Melt Flow Indexer Accessories - Black Box

Accessories can be ordered separately or as a complete set in the form of a complete "black-box" case.

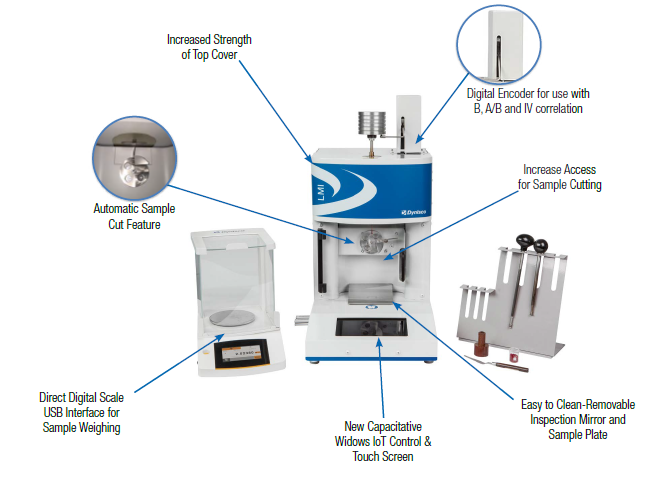

This LMFI5500 series Melt Flow Indexer allows the measurement of most rheological parameters of thermoplastics including IV for PET. The LMFI 5500 series is one of the most accurate equipment of the type in the world. The intuitive controls make it easy to use, it has an expert mode for experienced operators that significantly speeds up the measurement process, and sophisticated features and technologies ensure the highest possible measurement accuracy. Gravity correction and dual zone heating not only meet but exceed the requirements of the latest ISO1133-2 valid standard. This model is perfect for quality control in a laboratory, institutes or universities where accuracy really matters. Try the LMFI 5500 and get a reliable and accurate instrument that will allow you to improve the quality of your products.

It will surprise you with its user-friendly environment and easy maintenance, while keeping maximum precision. In addition, if you later decide to expand your equipment, our service technicians will simply install the necessary modules on your site. With the LMFI 5500 you are absolutely guarantee of accurate and reliable results. Training and consultation are included in the price. However, if you would still miss something, you have online technical assistance and the option of accredited calibration or pre-paid service.

Configure your own device, according to your requirements and needs. If you are not sure about the configuration, make the necessary information about the processed materials in the notes. Thanks to this information, we are able to create several offers depending on the equipment and after consultation you can choose according to your needs. If you need a comparison for tenders, we will be happy to help you find an alternative product from the Dynisco portfolio.

If you need more information do not hesitate to contact us.

The Dynisco LMFI 5500 series capillary Melt Flow Indexer have an optional configuration and can be ordered as a retrofit at any time.

Developed for processors to simply obtain detailed analytics and provides the ablility to correlate laboratory and production

Developed for processors to simply obtain detailed analytics and provides the ablility to correlate laboratory and production

rheological instruments for all devices globally on one single cloud dashboard and see any instrument around the world in real-time 24 hours a day, 7 days a week, 365 days a year.

The Digital Encoder provides a high precision measurement of piston displacement during Method A/B and B tests.

Cuts samples automatically at defined cut times of Method A and Method A/B Testing. Will also cut sample at end of pre-heat melt time of a test, regardless of method. Leads to more consistent sample cutting than cutting by hand.

| Melt flow index: | MFR - Melt Flow Rate [g/10min] |

|---|---|

| Melt flow index: | MVR - Melt Volume Rate [ccm/10min] |

| Melt density: | MD - Melt Density [g/ccm] |

| Intrinsic viscosity (PET): | IV - Instristic viscosity [dl/g] |

| Shear Viscosity: | Shear Viscosity [Pa.s] |

| Shear rate: | Shear Rate [1/s] |

| Meets standards: | ISO1133-1, ISO1133-2, ASTM D1238 & D3364, BS2782, DIN 53735, JIS K7210 |

|---|---|

| Operating temperature: | Max. 400°C |

| Temperature control accuracy: | ±0.10°C |

| Timer accuracy: | 0.001 s |

| Accuracy of digital encoder: | ±0.025mm |

| Display: | 7" touch screen; 130° viewing angle ; 800 x 480 resolution |

| Weights: | Aluminum, Stainless or Plated Steel 0.325 to 31.6 Kg |

| Communication: |

- 4x USB Port |

| Gravity correction: | YES |

| Expert Mode: | YES |

| Optional colour scheme: | YES |

| Dynisco Cloud: | YES |

| Dynisco Service Care: | YES |

| Adjustable PID control: | YES |

| Overall Dimensions, Base Model: | 13W x 21D x 20H in. (33W x 53D x 51H cm) |

|---|---|

| Weight, Base Model: | 47 lbs. (21.3 Kg) |

| Shipping Weight, Base Model with Weights: | 180 lbs. (81.8 Kg) |

| System Voltage: | 100-120Vac 50/60Hz or 220-240Vac 50/60Hz, 500VA, + 5% , 1 single phase |

| Power: | 500W max., 100W typical at set point |

Accessories can be ordered separately or as a complete set in the form of a complete "black-box" case.

