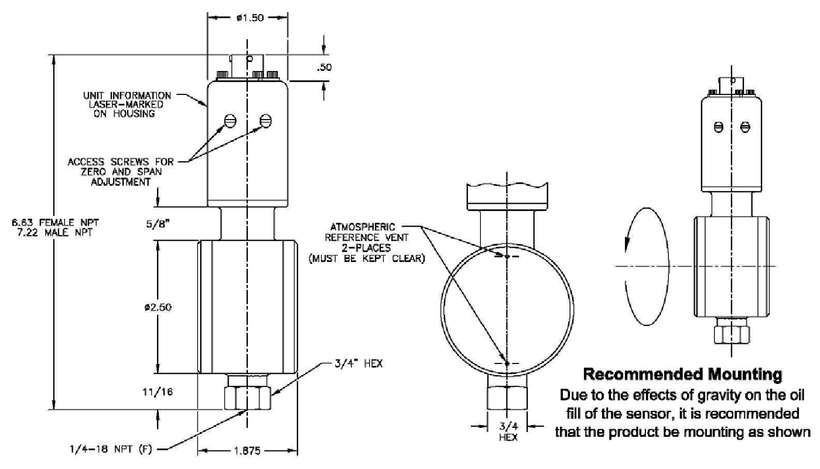

Model 244 Pressure Transducer

The Model 244 offers a 0 to 5 Vdc signal. Using our variable capacitance technology, the Model 244 transducer provides extreme overpressure protection up to 500 PSI. This sensor design provides standard accuracy of <±0.15% FSO. The unit also offers standard temperature performance to ±2%/100° F with an improved option to±1%/100° F.

All wetted surfaces of the X44 Series are constructed with 316 stainless steel, making them ideal for wet/wet applications.In environmental test chambers, these surfaces withstand contaminants such as water vapor, oil, exhaust or mists.

Atmospheric reference is specially constructed to withstand the ingress of moisture, ensuring accurate pressure measurement.

Model 244 features an internal calibration circuit for easy field set-up, a quick disconnect electrical connection and external zero and span controls. These features allow you to calibrate the transducer without an external pressure source and eliminate the need to send the unit to a metrology lab for calibration.

Inquiry system

Configure your own product according to your requirements and needs. If you are unsure of the configuration, provide us in the notes the necessary information about the existing sensor or product, even a competitor. We will be happy to help you find an alternative Viatran product. If your request is urgent, let us know. We will do our best to help you resolve this situation to your satisfaction as quickly as possible. If we have all the information, we are able to offer a model with minor differences, which is in stock and you can have another product available the next day.

If you need more information do not hesitate to contact us.

Viatran Configuration Code:

PERFORMANCE

| Full Scale Pressure Ranges | 0-5, 10, 20, 50, 100, 300, 750" W.C. 0-15, 50, 100 PSIG |

|

| Nonlinearity (Best Fit Straight Line) | ≤±0.15% FSO | |

| Hysteresis & Repeatability | ≤±0.10% FSO | |

| Full Scale Output (FSO) | 5 Vdc at 70° F | |

| Long Term Stability | ≤±0.2% FSO per 6 months | |

| Zero Shift After 500 PSI Overload | ≤± 0.1% FSO | |

| Compensated Temperature Range | 70°F to 170°F (21°C to 76°C) | |

| Ambient Operating Temperature Range | 0° F to +250° F | |

| Storage Temperature Limits | -40°F to 250°F (-40°C to 121°C) | |

| Temperature Effect on Zero | <± 2.0% FSO per 100° F | |

| Temperature Effect on Span | <± 2.0% FSO per 100° F |

ELECTRICAL

|

Supply Voltage:

|

10 to 42 Vdc

|

|

|

Power Supply Regulation:

|

≤±0.1% FSO change over the supply voltage range

|

|

|

Output Signal:

|

0 to 5 Vdc standard (see option DM)

|

|

| Output Loading | 3000 Ohms minimum | |

| Zero Adjustment | ± 10 % FSO min | |

| Span Adjustment | ± 10% FSO min | |

| Calibration Signal | 80% of the FSPR, by shorting pins E & F | |

| Calibration Signal Accuracy | ≤±0.5% FSO | |

| Circuit Protection | Reverse polarity protected | |

| Insulation Resistance | <1nS | |

| Response Time | From 0.2 Sec for 5" W.C. range down to 0.008 Sec for 100 PSI range. Faster response available with NF option. | |

| Electrical Connection | Bendix PT02E-10-6P, mates PT06E-10-6S (SR) | |

| Pin Outs | Pin A + Power Pin B - Power Pin C + Signal Pin D - Signal Pin E Calibrate Pin F Calibrate |

MATERIALS OF CONSTRUCTION

|

Wetted Parts

|

316 stainless steel

|

|

|

Housing

|

304 and 316 Stainless Steel with an Aluminum alloy, black zinc-cobalt plated electrical connector

|

|

|

Weight

|

3.6 lbs.

|

|

| Identification | Laser etched onto body |

MECHANICAL

|

Pressure Connection:

|

1/4" - 18 NPT female

|

|

|

Proof Pressure:

|

500 PSI

|

|

|

Burst Pressure:

|

1000 PSI

|

|

| Position Sensitivity | ≤ ± 1.0” W.C. in any ≤ ± 1.0” W.C. in any orientation | |

| Shock & Vibration | ≤ ± 1.0% FSO per G for 50 Hz to 200 Hz along any axis | |

| Fill Fluid | Dow DC200 Silicone oil | |

| Mounting | .May be supported by process piping or by optional mounting bracket |