Maax 100S / 400S / 600S

Extrusion gear pump and melt pump system for the polymer extrusion industry

The maax® automation system simplifies operation, control, adjustment, and monitoring of the operating parameters. This guarantees optimum protection and operation of the extrusion gear pump system, melt pump system, and screen changer. Process and operational reliability of the entire system is increased. The maax® 100S automation system is the ideal solution for integrating melt pumps and screen changers into the extrusion line. maax® 400S is for upgrading coextrusion lines. The maax® 600S automation system is the ideal solution for equipping complete and complex extrusion and compounding plants in the polymer extrusion industry.

Simple and clear operation of the line-start and stop proceures

Increased productivity, by saving recipies in parameter lists

Rapid and precise control of extruder and pump speed, depending on application

Integrated temperature control of system components

Quick error detection by plain text messages

Scalable visualisation of various operating parameters in a trend display

Additional for maax® 100S/400S/600S: configurable System and Software configuration

Maax 3S

Automation system for retrofitting in extrusion lines

The automation system maax® 3S simplifies the operation, control, regulation, and monitoring of the operating parameters. Production data are displayed transparently and operation is simple and intuitive. Process and production safety of the line are increased. The maax® 3S automation system is particularly suitable for the retrofitting of gear pumps or screen changers in extrusion lines.

Simple and clear operation of the start-up and shutdown routines

Modular expansion to include screen changer controllers

Quick and precise control of the extruder or pump speeds

Independent start-up and production control of the pump speed

Integrated temperature control of the line components

Fast troubleshooting thanks to plain text messages

Maxx BF

Automatic self cleaning backflush screen changer for filtration systems

Maax® BF is MAAG’s well-proven control system for the fully automatic backflush screen changers. It allows the processor of highly contaminated polymer melts simple handling of the backflush screen changer and fully automatic screen cleaning for multiple use of the built-in screens. The automation system is particularly well suited for retrofitting extrusion lines with automatic self cleaning screen changers with backflush function. Operation, control, regulation, and monitoring of operating parameters are simplified. Process and operation reliability of the filtration systems of the entire system are increased.

Simple and clear operation of filter and system functions

Increased productivity through storage of recipes in parameter lists

Integrated temperature control of the system components

Rapid error detection via clear text messages

Scalable visualization of different operation parameters in a trend display

Increased productivity

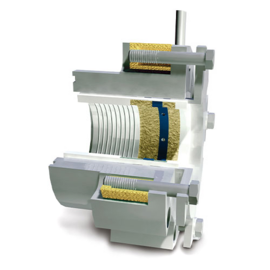

Vispac

Seal for polymer gear pumps and polymer pump systems and applications

High reliability and functionality are crucial for a seal in the polymer application discharging process for guaranteeing optimized product quality and line availability. The vispac® shaft seal is known for its robustness and reliability and especially for its easy handling. This low-maintenance seal is a proven combination of the viscoseal system and sealed packing glands for polymer pump systems.

Extremely large range of applications

Reliability and safety

Low wear and low maintenance

Simple and reliable adjustment of the seal control pressure

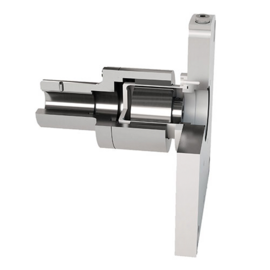

Magnetic Coupling

Sealed design with our double containment shell for chemical pumps as a industrial application

MAAG offers Magnetic Couplings with our double containment shell for chemical pumps. The magnetic couplings provide a hermetically sealed design for chemical transfer pumps and is virtually maintenance free. The couplings come in special designs for industrial applications with suction pressures up to 200 bar.