This tool is used to remove the capillary from the melt flow indexer barrek before the cleaning process. The piston to remove the capillary has to be inserted from the bottom side of the barrel and then the capillary is pushed upwards out of the instrument. For instruments that have an automatic cut-off system, a tool code HEX-030 must be used.

This tool is used to remove the capillary from the barrel of the melt flow indexer with AutoCut before the cleaning process. The piston is inserted from the botttom of the barrel to remove the capillary, and then the capillary is pushed upwards out of the instrument.

This tool is used to fill and pack polymer samples into the barrel of the melt flow indexer and can be used with both types of powder or pellets or other types of polymers.

This tool is used to clean the chamber of melt flow indexer films and residue. One or two cotton patches are placed on the tool and the walls of the melt flow indexer barrel are cleaned by moving up and down. The capillary must be removed during this cleaning process, otherwise there is a risk of damage to the capillary.

Glass beaker for measuring the sample. Can be used for powder mixtures and granulates.

The swivel head of the pin vise (drill body) offers comfortable operation. Thanks to the double-ended pliers, different drill bit sizes can be stored. For better control, the pin vise body is made of grooved aluminium. Under the swivel part of the handle, there is an additional pincer, which is suitable for larger drill bits. The flared end of the pin vise body is used for hanging in the accessory rack

Copper brush for cleaning residue in the melt flow indexers barrel. Its thread is in inches and is compatible only with the original handle supplied with the instrument or can be reordered according to part number:0051-47. Or use the replacement:B0555CZ

The copper brush with extended adapter is used for manual cleaning of thick residues and burns in the barrel of a melt flow indexer or rheometer. Due to the softness of the material, you do not have to worry about damaging the instrument barrel. Thanks to the extended length, it lasts longer and removes more dirt per cleaning than standard brushes. It is mainly ideal for materials such as PET/PET/PC and additives that cause burns due to residual moisture, for example, and is very difficult to clean with cotton patches .

Standard capillary for Dynisco plastometer with an inner diameter of 0.95 mm and a length of 8 mm. The capillary is identical on both sides and is coated with a layer of Wolram Carbide, which gives the capillaries greater hardness and longer life. The capillary is used for all standard polymeric materials up to a flow index range of 0.1 [g / 10min] to 80 [g / 10min]. For higher indices, we recommend using a so-called half-capillary with half dimensions.

The half capillary is used for polymeric materials with very low viscosity. These materials, which achieve flow indices higher than 80 [g / 10min], will slow down and their testing will be no problem. If you are going to use a half capillary, you need to adjust the capillary plastometer settings and record this change in settings.

Cylindrical certified calibre for checking the capillary to the Dynisco melt flow indexer. The green end of the caliper must pass through the inner diameter of the capillary but the red end of the caliber must not pass through the diameter of the capillary. If the red end of the roller gauge passes through the capillary, it means that the capillary's inner diameter does not meet the required specifications and must be replaced.

Knife for manual cutting of the sample from the capillary melt flow indexer and for subsequent cleaning of the capillary. It is made of high quality wooden handle and mild steel, which guarantees flexible blade bending and ensures comfortable cutting of the sample.

The LMI accessory rack is used to store hot or used tools that are hung in the rack. After cooling, the individual elements can be cleaned. The rack helps to keep the workbench tidy and minimise the risk of injury.

Certified measuring piston for Dynisco capillary plastometer with a declared weight of 100g. The piston contains 3 marked positions (lines) that show the position of the start of sampling and the end of sampling in the range of 30 mm according to ISO 1133 and a distance of 1 inch for ASTM D1238.

The stainless steel capillary brush with a diameter of 2.2 mm is the ideal tool for materials that are difficult to clean with heat. Thanks to its solid construction, it is very easy and comfortable to use despite its miniature size. The brush confidently cleans all residual polymer deposits inside the capillary and thus ensures perfect measurement results.

Cleaning wheels for laboratory instruments have high cotton quality and low dust resistance. As a result, you will always have the instrument quickly and conveniently cleaned of all polymer deposits inside the barrel. Thanks to the 100% cotton, the polymer does not smear on the barrel wall, but stays on the cotton roller, which does not tear and leaves no lint.

It belongs to the group of scales with touch control. The biggest advantage of the Quintix series is easy operation via a color touch screen. Serious applications are clearly displayed with icons, as is usual today for "smart devices". Another plus of this series is excellent data communication. Each Quintix scale is equipped with a mini USB data output with Plug & Play technology.

Standard laboratory scales with clear display, simple operation and five operating modes. The advantage of this series is the PRE-TARE function (when activated, the stored weight is automatically deducted from the current measured weight).

