- MDA Series

- PT Series

- MDT series

- SPX series

- Echo Series

- Vertex Series

- Industrial series

- Injection Series

- Mercury Free Series

EPR4 Push Rod Sensors

The EPR4 series are sensors with ± 0.5% accuracy ideal for food or medical applications requiring easy installation, repeatability and reliability. Technology Push Rod design is especially suitable for food or medical applications with the possibility of filled systems. EPR4 provide an industry standard in the form of an amplified 4-20 mA signal designed to work with DCS and PLC. The EPR4 model is available in various pressure variants.

Better than ± 0.5% accuracy

Fixed rod construction

Usable up to 400 ° C

Welded stainless steel construction

4-20 mA output signal

Internal calibration 80%

MDA435

MDA435 - Sensor with flexible and exposed capillary

The sensors of this series MDA435 have a flexible capillary with an exposed mounting tip, which is used in an area where it is not possible to install a standard sensor with a flexible capillary and a rigid stem. Individual models have different accuracy. Model 435 has an accuracy of 0.50% of the pressure range. Power supply with 10-12 V DC and membrane made of 15-5 PH material and coated with DyMAX layer. The length of the flexible capillary can be optionally configured.

Output signal 3.33 mV/V

Accuracy better than 0.50%

Power supply 10-12 Vdc

6 Pin connector

Shunt calibration

PT435A

PT435A - Sensor with flexible and exposed capillary

The PT435A series model have been designed for applications where installation space is extremely limited. The exposed part of the capillary allows a bend with a small radius of 3 mm. The specially developed design of the sensor tip facilitates the installation of the sensor in very cramped and confined spaces, where it is not possible to install a standard sensor with a fixed rod or flexible capillary.

0 - 30,000 PSI

Output signal 3.33 mV / V

Accuracy ±0.25%

Power supply 10-12 Vdc

Units - PSI

8 Pin connector

Shunt calibration

Excellent thermal stability and repeatability

Exposed, bendable capillar

MDT435

MDT435 - Sensor with flexible and exposed capillary

Sensor with an amplifier (signal converter) in a version with flexible capillary and exposed membrane. Scanning accuracy better than 0.50% of the range. Power supply via 10-36 Vdc. Membrane made of 15-5 PH material and coated with DyMAX®. The length of the fixed rod can be made and adjusted to the required size.

Accuracy better than 0.25%

Power supply 10 -36 V dc

6 Pin connector

R-Cal calibration

Up to 400 °C

For small areas

Flexible capillary

Electrical built-in calibration

Various high level outputs

MDA467

MDA467 - Sensor with flexible and exposed capillary

The sensors of this MDA467 series have a flexible capillary with an exposed mounting tip, which is used in an area where it is not possible to install a standard sensor with a flexible capillary and a rigid stem. Individual models have different accuracy. Model 467 has an accuracy of 1.00% of the pressure range. Power supply with 10-12 V DC and membrane made of 15-5 PH material and coated with DyMAX layer. The length of the flexible capillary can be optionally configured.

Output signal 3.33 mV/V

Accuracy better than 1.00%

Power supply 10-12 Vdc

6 Pin connector

Shunt calibration

PT467E

PT467E - Sensor with flexible and exposed capillary

The PT467E models have been designed for applications where installation space is extremely limited. The exposed part of the capillary allows a bend with a small radius of 3 mm. The specially developed design of the sensor tip facilitates the installation of the sensor in very cramped and confined spaces, where it is not possible to install a standard sensor with a fixed rod or flexible capillary.

0 - 30,000 PSI

Output signal 3.33 mV / V

Accuracy ±0.5%

Power supply 10-12 Vdc

Units - PSI

6 Pin connector

Shunt calibration

Excellent thermal stability and repeatability

Exposed, bendable capillar

PT467XL

PT467XL- Pressure sensor with flexible and exposed capillary In a version with a more durable membrane(XL).

