Model 510 Hammer Union Pressure Transmitter

Oil Well Drilling, Cementing, Fracturing and Acidizing

Our exclusive semi flush design provides a lower cavity volume to prevent clogging. This eliminates the need for tedious cleaning, especially in cementing applications.

Inquiry system

Configure your own product according to your requirements and needs. If you are unsure of the configuration, provide us in the notes the necessary information about the existing sensor or product, even a competitor. We will be happy to help you find an alternative Viatran product. If your request is urgent, let us know. We will do our best to help you resolve this situation to your satisfaction as quickly as possible. If we have all the information, we are able to offer a model with minor differences, which is in stock and you can have another product available the next day.

If you need more information do not hesitate to contact us.

Viatran Configuration Code:

Model 510 Hammer Union Pressure Transmitter

Oil Well Drilling, Cementing, Fracturing and Acidizing

Our exclusive semi flush design provides a lower cavity volume to prevent clogging. This eliminates the need for tedious cleaning, especially in cementing applications.

Performance characteristics

| Full Scale Pressure Ranges |

0-5K, 6K, 10K, 15K, 20K PSIS (0-345, 414, 689, 1034, 1379 bar) |

| Combined Accuracy (BFSL) |

≤ ± 0.25% FSO (Non-Linearity, Hysteresis & Repeatability) |

| Full Scale Output (FSO) |

16.00 mA ±1% FSO |

| Zero Balance |

4 mA ±1% FSO |

| Long-Term Stability |

≤±0.25% FSO per 6 months |

| Response Time |

≤2.5 mSec to reach 90% of FSO |

| Compensated Temperature |

40°F to 140°F (4°C to 60°C) |

| Operating Temperature |

-40°F to 185°F (-40°C to 85°C) |

| Storage Temperature Limits |

-67°F to 302°F (-55°C to 150°C) |

| Temperature Effect on Zero |

≤±1% FSO per 100°F (37°C) |

| Temperature Effect on Zero |

≤±1% FSO per 100°F (37°C) |

| |

|

Electrical characteristics

| Output Signal |

4 - 20 mA at 70°F (21°C) |

| Supply Voltage |

10.5 to 28 Vdc |

| Power Supply Regulation Effect (Calibrated at 12 Vdc) |

≤±0.01% FSO per Volt |

| Loop / Load Impedance |

750 Ohms at 24 Vdc decreasing linearly to 0 Ohms @ 9 Vdc |

| Range Calibration Signal |

100% of FSPR |

|

Calibration Power

|

7.5 to 28 Vdc at 15 mA nominal |

| Calibration Signal Accuracy |

≤±0.2% FSO. The exact signal to pressure correlation is provided with each unit |

| Circuit Protection |

Varistor protected across the input leads for surges to 1000V at 50 microseconds |

|

Bridge Resistance

|

10K Ohms nominal |

| Calibration Power Supply Voltage |

8.5 -28 VDC |

| Calibration Signal Accuracy |

Readings on calibration certificate are within ±0.2% FSO of actual Cal signal output |

| Bridge Resistance |

10K ohms, nominal |

| Standard Electrical Connection |

Mates with 6 pin, Hermetic, Box Mount, Shell Size 10, MIL-C-26482 bendix type connector |