The High Flow Plug is used as a seal against leakage of a filled barrel of a polymer that has a very low viscosity.

Cordless angle drill for easy and quick cleaning of the melt flow indexer barrel. In combination with the cleaning mandrel with replaceable tip, this set is the best helper, which also has a positive effect on the accuracy and the results provided. It also includes an extension mandrel for attaching the brush.

Cordless angle drill for easy and quick cleaning of the melt flow indexer barrel. In combination with the cleaning mandrel with replaceable tip, this set is the best helper, which also has a positive effect on the accuracy and the results provided.

The 8.5in (22cm) cleaning rod is used in combination with the cleaning tip and the cotton cleaning wheels. With this combination, you can clean the chamber quickly and easily using the cordless drill, with a positive effect on the accuracy of the instrument.

The barrel cleaning tip is used in combination with cotton cleaning patches and an extension cleaning rod. The tips are replaceable and made of aluminium to prevent damage to the melt flow indexer barrel. Nevertheless, this cleaning tip is only used with cotton patches.

The inspection mirror is used for inspection when cleaning the device, thanks to the telescopic handle you can easily and without risk get everywhere where you would otherwise have to lean or lean towards places with high temperature and thus avoid the risk of burns.

The new LaVa Suite software is now available for the LMI 5000 Series capillary plastometers. It offers complete and easy management when collecting, storing and working with digital data provided by the capillary plastometer. Lava Suite ™ software enables additional generated measurement results, filtering using identifiers and comparison of individual measurements on a larger scale, including time horizons.

Integrate and aggregate data from existing Dynisco products such as our LMI5000 & LMI4004 melt flow indexers, our LCR7000 capillary rheometer, and instrumentation like our UPR900 process indicator via the Dynisco Edge Device. With the Edge Device you have a single board computer that helps you better understand and manage:

The universally applicable Memmert laboratory dryer is a classic temperature control device in the field of research, science and materials testing. Technologically improved construction made of high quality and easy to clean stainless steel. It has ventilation and control technology (optional), protection against overheating and precisely tuned heating technology.

Specifically designed for the thermoplastics resin industry. The ViscoIndicator duplicates the test conditions of a laboratory Melt Flow Rate (MFR) tester or capillary rheometer. Melt viscosity measurements such as melt flow rate and Intrinsic viscosity are primary specifications of thermoplastic resins.

Dont forget- our ViscoIndicator is IoT enabled. The IoT native software of the ViscoIndicator allows for real-time access to your testing information.With the Dynisco Cloud Connect Subscription, you get comprehensive access of rheological data, correlations, and dashboards. This interface allows for a complete “Window into the Process” providing valuable insight to your polymer process.

The ViscoSensor provides continuous measurements of the melt flow rate or apparent viscosity directly on the manufacturing process. The ViscoSensor system consists of two parts: a Viscosensor Rheologic Sensing Unit (RSU), connected directly to the process, and a Rheologic Control Unit that controls the ViscoSensor test parameters, provides outputs of computed results, and provides communications to an external distributed control system when required.

Specifically designed for the thermoplastics resin industry, the Dynisco CMR series can be configured to measure melt flow rate, high/low load melt flow rate, apparent viscosities, or to perform other customer defined tests.The CMR system consists of two parts: a rheometer head connected directly to the process which samples, conditions, and measures the melt flow of the resin, and an RCU (Rheometer Control Unit) that controls the CMR test parameters (temperature, pressure, rate), and provides outputs of computed results, and communications to an external distributed control system when required.

Specifically designed for the synthetic fiber production industry, the Dynisco FCR-R series can be configured to measure a range of apparent shear viscosities, dual melt flow rate, simultaneous melt flow rate and extensional viscosities using the Cogswell Equations. The FCR-R system consists of two parts: a rheometer head and a rheometer control unit (RCU). The rheometer head is connected directly to the process which samples, conditions, and measures the melt viscosity of the molten resin through two separate dies. The RCU controls the rheometer test parameters (temperature, pressure and rate) and takes in data from the measurement head as well as provides outputs of computed results.

The advanced LOI Limiting Oxygen Index Chamber accurately determines the relative flammability of plastics and other materials. It conforms to ASTM D2863 and ISO 4589-1, ISO 4589-2 standards and provides a means for safely determining the relative flammability of materials by measuring the minimum oxygen concentration that will support combustion. The test specimens are burned in a precisely controlled atmosphere of nitrogen and oxygen. The operator adjusts the supply gases and uses the flowmeter readings to calculate the oxygen index.

The Dynisco MiniGran Lab Granulator is designed for the granulation of small sprues. With its very compact dimensions, this granulator can be accommodated almost anywhere and therefore is very suitable for laboratory applications. The granulator is suitable for all kind of plastic materials, due to the low rotor speed the plastic materials are processed to high-quality, low-dust regrind.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.