Model 248 Pressure Transducer

The “48” Series is made to withstand overloads and severe pressure spikes that can offset, weaken or destroy other sensors. The minimum 3X overpressure rating on the X48 means better than 0.15% accuracy while still offering a response time of less than a millisecond. It’s designed to provide years of reliable, repeatable service.

Typical Applications:

• Engine test stands

• Production test stands

• Hydraulic

• Compressors & Pumps

• Rolling mills

• Die Casting

Contact our Application Engineers today to customize this unit to meet your specific needs.

Inquiry system

Configure your own product according to your requirements and needs. If you are unsure of the configuration, provide us in the notes the necessary information about the existing sensor or product, even a competitor. We will be happy to help you find an alternative Viatran product. If your request is urgent, let us know. We will do our best to help you resolve this situation to your satisfaction as quickly as possible. If we have all the information, we are able to offer a model with minor differences, which is in stock and you can have another product available the next day.

If you need more information do not hesitate to contact us.

Viatran Configuration Code:

0-5 Vdc, 0- 3 to 15K psi, High Overpressure Protection

All welded stainless steel construction combined with sensors that are hermetically sealed with no adjustment controls provide an airtight and watertight transducer preventing contamination from the application environment. The “48” Series is made to withstand overloads and severe pressure spikes that can offset, weaken or destroy other sensors. The minimum 3X overpressure rating on the X48 means better than 0.15% accuracy while still offering a response time of less than a millisecond. It’s designed to provide years of reliable, repeatable service.

Performance characteristics

| Full Scale Pressure Ranges | 0-15 thru 0-200 PSIA (0-1.0 thru 0-13.7 bar) 0-3 thru 0-15K PSIG, PSIS (0-0.2 thru 0-1034 bar) 0-15 PSIV* (0-1.03 BarV) |

|---|---|

| Accuracy (combined linearity, hysteresis & repeatability) | 0-200 PSI (0-13.7 bar)≤±0.25% FSO 300 - 15K PSI (20-1034 bar)≤ 0.15% |

| Full Scale Output (FSO) | 5 Vdc ±1% |

| Resolution | Infinite |

| Long Term Stability | ≤0.5% FSO per 6 months |

| Compensated Temperature Range | 70°F to 170°F (21°C to 77°C) |

| Ambient Operating Temperature Range | -40°F to 185°F (-40°C to 85°C) |

| Storage Temperature Limits | -40°F to 250°F (-40°C to 121°C) |

| Temperature Effect on Zero | ≤± 1 % FSO per 100°F |

| Temperature Effect on Span | ≤± 1 % FSO per 100°F |

| * For PSIV and Compound Range units |

Temperature Effect on Zero Compensated Temperature Range |

Electrical characteristics

| Supply Voltage | 9 to 30 Vdc |

|---|---|

| Power Supply Regulation Effect | ≤±0.05% FSO per volt over the supply voltage range |

| Output Signal | 0 - 5 Vdc |

| Circuit Protection | Reverse polarity protected |

| Insulation Resistance | <5 nSec |

| Response Time | ≤1 mSec for 10% to 90% FSO |

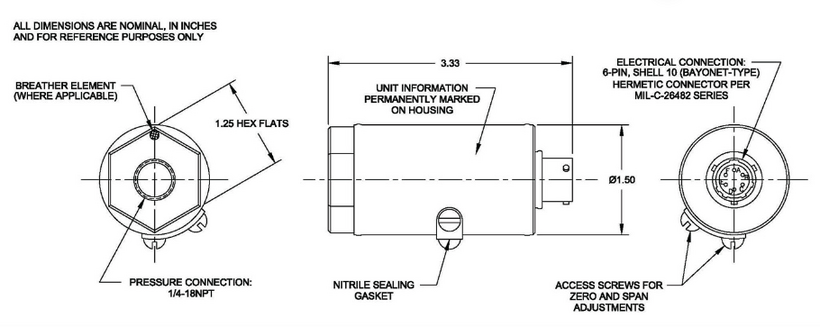

| Electrical Connection | 6 pin hermetic, bayonet-style, 303 SST weldmount connector |

| Pin Outs |

Pin A+ Power

Pin B- Power

Pin C+ Signal

Pin D- Signal

Pin ENo connection

Pin FNo connection

|

Materials of Construction

| Wetted Parts |

0-3 thru 200 PSI (0-0.2 thru 13 bar) 316 Stainless Steel >200 PSI (>13 bar)15-5PH stainless steel |

|---|---|

| Housing | 316 / 304L Stainless Steel |

| Weight | 10 oz (283 g) |

| Identification | Laser etched onto body |

Mechanical characteristics

| Pressure Connection |

1/4" - 18 NPT female |

|---|---|

| Proof Pressure | 3 times FSPR or 20K PSI (1378 bar), whichever is less |

| Burst Pressure | 5 times FSPR or 45K PSI (3102 bar), whichever is less |

| Pressure Cavity Volume | 3 mL without fittings |

| Mounting | May be supported by process piping |

Options

ELECTRICAL CONNECTION

BH

BI

BZ

ZU

ZY

ALTERNATE PRESSURE PORTS

WG

YC

YD

YG

YK

YU

PERFORMANCE OPTIONS

DE

DG

DH

DM

DQ

EA

NH

NJ

PW

Note:

Drawings

Certificates & Approvals

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety. More information

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety. More information

E-Learning

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results. More information

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results. More information

Instructional Videos

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support. More information

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support. More information

Relevant Articles

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support. More information

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support. More information