PIN OUTS

|

PIN A+ Power / Signal

PIN B- Power / Signal

PIN CNo Connection

PIN DNo Connection

PIN E+ Calibration

PIN F- Calibration

|

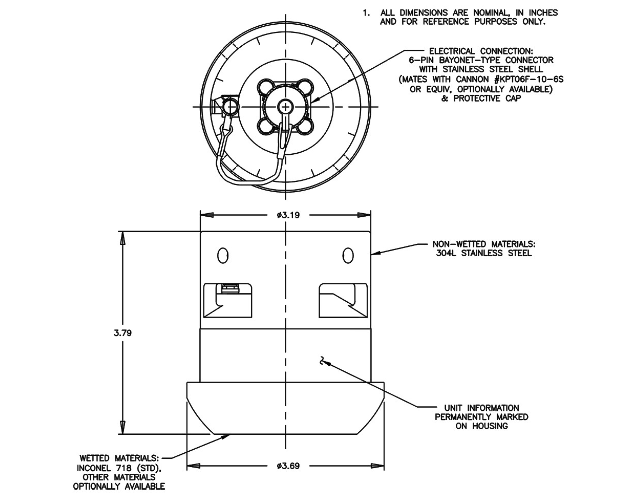

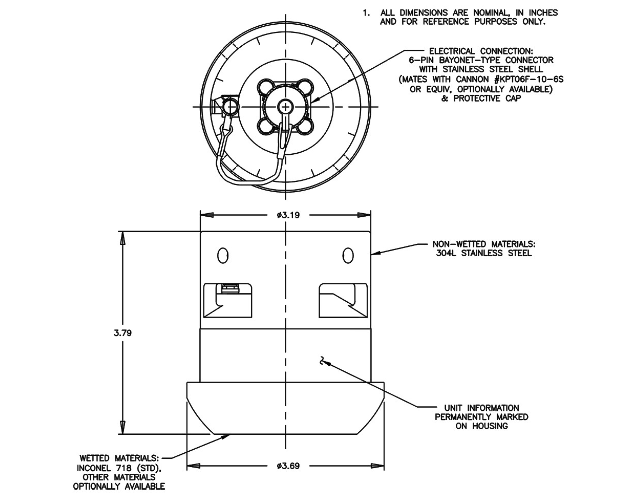

Mechanical characteristics

| Standard Pressure Port |

Male hammer union 2 inch #1502 |

| Pressure Cavity Volume |

Standard: 0.45 cubic inches |

| Zero Effect from Installation |

Option "TP" : 0.22 cubic inches |

| Shock Sensitivity |

1000 g, 0.5 ms half sine wave pulse shall not cause change in calibration |

| Proof Pressure |

1.67X range or 22,500 PSI max |

| Burst Pressure |

3 Times full scale pressure range, limited by union #1502: 22.5K PSI |

Materials of Construction

| Wetted Materials |

NACE compliant Inconel 718 (MR0175/ISO 15156-3:2009(E)) |

| Enclosure Material |

304 Stainless Steel |

| Identification |

Laser marked on body of unit |

| Enclosure Rating |

IP68*, NEMA 6P* |

| Weight |

5.6 lbs. nominal |

| * Pending approvals |

|

Options

| DC |

Male hammer union 2 inch #1502 |

| DG |

Standard: 0.45 cubic inches |

| DH |

Option "TP" : 0.22 cubic inches |

| DN |

1000 g, 0.5 ms half sine wave pulse shall not cause change in calibration |

| EA |

1.67X range or 22,500 PSI max |

| EH |

3 Times full scale pressure range, limited by union #1502: 22.5K PSI |

| LW |

Narrow adapter for banding |

| NA |

Carrying handle attached |

| NH |

Customer specific identification |

| NP |

Protective ring cage |

| NQ |

Protective criss-cross cage |

| Z() |

Special connectors |

| TW |

Russia Intrinsic Safety and Non-Sparking |

Drawings

4-20 mA output, 2" 1502 fitting, Hazardous Location Approvals

511 is Viatran's state of the art hammer union pressure transmitter with industry exclusive features that were developed in direct response to requests from the field. Included in these features is a voltage powered shunt cal, ability to calibrate and track pressure spikes using HART® Communicators or DevCom2000-Lite software and packaged in a patented* housing which can withstand extreme vibration and abusive impact and still perform to specification.

Oil Well Drilling, Cementing, Fracturing and Acidizing

Our exclusive semi flush design provides a lower cavity volume to prevent clogging. This eliminates the need for tedious cleaning, especially in cementing applications.

4-20 mA output, 2" 2002 fitting, Hazardous Location Approval Options

Viatran's Model 520 Hammer Union Pressure Transmitter offers superior construction and the rugged performance that we have built our reputation on.

Model 811 Hammer Union Pressure Transducer

mV output, 2" Figure 1502 fitting

811 is Viatran's state of the art hammer union pressure transducer with a millivolt output that was developed in direct response to requests from the field. Built with a patented* housing which can withstand extreme vibration, abusive impact and will continue to perform to specification.

Ruggedized Connector Cables sold separately.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety. More information

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety. More information

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results. More information

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results. More information

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support. More information

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support. More information

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support. More information

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support. More information