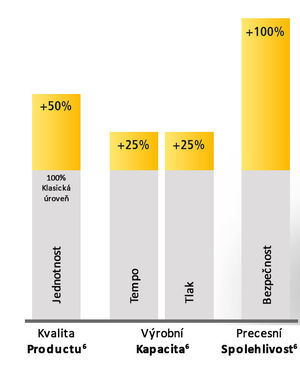

The value of the 6th generation

Simplified linearity

Elimination of incoming pulsations to maximize product uniformity

Protection of processed material

Minimized backflow volume to accelerate polymer flow

6th generation performance

Endurance shaft

Improved resistance to differential pressure increase

Top speed

Excellent flow capacity for increased productivity

Reliability of the 6th generation

Balanced bearings

Unique self-centering shafts

Maximize process stability

When it comes to manufacturing profiles and dealing with strainers, high requirements are placed on pumping consistency and extrusion lines. The new gear pump series extrex⁶ RV/RB from MAAG raises the performance of gear pumps for elastomer extrusion to new levels in terms of both economy and processing technology. Product quality is guaranteed by a stable discharge, the lowest tolerance deviations and achieving process stability in quick time.

Elastomeric processing requires positive displacement devices that gentle convey high viscosity rubber through the system. Specifically designed, low compression tooth design allow the extrex⁶ ER transfer, booster or metering gear pump to achieve both high pressure and low shear.

The rubber compound is conveyed with a constant, precise flow even at high discharge pressures – and this also for extremely dry or sticky compounds, where former pump generations reached their limits due to scorch. Additionally, their anyway high efficiency and long life span will extend unrivaled due to reduced internal friction.

Suitable for Extrusion

Extrusion operations require extremely reliable gear pump systems with high output consistency and a configuration to suit each application.

The modular design of extrex® gear pumps easily meets the requirements for these diverse applications.

The extrex⁶ GU gear pump is a general use design that elevates your process to the next level. With the new x⁶ class design you have additional benefi ts compared to the classic gear pump designs.

All pumps are available with ST design (flow optimized) and with the 5R design (Retrofit flange design classic pump).

Suitable for Masterbatch, Compounding, Recycling, Extrusion

The extrex6 EP gear pump is an intermediate pressure solution for applications requiring higher pressure, greater load bearing considerations for low lubricity products. With the new x6 class design you have additional benefits compared to the classic gear pump designs.

Suitable for Extrusion

The extrex⁶ SP gear pump is a high pressure gear pump for applications dictating high pressures and loads. With the new x⁶ class design you have additional benefits compared to the classic gear pump designs.

All Pumps are available with ST design (flow optimized) and with the 5R design (Retrofit flange design classic pump).

Extrusion operations require extremely reliable gear pump systems with high output consistency and a configuration to suit each application. The modular design of extrex® gear pumps easily meets the requirements for these diverse applications.

Suitable for Extrusion

Extrusion operations require extremely reliable gear pump systems with high output consistency and a confi guration to suit each application.

The modular design of extrex® gear pumps easily meets the requirements for these

diverse applications.

The extrex⁶ MP is a high pressure gear pump for the most demanding thermoplastic applications. With the new x⁶ class design you have additional benefi ts compared to the classic gear pump designs.

The flange design ST is already the same as the classic trudex, so there is no need to change process connections when replacing classic trudex pumps.

Suitable for Extrusion