The PT467XL series of pressure transmitters are the ideal choice for applications with high accuracy and minimal mounting space. The PT 467XL models have an accuracy of ± 0.5% of range and an exposed capillary with a diameter of 1.5 mm, which allows bending in a radius of 1/16 inch. The sensors are supplied with a Dymax® membrane, which ensures an increase in wear resistance and thus a longer service life. Sensors marked XL have a protector (flexible capillary) up to the tip of the sensor.

Durable membrane XL

0 - 30,000 PSI

Output signal 3.33 mV / V

Accuracy ±0.25%

Power supply 10-12 Vdc

Units - PSI

6 Pin connector

Shunt calibration

Excellent thermal stability and repeatability

Exposed, bendable capillar

MDT467

MDT467 - Sensor with flexible and exposed capillary

Sensor with amplifier (signal converter) in version with flexible capillary and exposed membrane. Scanning accuracy better than 1.00% of range. Power supply via 10-36 Vdc. Membrane made of 15-5 PH material and coated with DyMAX®. The length of the fixed rod can be made and adjusted to the required size.

Accuracy better than 0.5%

Power supply 10 -36 V dc

6 Pin connector

R-Cal calibration

Up to 400 °C

For small areas

Flexible capillary

Electrical built-in calibration

Various high level outputs

PT415D (NaK)

PT415D - Washable sensor with rigid stem and NaK filling.

The PT415D pressure transmitter with accuracy of better than ±0.5% is the ideal choice for food and medical applications that require high accuracy and easy maintenance. It is a washable sensor with insulated wiring type 1/2-14 NPT or an optional 6-pin hermetically insulated bendix connector. PT 415D contains a high temperature fill (NaK, sodium potassium) and an Inconel membrane. Meets FDA and USDA hygiene regulations and requirements.

Output signal 3.33mV/V

Accuracy better than 0.5%

Washable construction

FDA Certification - (GRAS) for food and pharmaceutical applications

Power supply 10-12 Vdc

Units - PSI

Shunt calibration

Optional 6-pin connector

PT418 | PT419 | TPT419 (Oil)

PT418 - Sensor with rigid stem

PT419 - Sensor with rigid stem and flexible stem

TPT419 - Combined sensor with rigid stem, flexible stem and built-in temperature sensor

Model PT418 | PT419 | TPT419 Better than ±0.5% accuracy uses mineral oil as a filler, which meets the requirements of the FDA and USDA and at the same time allows accurate pressure sensing in processes where it is not possible to use mercury fillings. These models are ideal for medical and food or packaging applications.

Output signal 3.33 mV/V

Accuracy better than 0.5%

Special fill material

Meets the requirements of the FDA and USDA

Power supply 10-12 Vdc

Units - PSI

6 Pin connector

Shunt calibration

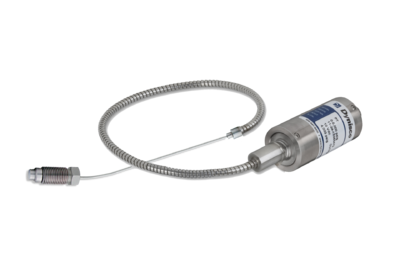

PT4654XL

The PT4654XL models represent an optimal solution for precise melt pressure measurement in nozzles or distribution channels within injection molding applications.

The flexible capillary extends from its electronic housing to the positioned tip in the machine melt, ensuring exceptional durability and prolonged sensor lifespan thanks to its robust construction.

1 "bending radius

Inconel 718 membrane

Cap nut for easy installation

Scanning accuracy ± 0.5%

Usable up to 400°C

Zero and range calibration

4-20mA output signal

PT4655XL

The PT4655XL models represent an optimal solution for precise melt pressure measurement in nozzles or distribution channels within injection molding applications.

The flexible capillary extends from its electronic housing to the positioned tip in the machine melt, ensuring exceptional durability and prolonged sensor lifespan thanks to its robust construction.

1 "bending radius

Inconel 718 membrane

Cap nut for easy installation

Scanning accuracy ± 0.5%

Usable up to 400°C

Zero and range calibration

Optional output signal